Improved cobalt-based catalyst and preparing method and application thereof

A cobalt-based catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, combustion methods, etc., can solve the problems of poor activity and stability, catalyst agglomeration, low specific surface area, etc., and achieve good stability and activity High and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

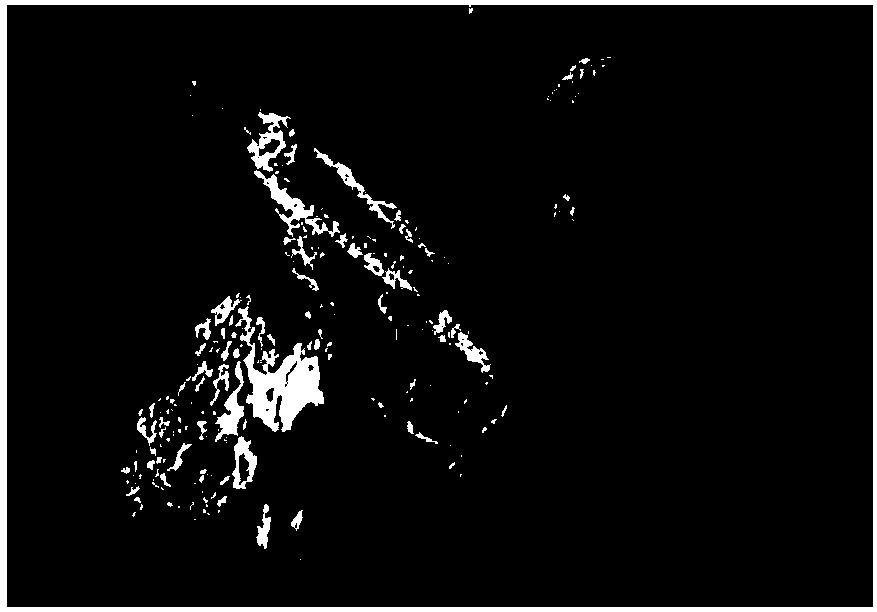

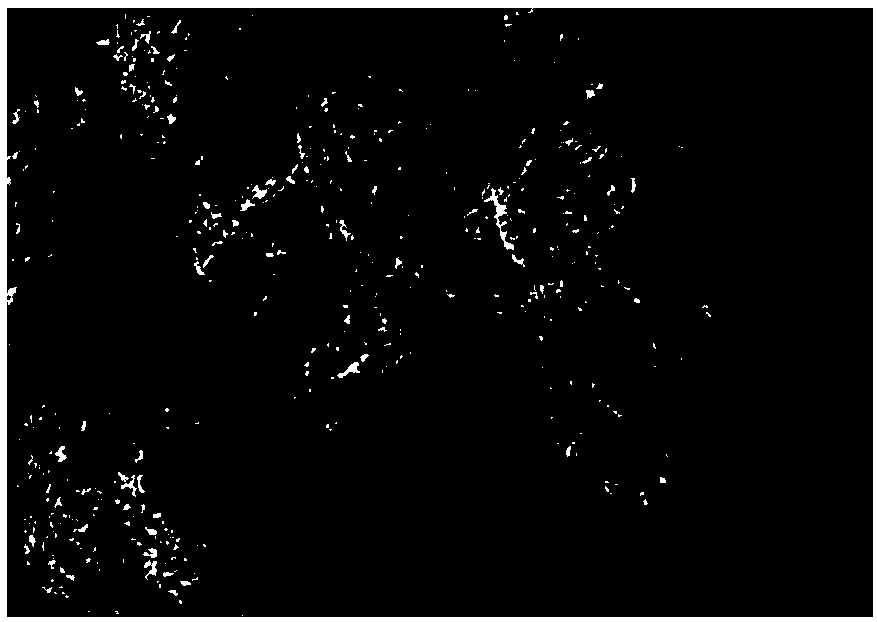

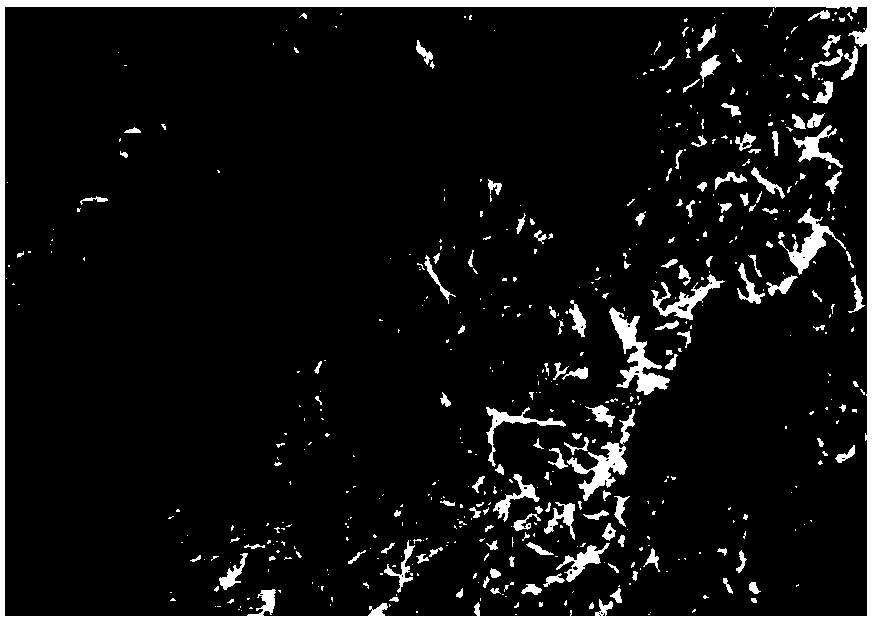

Image

Examples

Embodiment 1

[0031] 6 g of glucose was dissolved in 90 mL of deionized water, and the resulting solution was ultrasonically oscillated for 30 min until the glucose was uniformly dispersed in the solution. Pour the glucose solution into a 100mL polytetrafluoroethylene liner, and place it in a reaction kettle at 170°C for 10h. After cooling to room temperature, filter with suction, alternately wash three times with deionized water and absolute ethanol, and finally vacuum-dry at 80°C for 6 hours to obtain carbon sphere powder.

[0032] Soluble cobalt salt and lanthanum salt are used as precursors, and the molar ratio of La:Co is 0:1. Add an appropriate amount of deionized water to make the solution metal ion concentration equal to 0.12mol / L, and stir to obtain a transparent mixed solution.

[0033] Add 0.05 g of carbon spheres to the resulting solution, and ultrasonically oscillate for 1 hour to disperse the carbon sphere powder evenly in the solution, then slowly add ammonia solution dropwise

Embodiment 2

[0037] This example is an example of the preparation method of the modified cobalt-based catalyst of the present invention.

[0038] 6 g of glucose was dissolved in 90 mL of deionized water, and the resulting solution was ultrasonically oscillated for 30 min until the glucose was uniformly dispersed in the solution. Pour the glucose solution into a 100mL polytetrafluoroethylene liner, and place it in a reaction kettle at 170°C for 10h. After cooling to room temperature, filter with suction, alternately wash three times with deionized water and absolute ethanol, and finally vacuum-dry at 80°C for 6 hours to obtain carbon sphere powder.

[0039] Soluble cobalt salt and lanthanum salt are used as precursors, and the molar ratio of La:Co is 1:10. Add an appropriate amount of deionized water to make the solution metal ion concentration equal to 0.12mol / L, and stir to obtain a transparent mixed solution.

[0040]Add 0.05 g of carbon spheres to the resulting solution, and ultrasonica

Embodiment 3

[0044] This example is an example of the preparation method of the modified cobalt-based catalyst of the present invention.

[0045] 6 g of glucose was dissolved in 90 mL of deionized water, and the resulting solution was ultrasonically oscillated for 30 min until the glucose was uniformly dispersed in the solution. Pour the glucose solution into a 100mL polytetrafluoroethylene liner, and place it in a reaction kettle at 170°C for 10h. After cooling to room temperature, filter with suction, alternately wash three times with deionized water and absolute ethanol, and finally vacuum-dry at 80°C for 6 hours to obtain carbon sphere powder.

[0046] Soluble cobalt salt and lanthanum salt are used as precursors, and the molar ratio of La:Co is 1:4. Add an appropriate amount of deionized water to make the solution metal ion concentration equal to 0.12mol / L, and stir to obtain a transparent mixed solution.

[0047] Add 0.05 g of carbon spheres to the resulting solution, and ultrasonica

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap