Grille for a cyclone vacuum

a vacuum cleaner and cyclone technology, applied in the field of vacuum cleaners, can solve the problems of reducing the dust-collection performance of the vacuum cleaner, and achieve the effect of improving the structure and preventing stagnant air regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

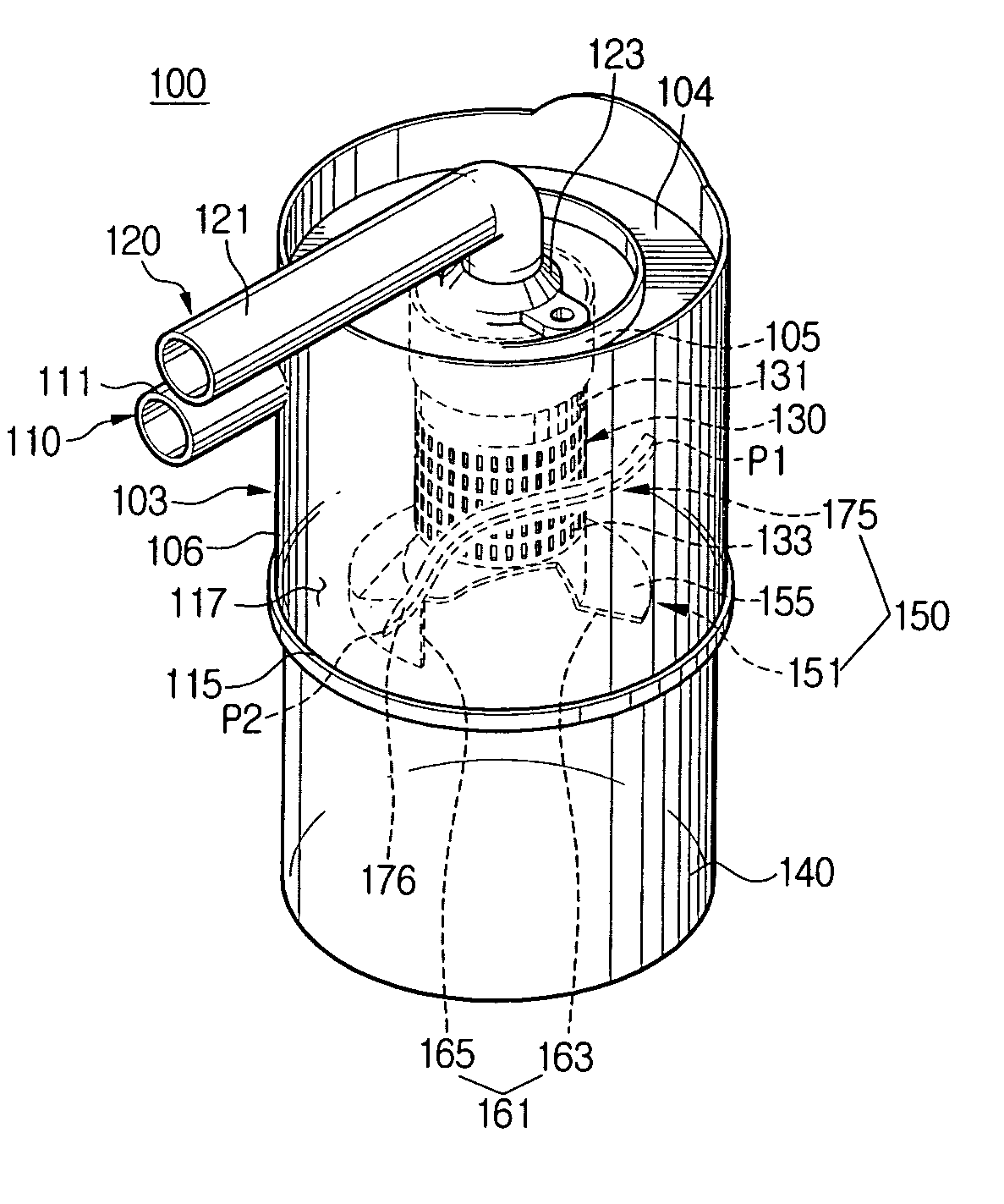

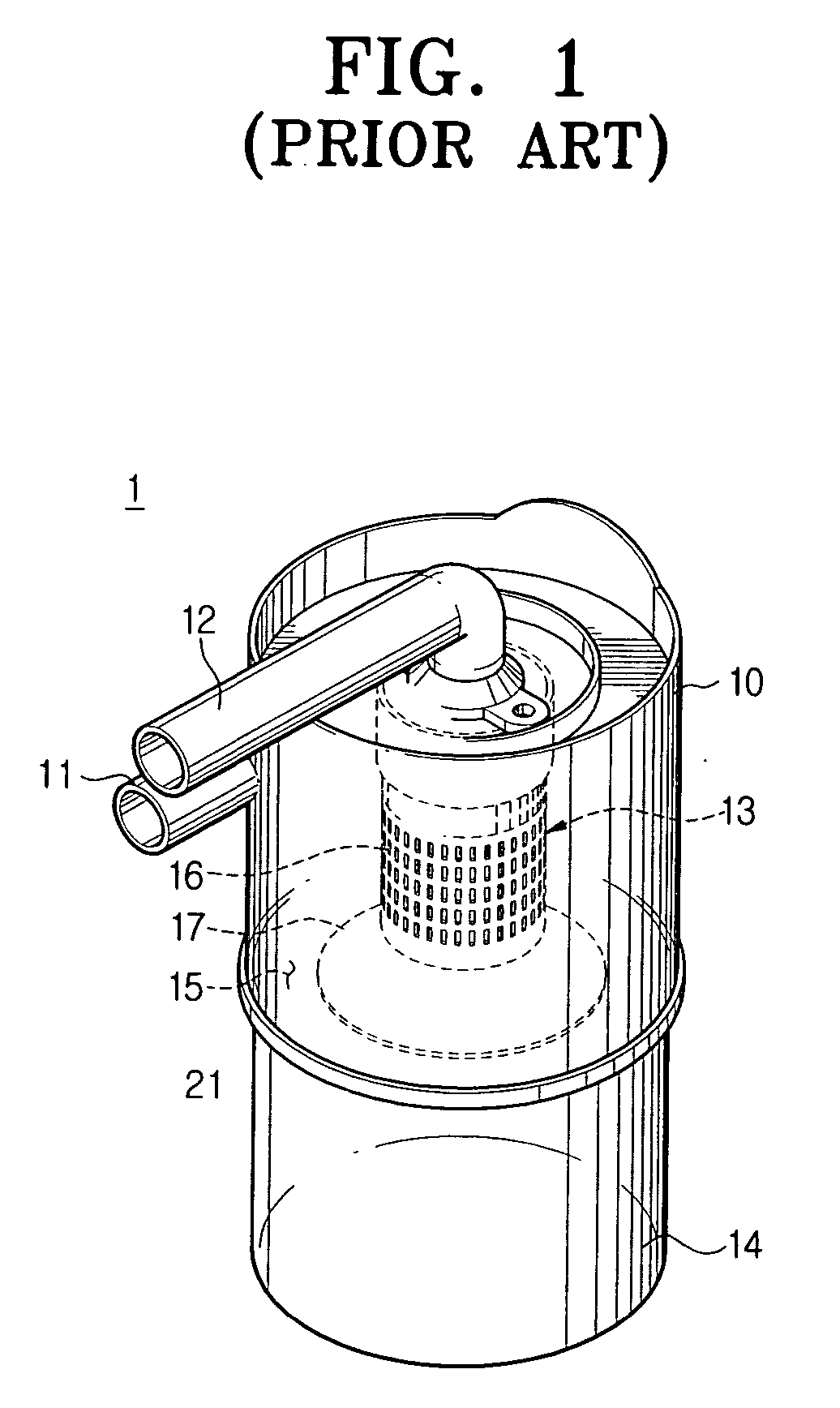

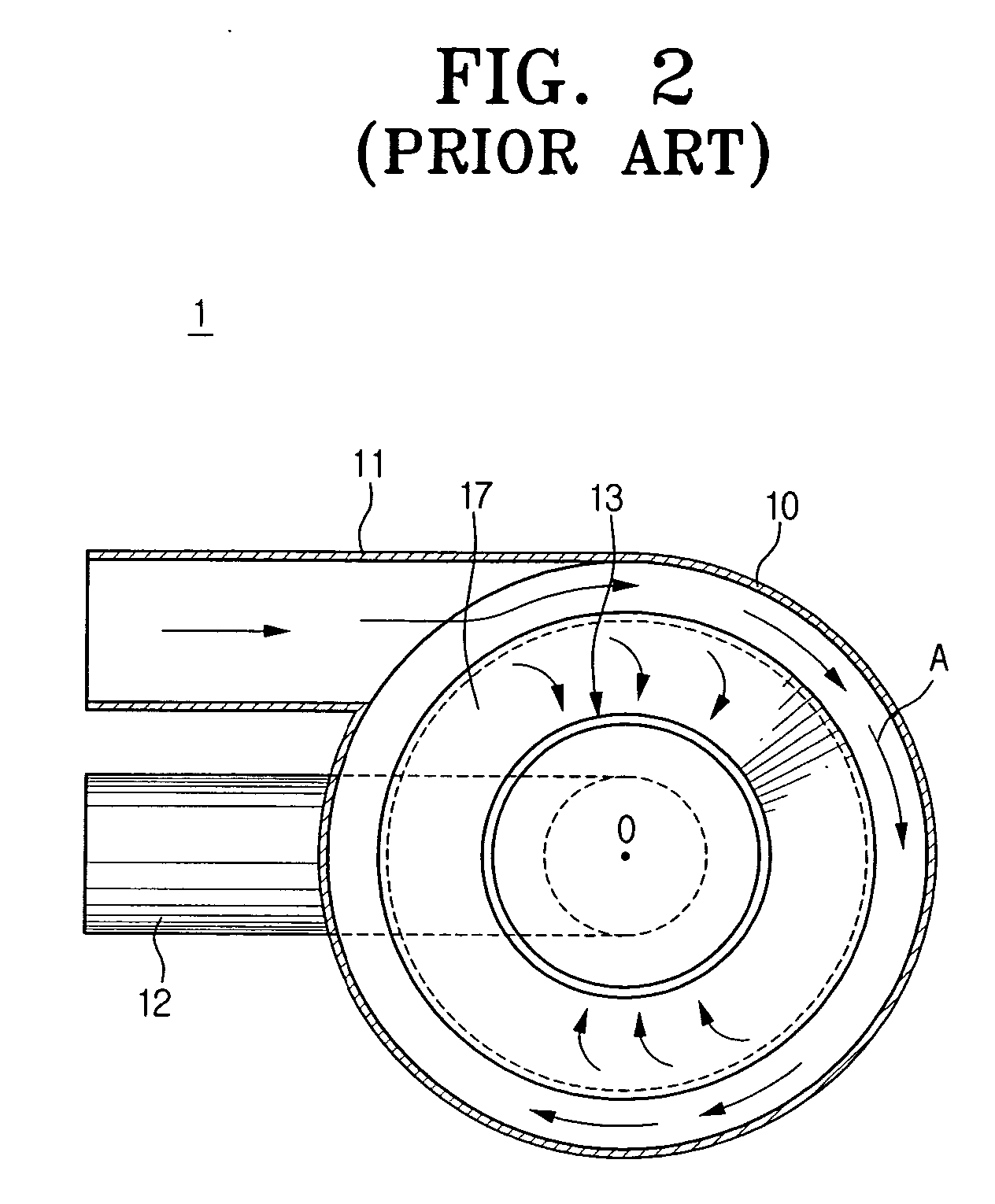

[0038] Exemplary embodiments of a grille member according to the present invention, a cyclone dust-collecting apparatus and a vacuum cleaner including such apparatus will now be described in greater detail with reference to the accompanying drawing figures.

[0039]FIG. 4 is a view schematically showing an upright vacuum cleaner 200 having a cyclone dust-collecting apparatus with a grille member according to an embodiment of the present invention.

[0040] As shown in FIG. 4, the upright vacuum cleaner 200 according to an exemplary embodiment of the present invention comprises a cleaner body 101 having vacuum suction means such as a vacuum motor installed therein, a suction brush 102 for drawing in dirt-laden air from a cleaning surface, and a cyclone dust-collecting apparatus 100 removably mounted in the cleaner body 101, for separating dirt from the intake air.

[0041] In this embodiment, the cleaner body 101 and the suction brush 102 are conventional, so detailed descriptions thereof are

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap