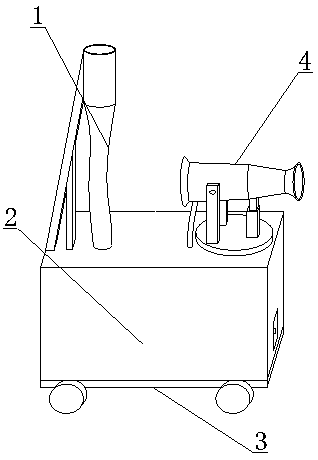

Dust collection device used at explosion site

A dust removal device and dust technology, which is applied in the direction of combination device, liquid separation agent, and dispersed particle separation, etc., can solve the problems of dust treatment, small working area of dust removal device, low dust removal efficiency, etc., and achieve easy operation, fast and effective adsorption Treatment, improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

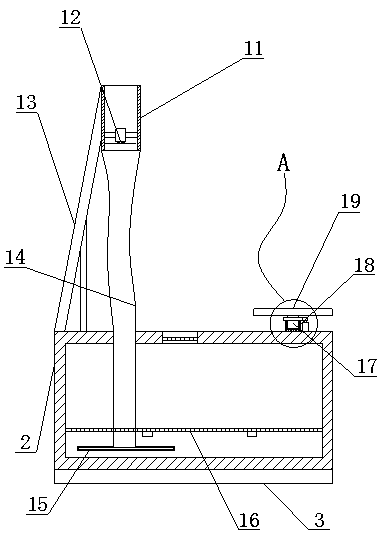

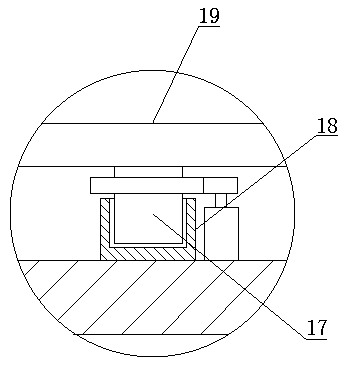

[0021] The specific implementation method: start the dust removal wind gun 4, the dust removal wind gun 4 sucks the water in the water tank 2 through the water pipe, and the dust removal wind gun 4 sprays the water mist in the air, starts the motor to rotate forward and reverse alternately, and then the motor passes through the pinion and The large gear drives the rotating column 17 to rotate forward and reverse alternately, the rotating column 17 carries the support plate 19 and the dust removal wind gun 4 to rotate forward and reverse alternately, start the electric lifting rod to move up and down alternately, and the electric lifting rod carries the dust removal wind gun 4 to spray The mouth moves up and down alternately, and then the dust removal air gun 4 sprays the water mist in the air at different spatial angles, the dust in the air meets the water mist and gathers and falls, thereby increasing the working area of the dust removal air gun 4 At this time, start the exhaus

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap