Tray structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]For ease of understanding the concept of the invention, the invention is described below with reference to embodiments and the accompanying drawings.

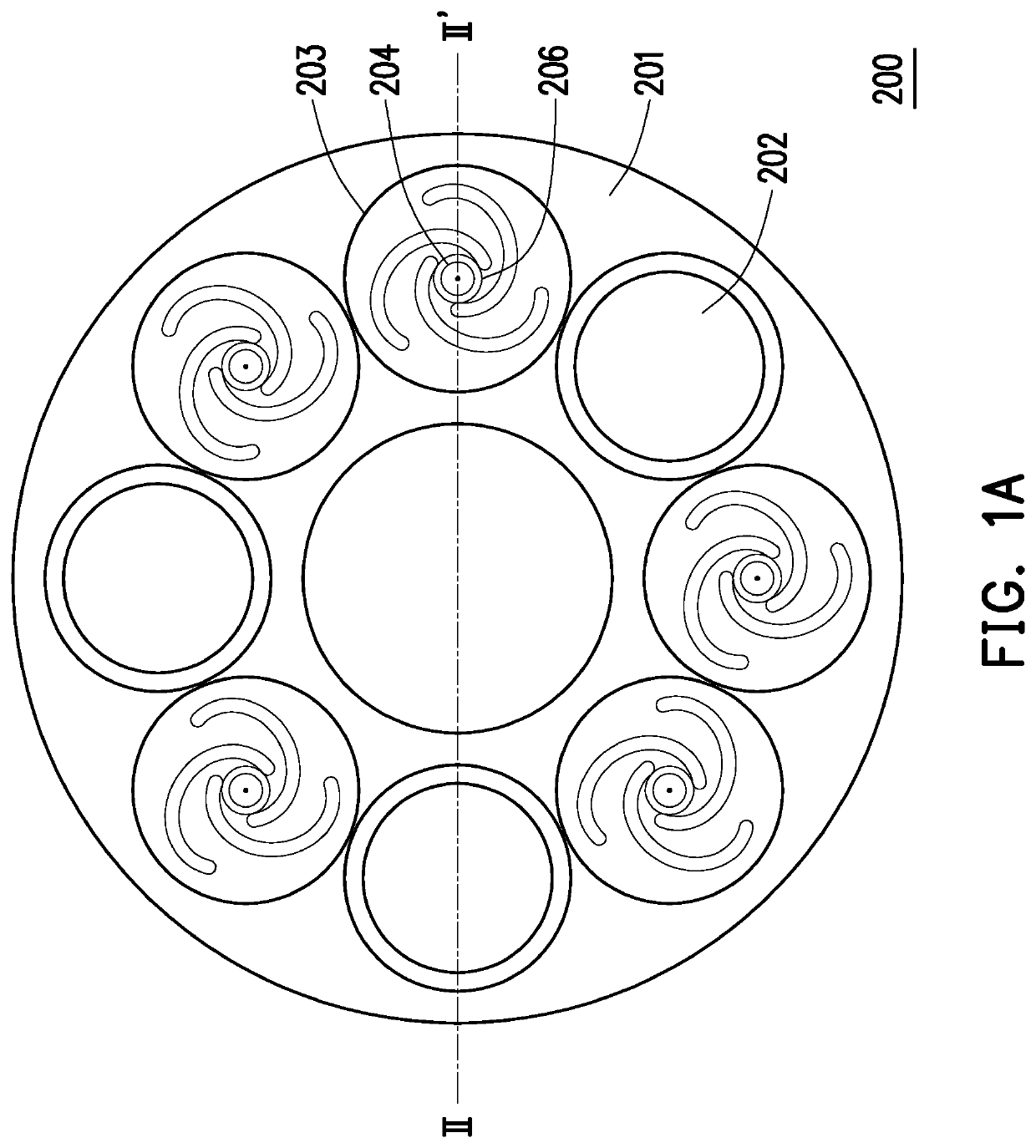

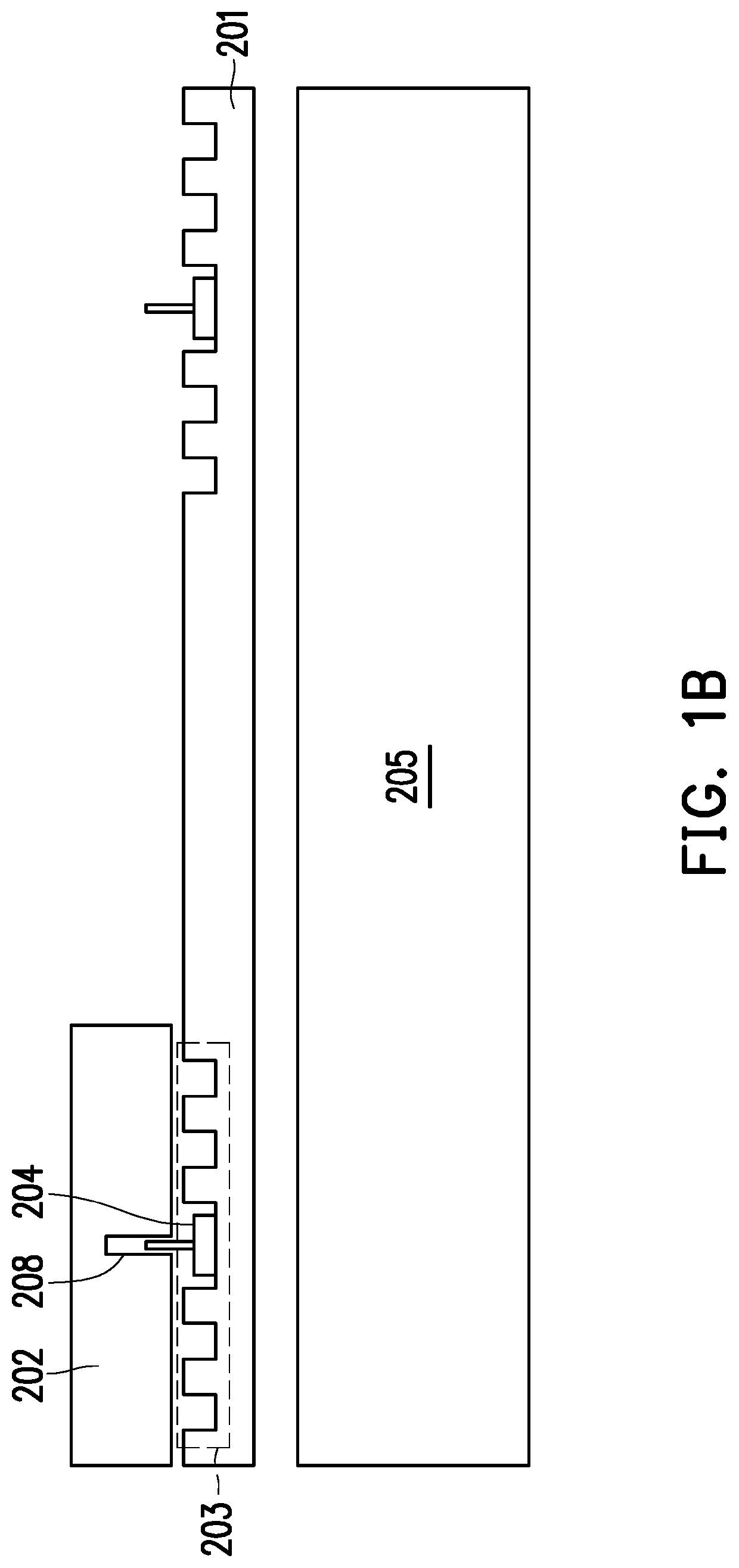

[0019]Please refer to FIGS. 1A and 1B. FIG. 1A is a tray structure according to an embodiment of the invention. FIG. 1B is a cross-sectional view taken along a dotted line II-IT when the tray structure of FIG. 1A is disposed on a deposition apparatus.

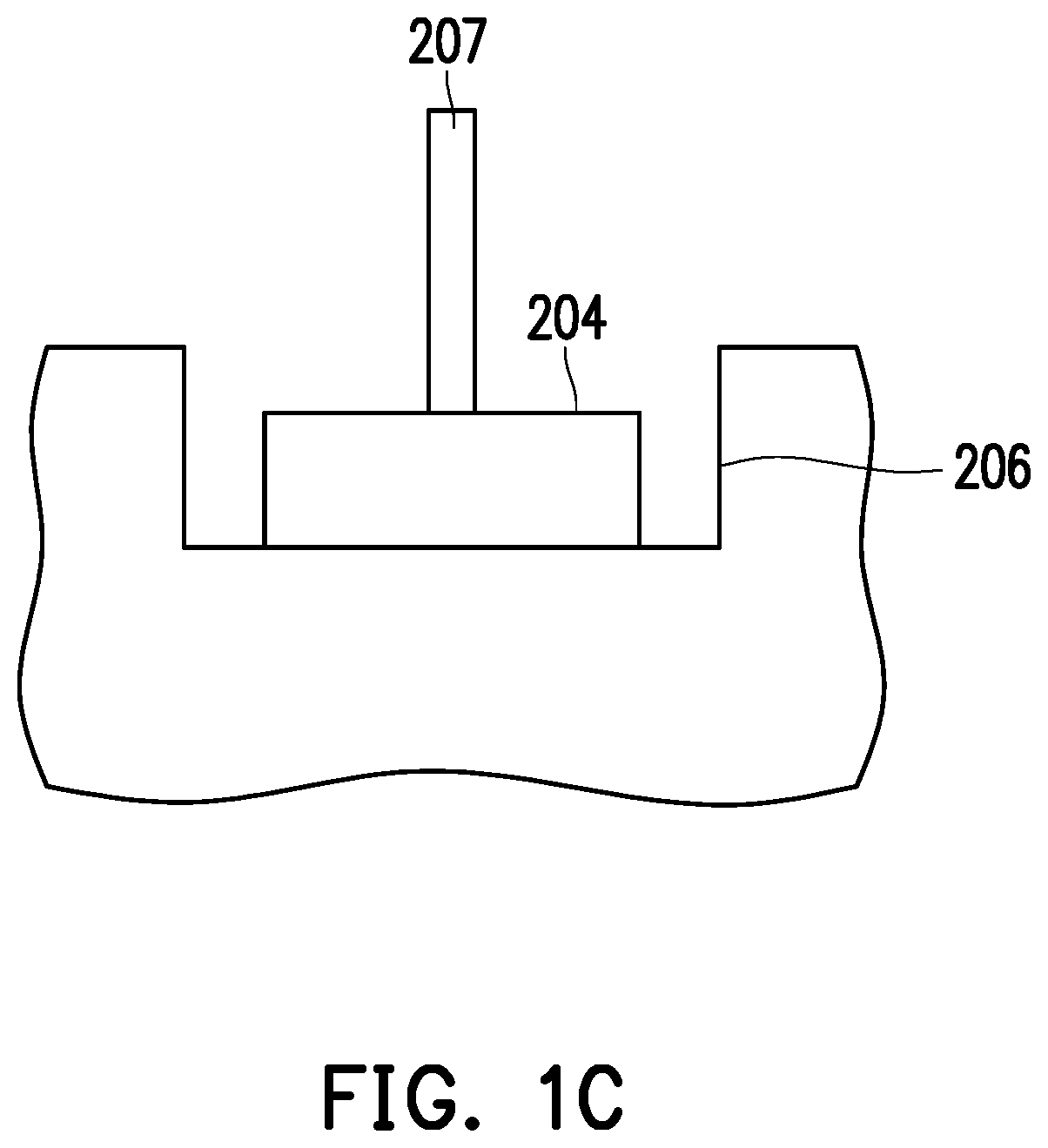

[0020]A tray structure 200 provided by the present embodiment includes a first tray 201 and a second tray 202. The first tray 201 includes a first carrying portion 203 and a heat-conducting structure 204. The first carrying portion 203 is disposed on a top surface of the first tray 201. The heat-conducting structure 204 is disposed in a recess 206 of a central region of the first carrying portion 203. The second tray 202 is disposed on the first carrying portion 203 and the heat-conducting structure 204. The tray structure 200 is adapted to be disposed on a deposition apparatus 205. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap