Trash burning chamber structure

A combustion chamber and garbage technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of large pollution, high use cost, and high input cost of manual incineration, and achieve easy popularization and use, full combustion process, and comprehensive functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

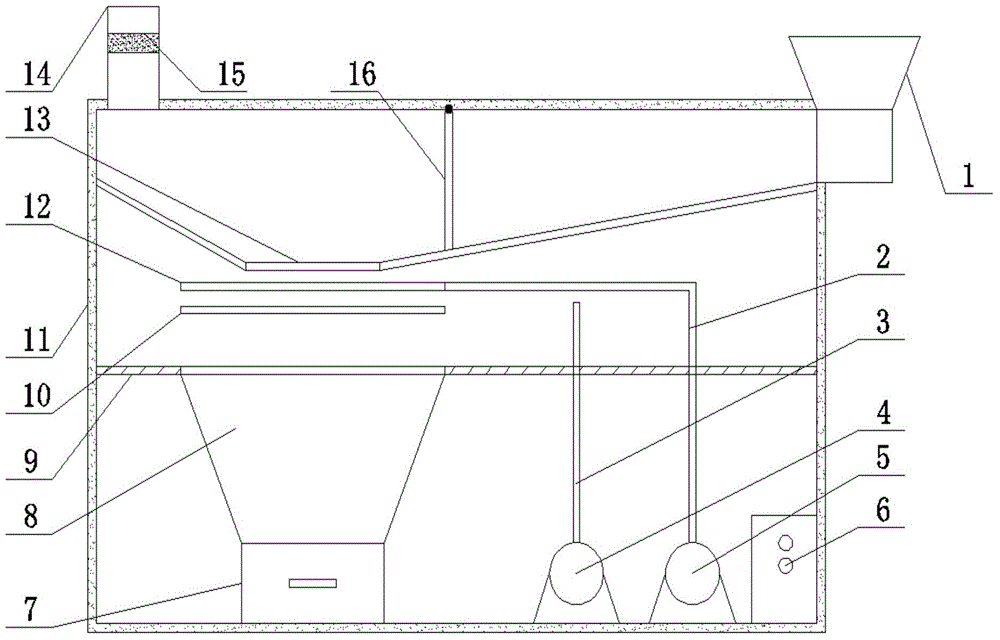

[0022] Such as figure 1 As shown, the present invention comprises the box body 11 that is provided with insulation layer, and described box body 11 side top is equipped with feed hopper 1, and the other side top end of box body 11 is equipped with chimney 14, and described box body 11 interior level Partition plate 9 is set, and partition plate 9 divides casing 11 into two cavities up and down, and the upper cavity is a combustion chamber, and a fire grate 13 for carrying garbage is horizontally provided in the upper cavity, and the opposite ends of the fire grate 13 are provided with There is an upward inclined surface, one inclined surface of the fire grate 13 extends to the inner surface of the box body 11, and the other inclined surface of the fire grate 13 extends to the bottom of the feed hopper 1, and the inner top surface of the box body 11 is close to the feed hopper. 1 A sealing flap 16 is installed between the slopes of the grate 13 on the bottom side, and the sealing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap