Preparation method of SSZ-13 molecular sieve for MTO catalytic reaction

A catalytic reaction and molecular sieve technology, applied in the field of preparation of SSZ-13 molecular sieve, can solve the problems of easy clogging of copper and difficulty in preparing copper content, and achieve the effects of improving relative crystallinity, reducing preparation cost and reducing synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

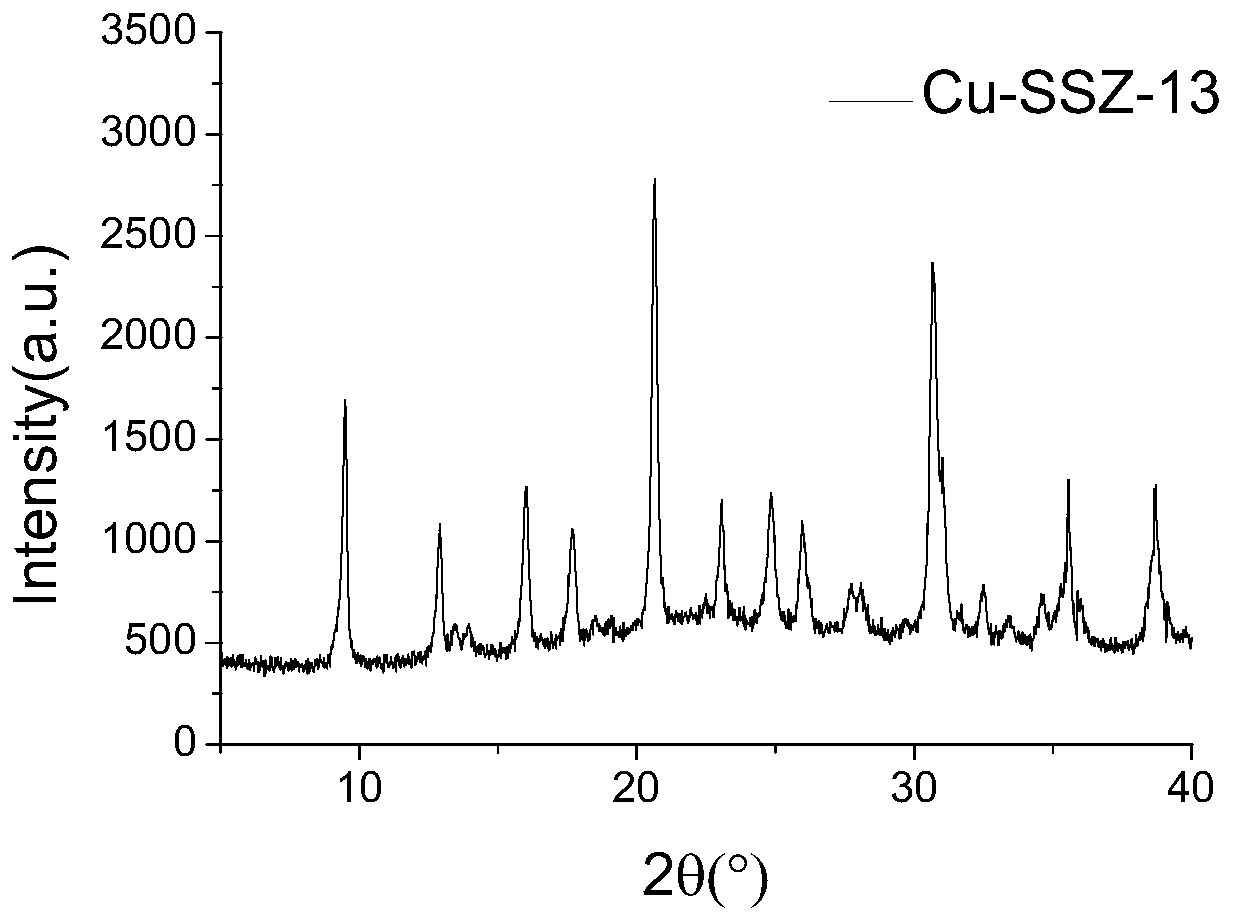

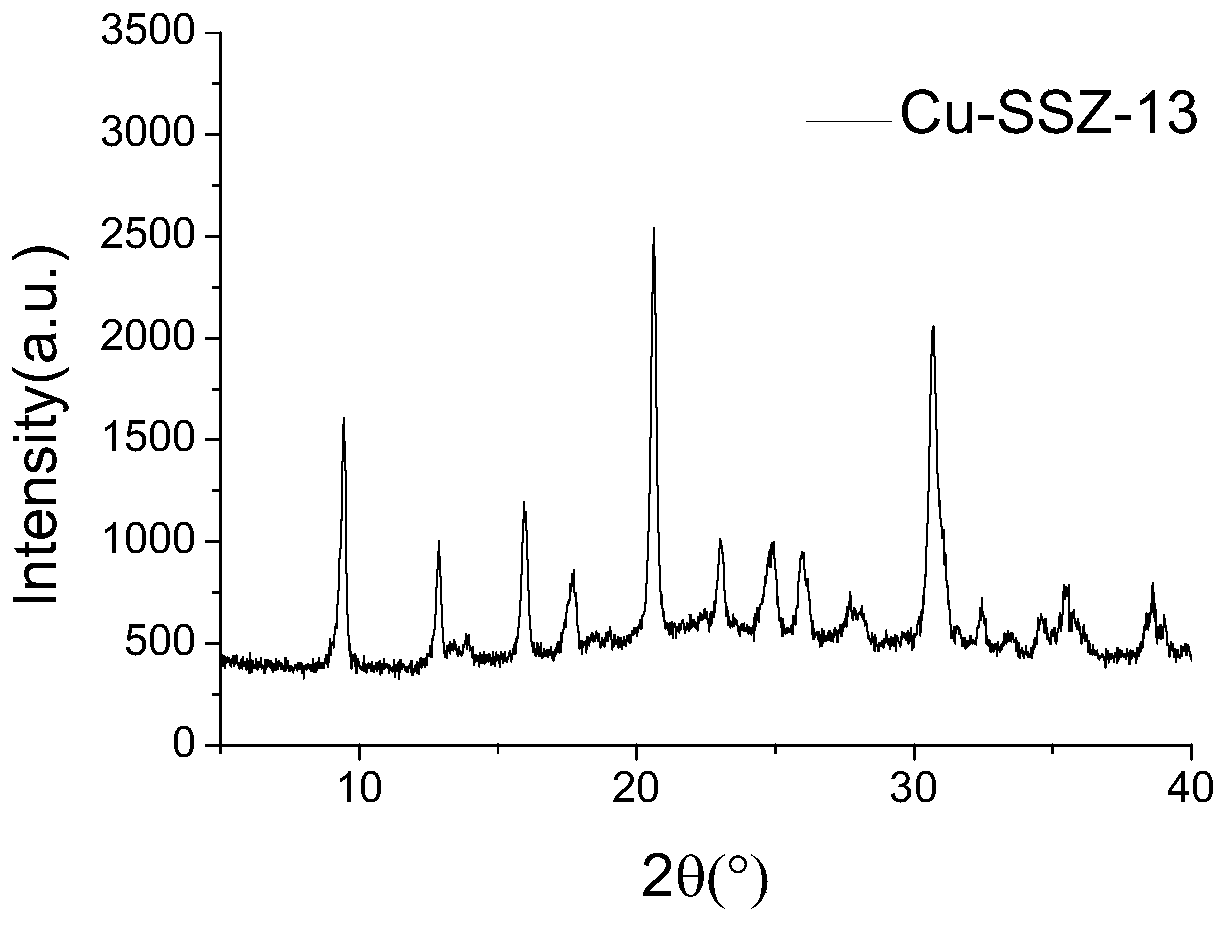

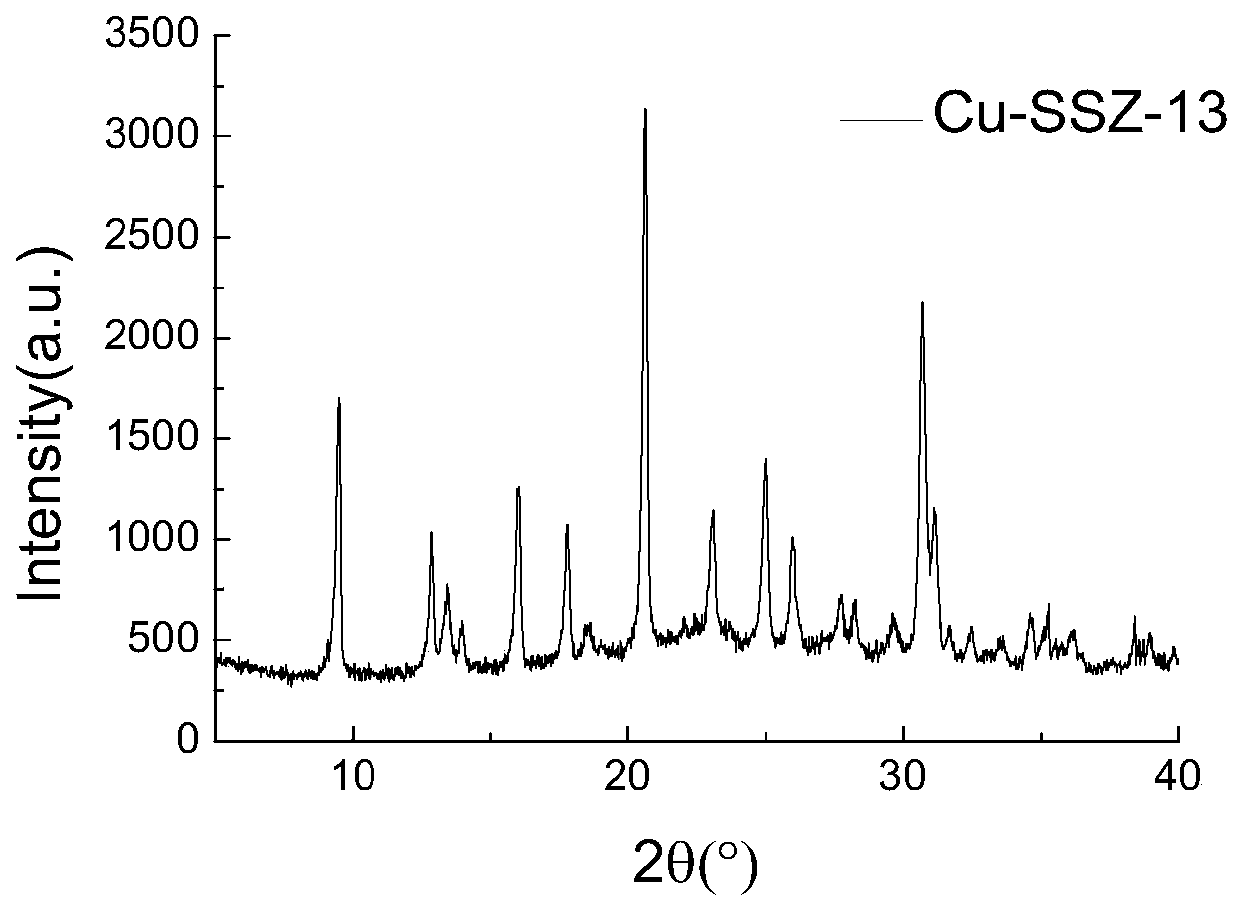

Image

Examples

preparation example Construction

[0037] A kind of preparation method for the SSZ-13 molecular sieve of MTO catalytic reaction, comprises the following steps:

[0038] (1) Preparation of Cu-SSZ-13 molecular sieve: the aluminum source, silicon source, sodium source, water and copper amine complex according to 1.0Al 2 o 3 :10~35SiO2 2 :3.0~5.0Na 2 O:200~300H 2 O: 2.0~4.0Cu-TEPA molar ratio mixed at room temperature, stirred with a stirring paddle for 30min, put into a polytetrafluoroethylene-lined steel reaction kettle, reacted at 130℃~175℃ for 96h~144h, reacted After completion, the product was washed with deionized water and dried at 100°C for 12 hours to obtain Cu-SSZ-13 molecular sieve (S1). The silicon source used in this step was water glass, silica sol, silica gel, amorphous SiO 2 Powder, Si(OCH 3 ) 4 and Si(OC 2 h 5 ) 4 One or several mixtures of them, the aluminum source is sodium metaaluminate, pseudoboehmite, amorphous aluminum hydroxide powder and aluminum isopropoxide, and the sodium source is

Embodiment 1

[0048] Preparation of SSZ-13 molecular sieve with copper amine complex as template

[0049] The preparation of Cu-SSZ-13 molecular sieve: Sodium metaaluminate, water glass, sodium hydroxide, deionized water and copper ammonium complex are according to n(Al 2 o 3 ):n(SiO 2 ):n(Na 2 O):n(H 2 The molar ratio of O):n(Cu-TEPA) is 1:10:3.0:200:2.0, mixed at room temperature, and stirred with a stirring paddle for 30min. Put it into a polytetrafluoroethylene-lined steel reactor and react at 130°C for 96h. After the reaction was completed, the product was washed with deionized water and dried at 100° C. for 12 hours to obtain Cu-SSZ-13 molecular sieve (S1).

[0050] Removal of Cu: Add 2 g of the synthesized S1 sample into 50 mL of ammonium nitrate solution with a concentration of 1 mol / L, ion exchange for 4 h in a water bath at 80 °C, wash, and dry at a constant temperature of 100 °C for 2 h, repeating 3 times. A molecular sieve sample (S2) is obtained.

[0051] Secondary crysta

Embodiment 2

[0053] Preparation of SSZ-13 molecular sieve with copper amine complex as template

[0054] Preparation of Cu-SSZ-13 molecular sieve: Pseudoboehmite (CP), Si(OCH 3 ) 4 (AR), sodium oxide (AR), deionized water and copper ammonium complex according to n(Al 2 o 3 ):n(SiO 2 ):n(Na 2 O):n(H 2 The molar ratio of O):n(Cu-TEPA) is 1:20:3.5:220:2.5. Mix at room temperature and stir with a stirring paddle for 30min. Put it into a polytetrafluoroethylene-lined steel reactor and react at 140°C for 108h. After the reaction was completed, the product was washed with deionized water and dried at 100° C. for 12 hours to obtain Cu-SSZ-13 molecular sieve (S1).

[0055]Removal of Cu: Add 2 g of the synthesized S1 sample into 50 mL of ammonium chloride solution with a concentration of 1.2 mol / L, ion exchange for 6 h in a water bath at 80 °C, wash, and dry at a constant temperature of 100 °C for 2 h, repeating 3 times. A molecular sieve sample (S2) is obtained.

[0056] Secondary crystalli

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap