Tail gas after-treatment assembly and system for natural gas engine

A tail gas post-treatment and natural gas technology, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, engine components, etc., can solve the problems of low exhaust gas temperature and cannot meet the catalyst carrier temperature, etc., and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

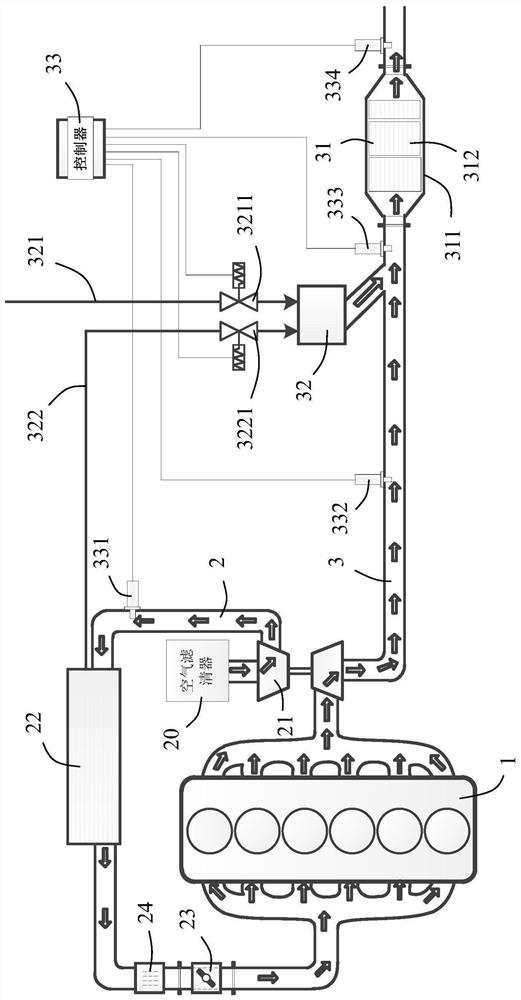

[0017] Please refer to figure 1 As shown, the present invention discloses a system of a natural gas engine, which includes a natural gas engine 1, an intake system 2 connected to the intake end of the natural gas engine 1, and an exhaust gas exhaust system connected to the outlet end of the natural gas engine 1. Processing system 3.

[0018] The intake system 2 includes a turbocharger 21, an air filter 22 connected upstream of the turbocharger 21, a supercharging intercooler 22 connected downstream of the turbocharger 21, and An electronic throttle valve 23 connected downstream of the supercharged intercooler 22 . The electronic throttle valve 23 is connected with the intake port of the natural gas engine 1 . In the illustrated embodiment of the present invention, the intake system 2 further includes a mixer 24 connected between the supercharged intercooler 22 and the electronic throttle 23 . The mixer 24 is used to mix the air flowing out of the charge intercooler 22 with the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap