Device for disposing leather sludge and waste by using cement kiln and process method of device

A cement kiln and waste technology, applied in the field of leather waste treatment, can solve the problems of secondary environmental pollution, high treatment cost, inability to reduce odor and odor, and achieve the effects of avoiding pollution, low treatment cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

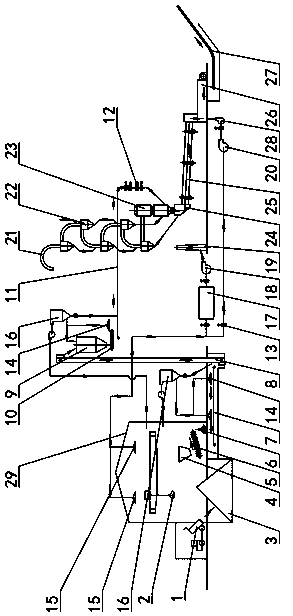

[0040] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0041]A device for disposing of leather sludge and waste using a cement kiln, including a storage 29, a feeding device, a preheater 22, a decomposition furnace 23 and a cement kiln 25, and the outlet of the storage 29 passes through the feeding device and the decomposition furnace 23 The feed port of the calciner 23 is connected with the feed port of the preheater 22, and the feed port of the preheater 22 is connected with the feed port of the cement kiln 25, and the cement kiln 25 and the decomposition The air outlet of furnace 23 is all connected with the air inlet of preheater 22, and the air outlet of preheater 22 is connected with dust collector, and storage house 29 is also connected with pumping negative pressure device, and the air outlet of pumping negative pressure device is connected with cement kiln 25 con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap