Dish-washing machine heating control method and dish-washing machine

A technology for heating control and dishwashers, which is applied to dishwashers/washers for tableware, parts of dishwashers/rinse-washers for tableware, household cleaning devices, etc. Energy waste and other problems, to achieve the effect of improving work efficiency and cleaning rate, increasing temperature, and avoiding increased air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

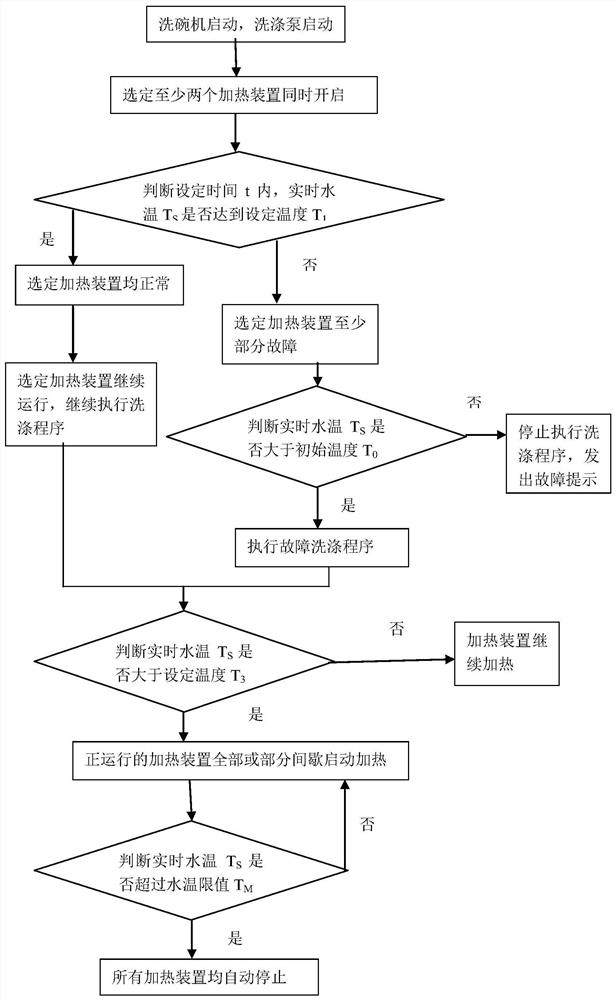

[0054] Such as figure 1 As shown, in a kind of dishwasher heating control method provided by the present invention, various parameters are involved, which are explained in detail below:

[0055] T 1 : set temperature; t: reach the set temperature T 1 time required; T 2 : set temperature; t 0 : Reach the set temperature T 2 time required; T 3 : set temperature; T M : Temperature limit; the above-mentioned parameters have been pre-set when setting the program.

[0056] T 0 : initial temperature; when the dishwasher starts the washing program, the temperature of the washing water is detected, and the detected value is recorded as the initial temperature T 0 .

[0057] T S : Real-time water temperature; real-time detection of the temperature of the washing water through the water temperature sensor.

[0058] In this example, T 1 3 M ,T 2 3 M , by setting detailed control parameters to make the dishwasher heating control more intelligent and automatic.

[0059] In this e

Embodiment 2

[0063] Such as figure 1 As shown, in a heating control method for a dishwasher provided by the present invention, the fault washing program of the dishwasher includes the following steps:

[0064] S1. Identify whether the selected heating devices are faulty;

[0065] S2. The heating device that has not been identified to be faulty continues to run, and continues to execute the washing program.

[0066] Specifically, an identification process in step S1 is specifically as follows:

[0067] Step S101, mark the selected heating device, turn on one of the marked heating devices, and judge t 0 Time real-time water temperature T S Whether it reaches the temperature T 2 ;

[0068] If not, it is judged that the heating device is faulty;

[0069] If so, it is judged that the heating device is normal.

[0070] Through the above settings, it can be clearly judged which of the selected heating devices is faulty, and the judgment result is accurate.

[0071] Another identification pro

Embodiment 3

[0086] The present invention also provides a dishwasher, including the heating control method of the dishwasher described in the above embodiments. By setting this control method, the heating control of the dishwasher is made more intelligent, and the efficiency of the dishwasher is improved. Work efficiency and convenience, while avoiding energy waste, reducing the number of parts, reducing the user's cost of use, and improving the user's experience.

[0087] Those skilled in the art can clearly understand that the steps of the above method can be stored in a computer storage medium in the form of a computer program, so the present invention also discloses a computer storage medium on which a computer program is stored, the When the computer program is executed by the processor, the steps of the above method can be realized. In addition, decomposing the steps of the above method into multiple modules for execution should also be understood as the content disclosed in the present

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap