Hydraulic cutting device for deep sea cutting sleeve

A cutting device and hydraulic technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of low cutting efficiency, insufficient blade life, complicated operation, etc., and achieve simple structure, convenient use and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

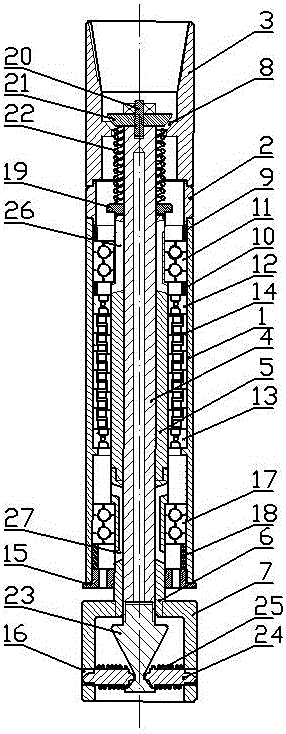

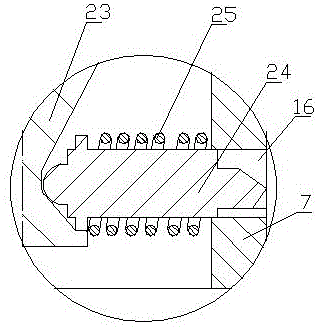

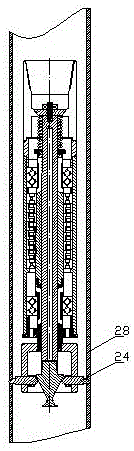

[0022] The hydraulic cutting device for deep-sea cutting casing includes a casing 1 , a connecting cylinder 2 , a joint 3 , a hollow shaft 4 , an upper sleeve 5 , a middle sleeve 6 and a lower sleeve 7 . A joint 3 is threadedly mounted on the top of the shell 1 through the connecting cylinder 2; the inner wall of the joint 3 is provided with a blocking hole 8, and the blocking hole 8 is a tapered hole. An upper sleeve 5 and a middle sleeve 6 are arranged inside the casing 1 below the flow blocking hole 8 , and the upper sleeve 5 and the middle sleeve 6 are threadedly connected. The upper sleeve 5 is equipped with an upper thrust bearing 11 through the spacer ring A9 and the spacer ring B10, and the upper sleeve 5 below the upper thrust bearing 11 is equipped with a turbine assembly 14 through a central bearing A12 and a central bearing B13. The turbine assembly 14 includes a rotor and stator.

[0023] The lower port of the shell 1 is threaded with a shell end cap 15, the lower e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap