Self-circulating type garbage disposal equipment

A garbage disposal equipment and self-circulating technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve problems such as waste of resources, and achieve the effect of reducing total cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the technical solution of the present invention will be described in detail through specific examples.

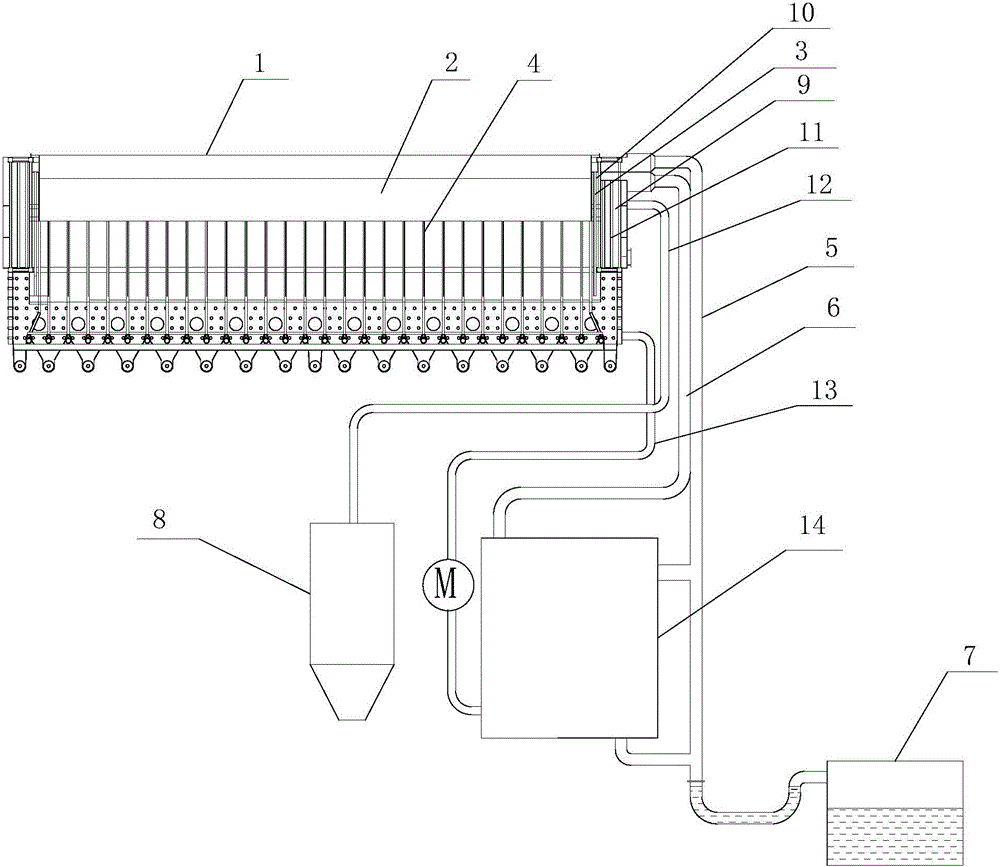

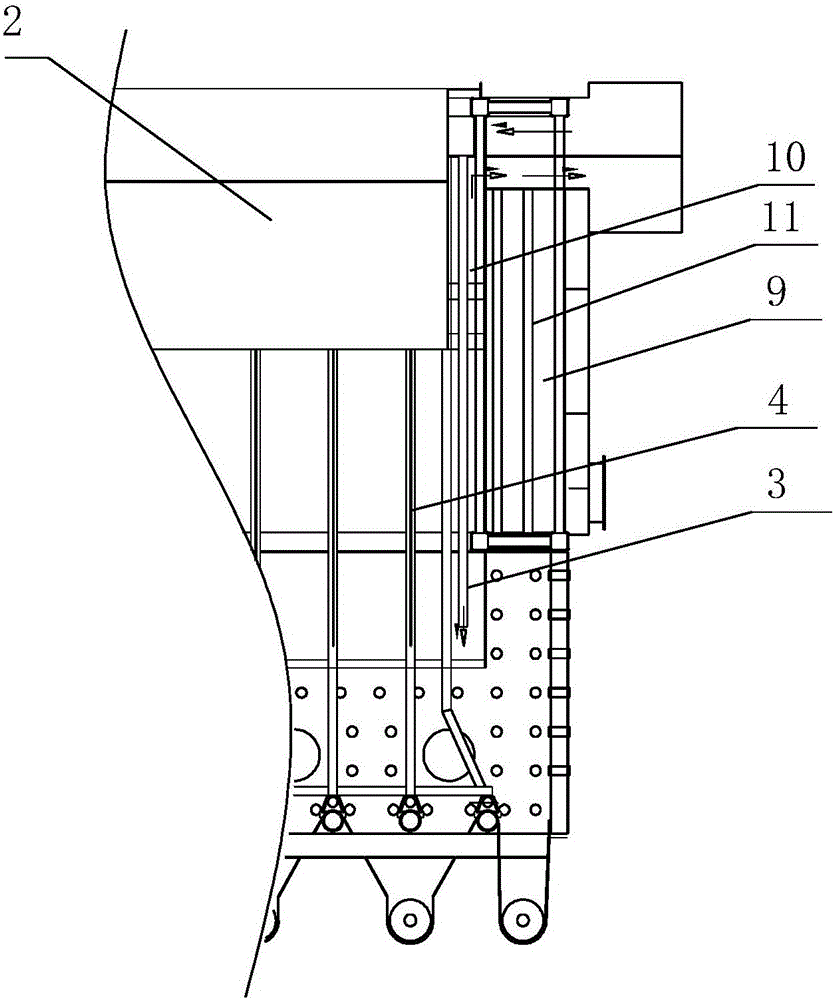

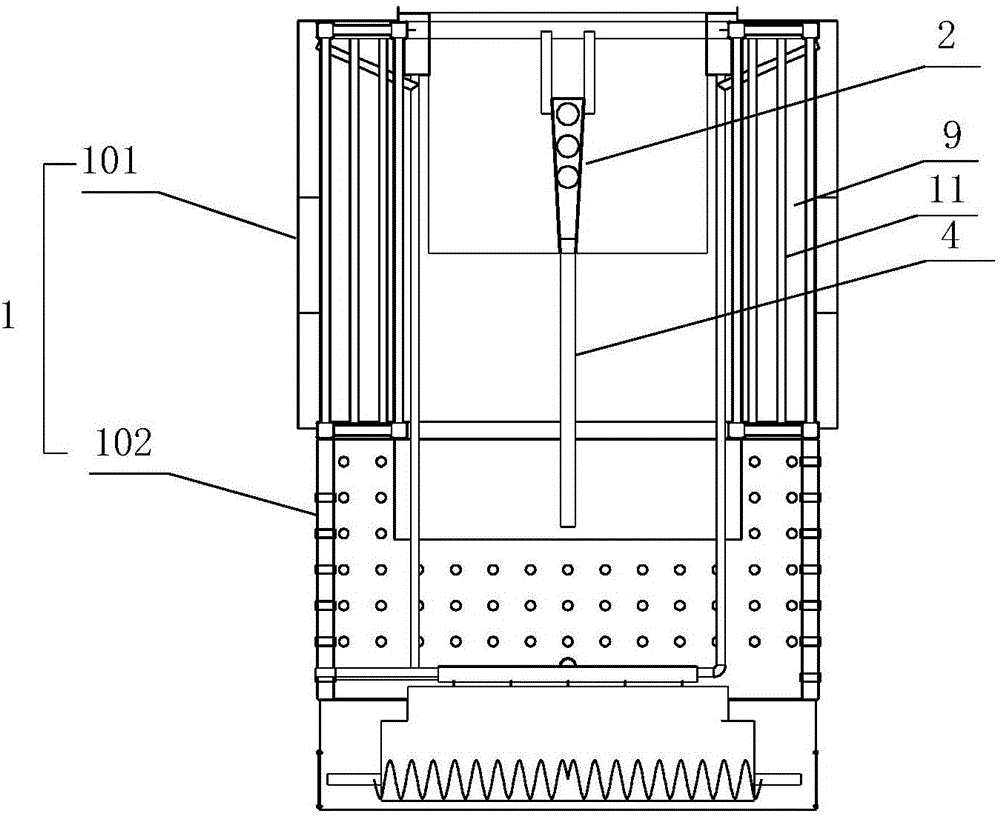

[0035] Such as Figure 1-3 as shown, figure 1 It is a schematic structural diagram of a self-circulating garbage disposal device proposed by the present invention; figure 2 It is a partially enlarged view of a self-circulating garbage disposal device proposed by the present invention; image 3 It is a side view of a self-circulating garbage disposal device proposed by the present invention.

[0036] refer to Figure 1-3 , a self-circulating garbage disposal device proposed by the embodiment of the present invention, comprising: a gasifier 1, an air intake device 2, an internal circulation pipe 3, a first air guide pipe 4, a second air guide pipe 5, and a third air guide pipe 6 , a first induced draft fan (not shown in the figure), a second induced draft fan (not shown in the figure), a water cooling device 14, a water tank 7 and an exhaust gas purification d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap