Construction waste vertical transportation system for super high-rise buildings

A technology for vertical transportation of construction waste, applied in the direction of buildings, building components, building structures, etc., can solve problems such as easy damage to pipelines, difficult maintenance, and unsatisfactory requirements, and achieve convenient maintenance, timely removal and transportation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

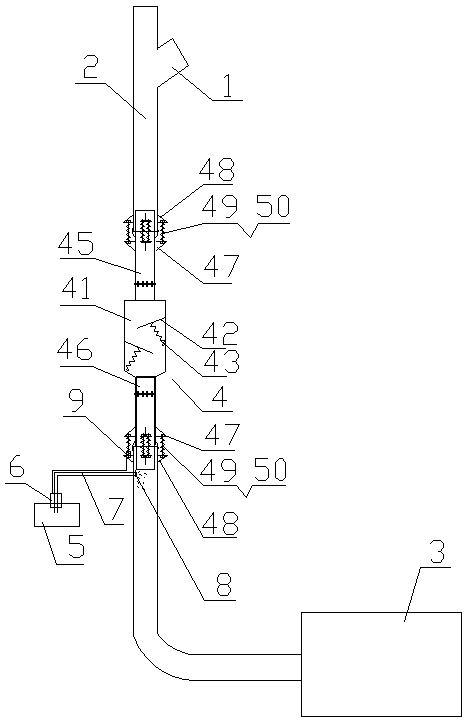

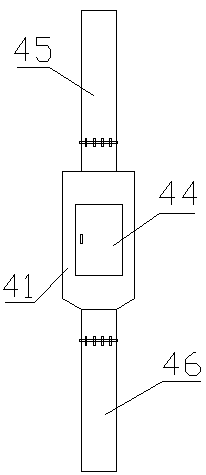

[0013] Example figure 1 As shown, the construction waste vertical transport system for super high-rise buildings of the present invention includes construction waste disposal ports 1, vertical conveying pipes 2 and construction waste recovery sealed cabins 3 on each level, and the construction waste disposal ports 1 on each level are respectively connected to the Vertical conveying pipeline 2, the end of described vertical conveying pipeline 2 is connected with described construction waste sealing recovery chamber 3, and this system also comprises buffer 4, water tank 5, water pump 6, water pipe 7 and sprinkler head 8, and described buffer 4 Including a buffer compartment 41, a buffer steel plate 42 and a buffer spring 43, the buffer compartment 41 is arranged on the vertical conveying pipeline 2, the buffer steel plate 42 is obliquely arranged on the inner wall of the buffer compartment 41, and the buffer spring 43 is arranged on the inner wall of the buffer compartment 41 Betwe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap