Environment-friendly treating device and process for concentrated waste liquor obtained after evaporation of pesticide and resin chemicals

A technology of concentrated waste liquid and environmental protection treatment, applied in the direction of incinerator, combustion type, alkali metal chloride, etc., to achieve the effect of protection discharge, good separation effect and zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

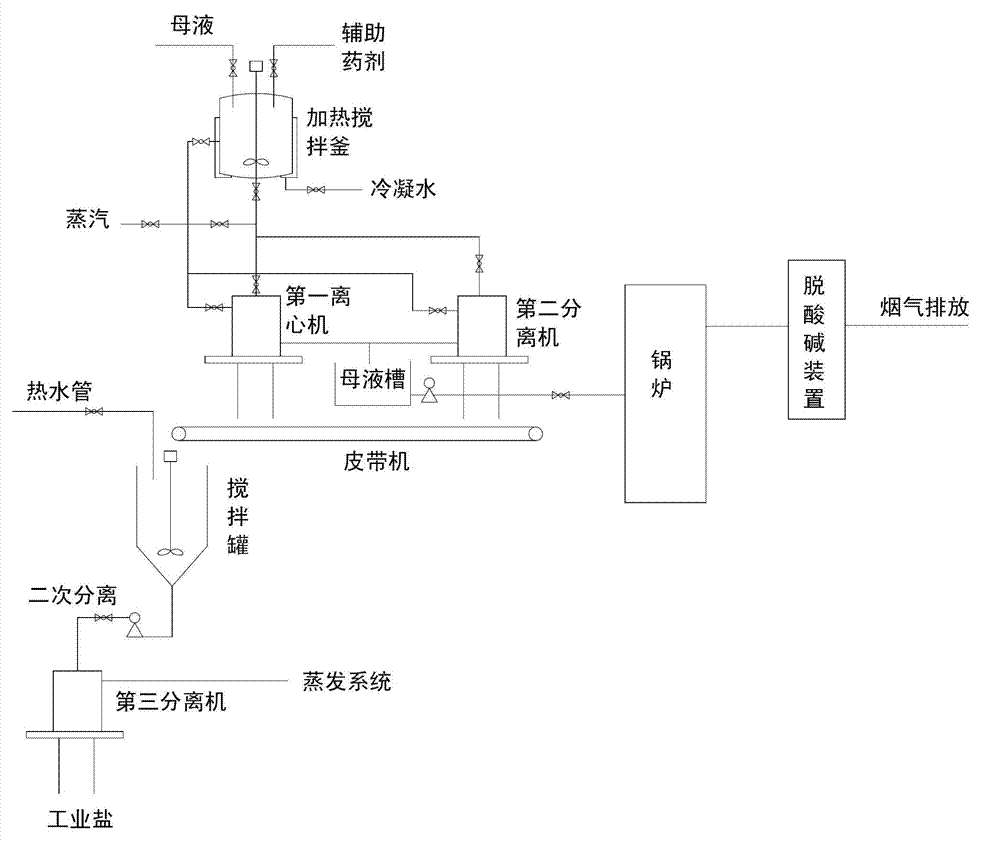

[0022] Take the specific operation process of separating glyphosate mother liquor as an example to illustrate;

[0023] Such as figure 1 As shown, an environmental protection treatment device for concentrated waste liquid after evaporation of pesticides and resin chemicals, including a heating and stirring tank, the heating and stirring tank is connected with a first centrifuge and a second centrifuge through a pipeline, and the first centrifuge and the second centrifuge The liquid outlet is connected to the mother liquor tank, the solid matter outlets of the first centrifuge and the second centrifuge are connected to the belt conveyor, the discharge end of the belt conveyor is connected to the stirring tank, and the outlet of the stirring tank is connected to the third centrifuge through a pipeline , the liquid outlet of the third centrifuge is connected to the evaporation circulation system, the mother liquid tank is connected to the boiler, the exhaust port of the boiler is co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap