Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Treatment unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aerobic treatment unit (ATU) consists of several processes that function together to provide a high quality effluent. These are gross solids (trash) removal, aeration, clarification, and sludge return.

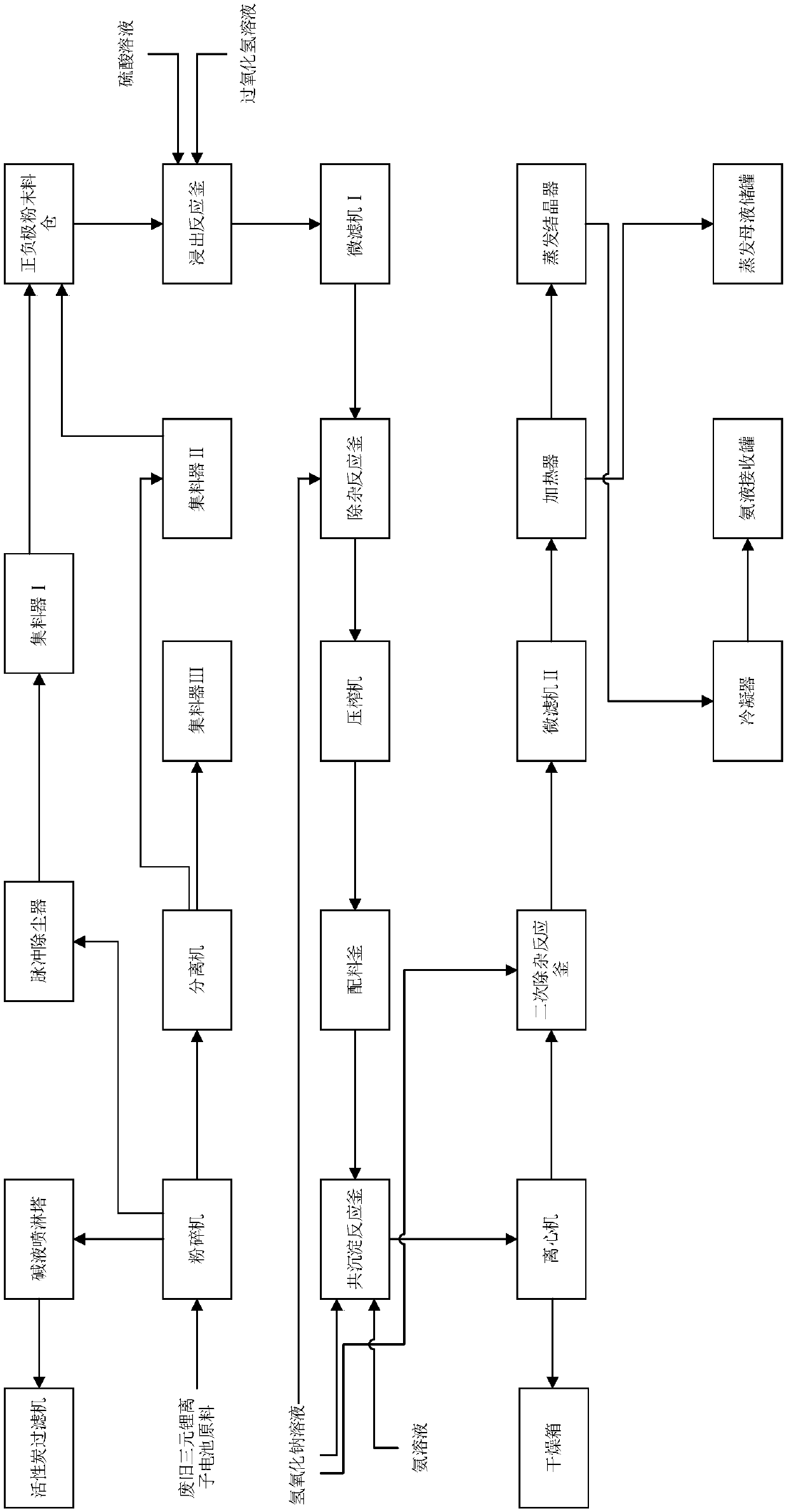

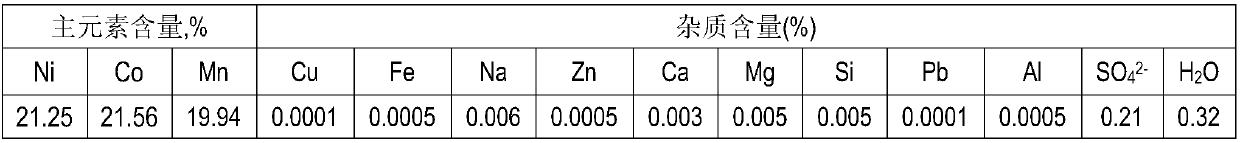

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

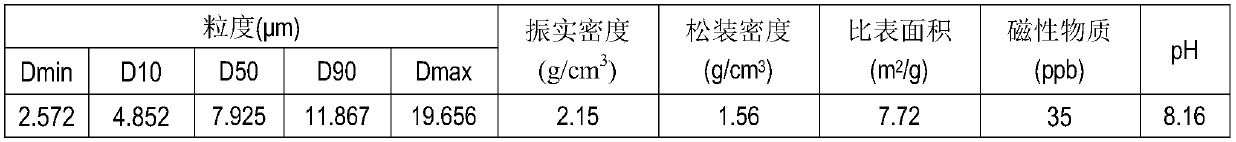

Discharge treatment system for produced water of polymer flooding oilfield

ActiveCN103663716AEasy to handleImprove adaptabilityBiological water/sewage treatmentActivated sludgeSulfate-reducing bacteria

Owner:CHINA PETROLEUM & CHEM CORP +1

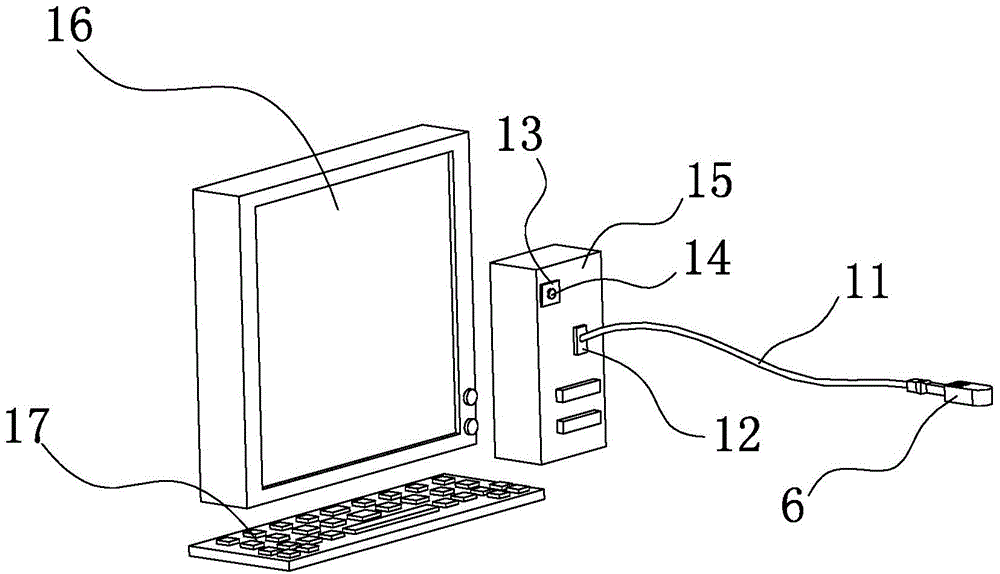

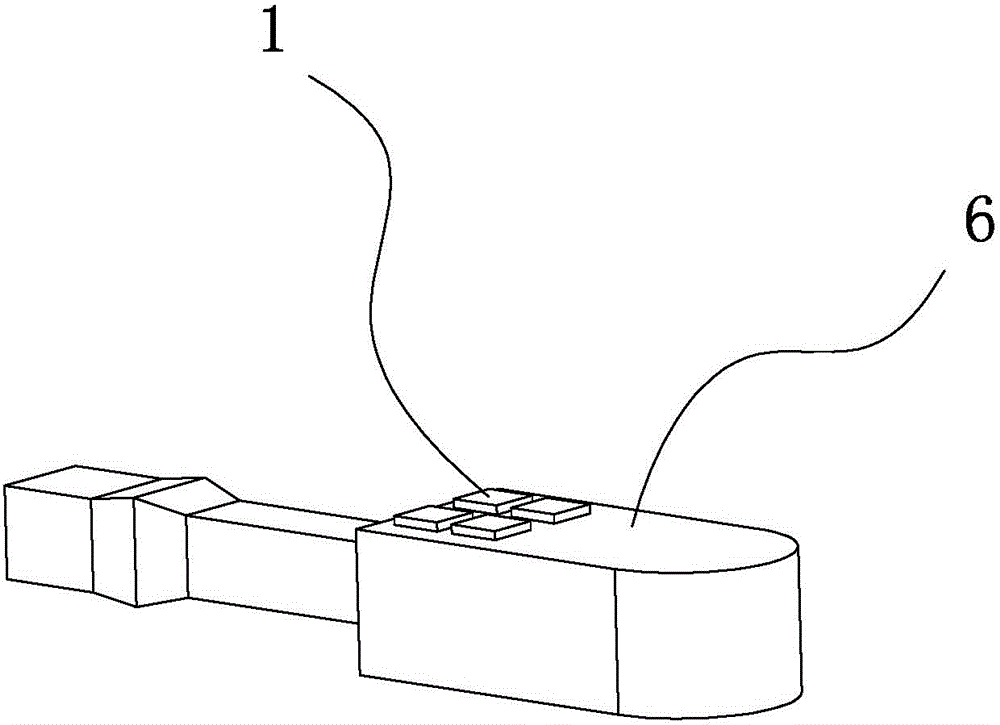

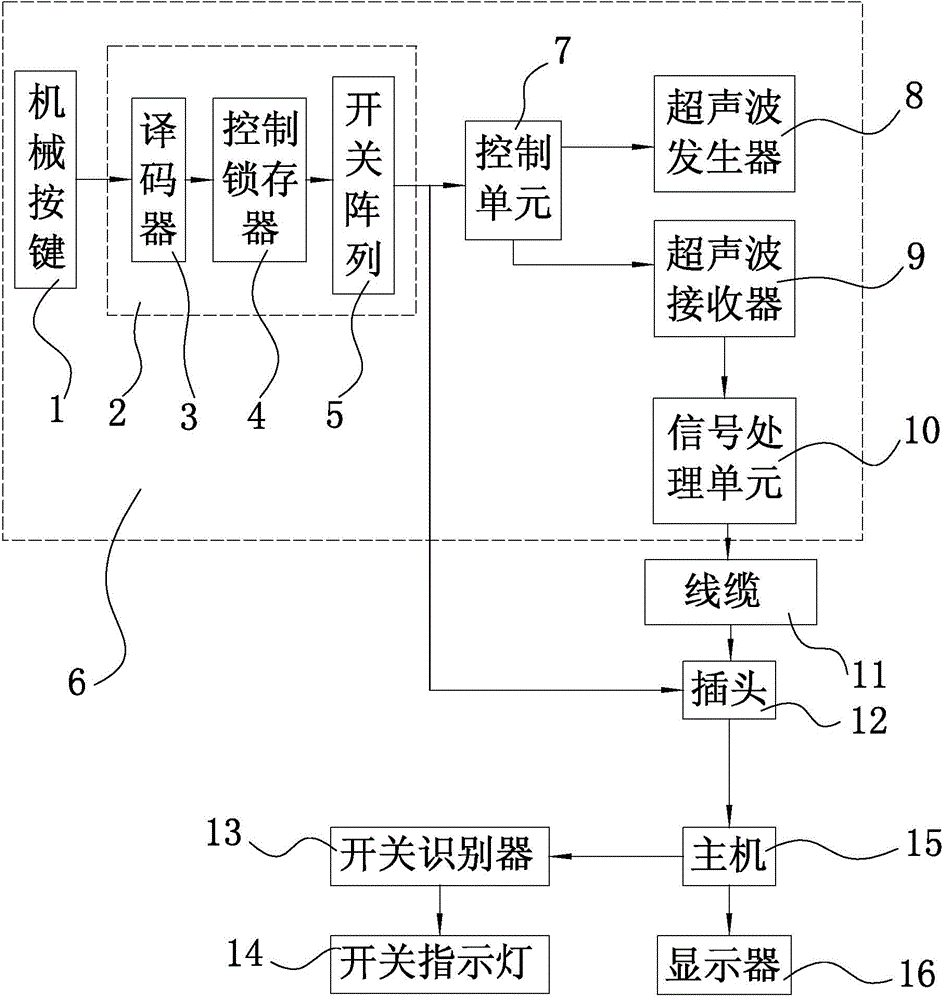

Mechanical button type integrated B-ultrasonic detecting system

InactiveCN104434180AReduce the numberAvoid mixingInfrasonic diagnosticsSonic diagnosticsDisplay deviceEngineering

Owner:SUZHOU BIANFENG ELECTRONICS TECH

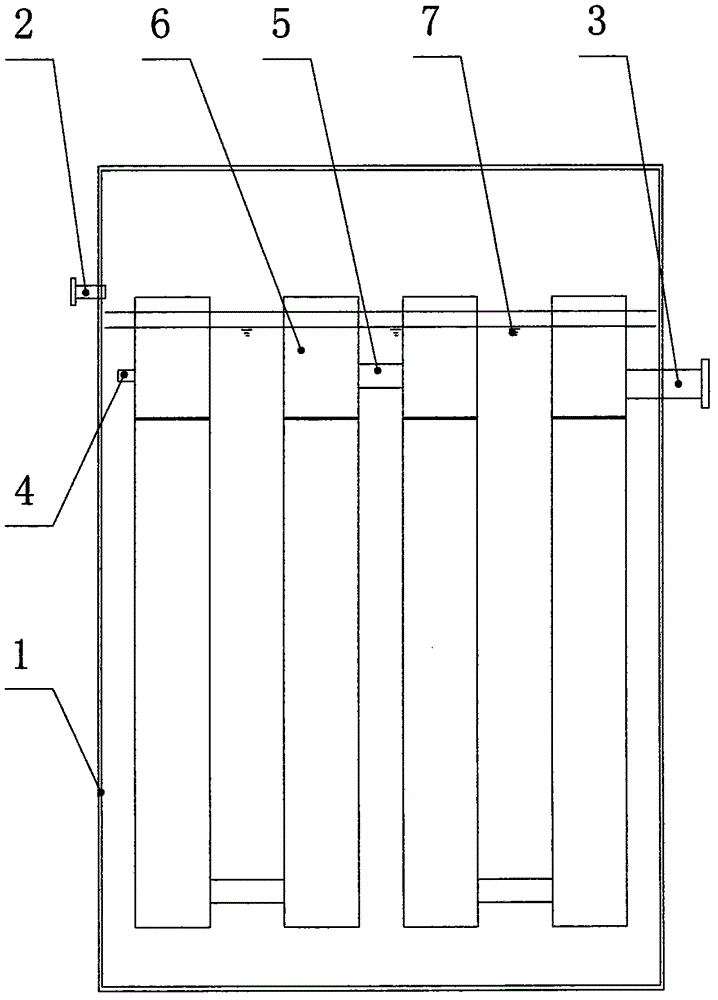

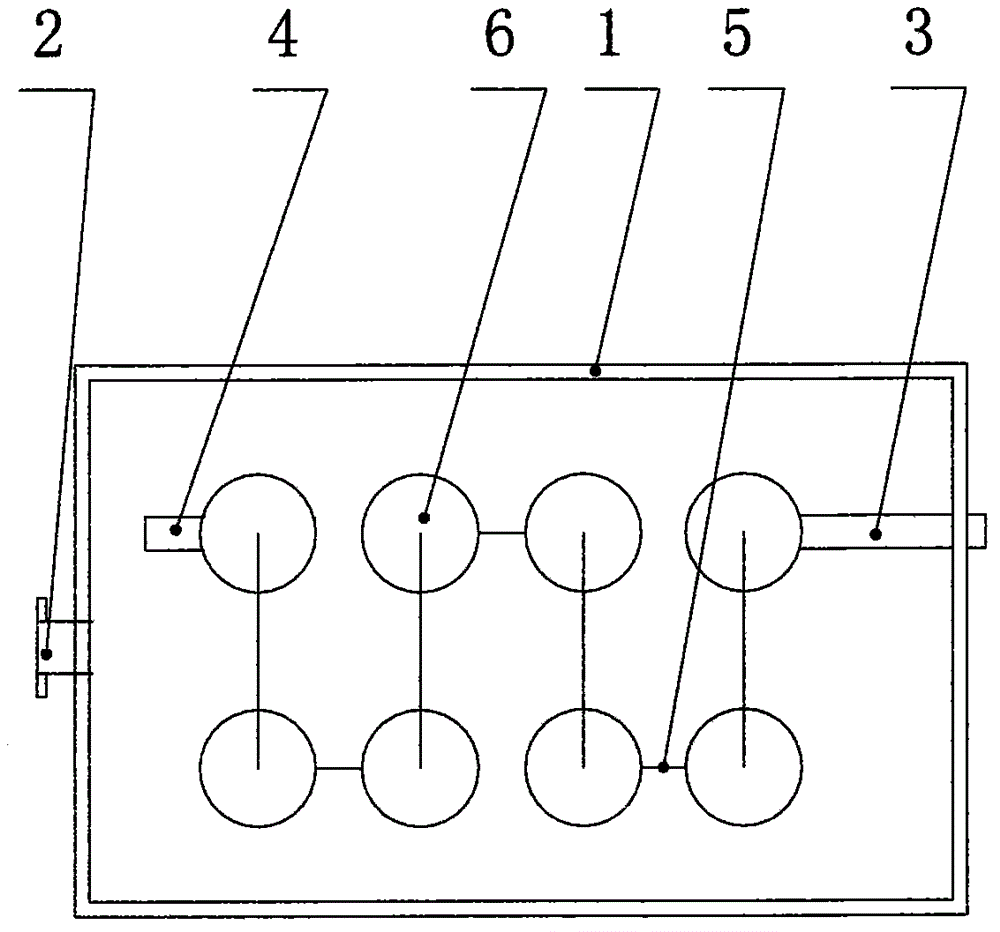

Biochemical tubular reactor for water treatment

InactiveCN104961224ASolve concentrationSolve microorganismsBiological water/sewage treatmentControllabilityWater treatment

Owner:BEIJING NEWATT ENVIRONMENTAL ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap