Dual-layer mechanical grate type garbage gasifying incinerator and dual-boiler power generation system thereof

A technology of mechanical grate and power generation system, which is applied in the direction of mechanical equipment, machine/engine, incinerator, etc. It can solve the problem that the heat energy recovery system and flue gas treatment system are greatly affected, and the continuous gasification incineration treatment and ash cleaning of garbage cannot be realized. Overhaul and maintenance period is short and other problems, to achieve the effect of improving energy conversion efficiency, improving heat exchange efficiency, and ensuring thermal ignition loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

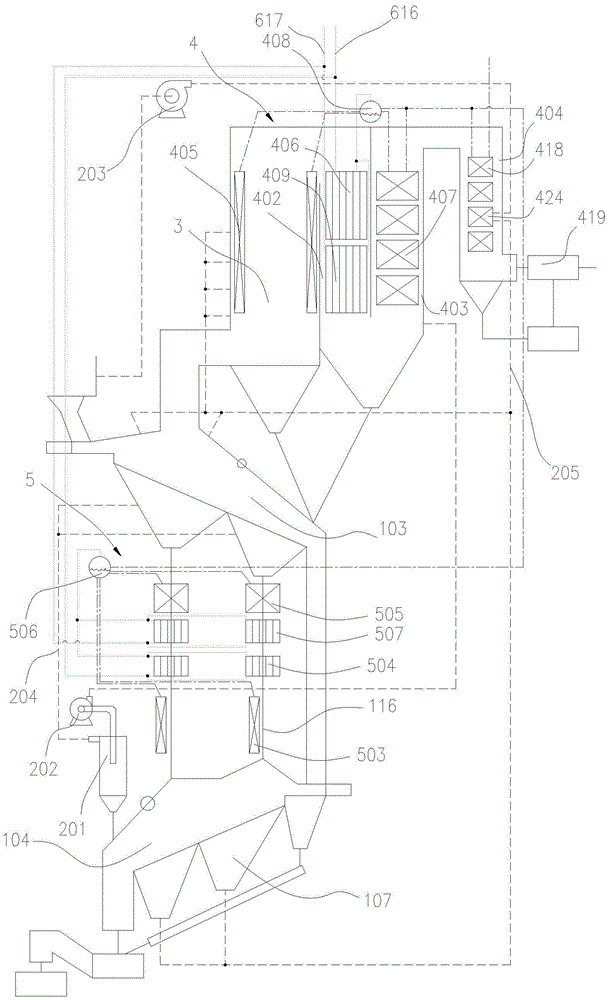

[0051] See Figure 1 to Figure 6 , Is a preferred embodiment of a double-layer mechanical grate type waste gasification incinerator and its double boiler power generation system, including a double-layer waste gasification incinerator 1, a boiler system, a circulating air supply system, and a power generation system.

[0052] See Image 6 , Including a double-layer garbage gasification incinerator 1, the double-layer garbage gasification incinerator 1 includes a grate 101 on which a feeding bin 102 and a gasification furnace 103 are sequentially arranged along the feeding direction. The furnace frame 101 is also provided with an incinerator 104. The incinerator 104 is located directly below the gasification furnace 103. The feeding direction of the incineration furnace 104 is opposite to that of the gasification furnace 103. 103 is mainly to gasify the charcoal part of the garbage and discharge combustible gasification flue gas and garbage residue. The incinerator 104 mainly performs

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap