Process for producing low-molecular olefins by pyrolysis of hydrocarbons

a technology of hydrocarbon pyrolysis and hydrocarbons, which is applied in the field of petrochemical industry, can solve the problems of increasing the yield of less valuable acetylene, overheating the cracking tube, and reducing the productivity of the pyrolysis plant, and achieves the effect of reducing the energy consumption of process conducting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

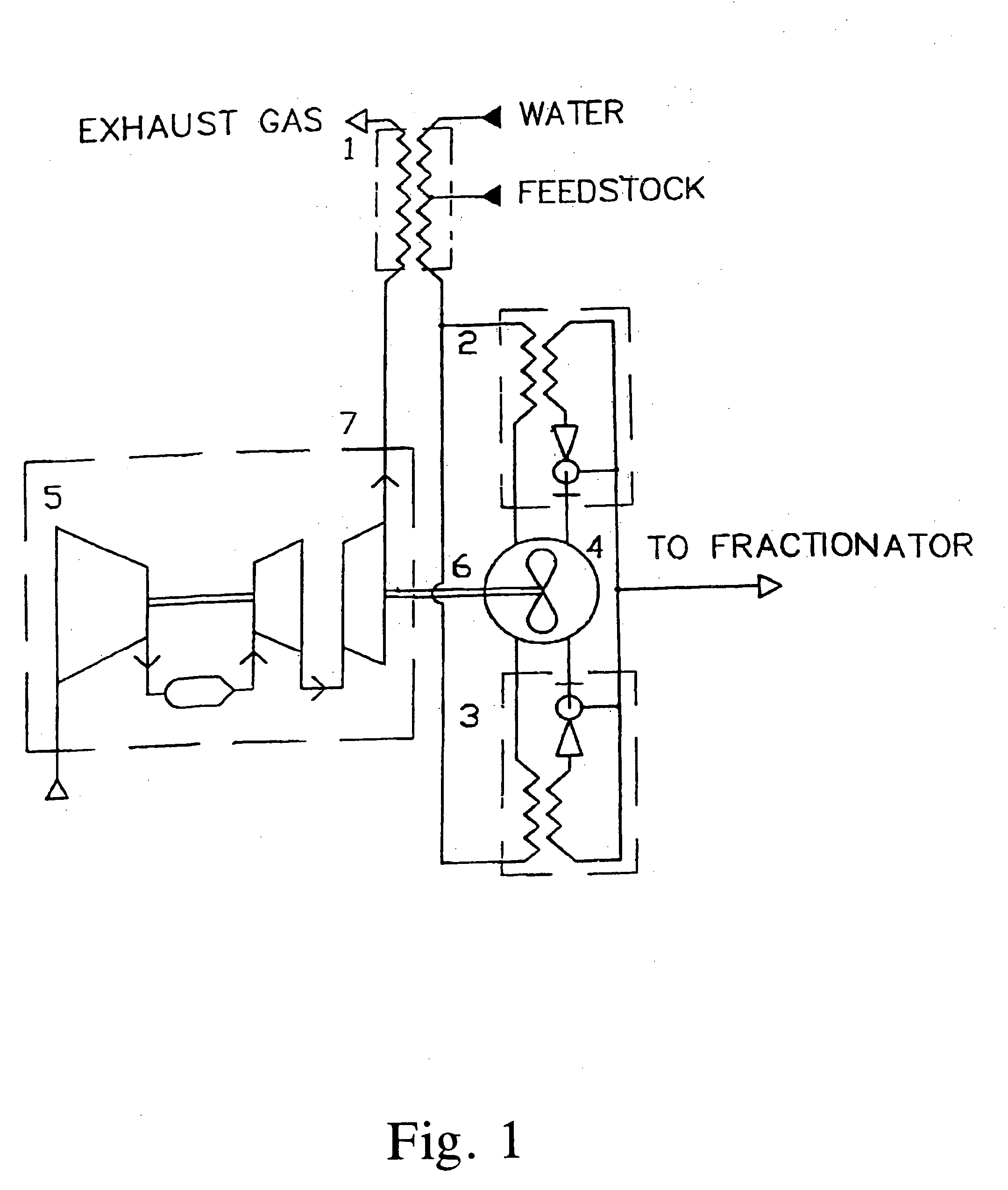

[0054] The installation (FIG. 1) for realization of the process includes preheater 1, apparatuses 2 and 3 for quenching of product stream, reactor 4, gas-turbine engine 5 connected with reactor 4 by shaft 6, and with the preheater 1 by exhaust pipe 7.

[0055] Preheating a feedstock and steam-diluent in the first stage is carried out in the preheater 1. The hydrocarbon feed form outside source (not shown in drawings) is conveyed by pressure into the preheater 1 configured as a shell-tube heat exchanger. The exhaust gas from the gas-turbine engine 5 is discharged into the intertubular space of this heat exchanger. From an outside source (not shown in drawings) water is conveyed by pressure into the preheater where the water it is evaporated, and resulting steam-diluent is mixed with the hydrocarbon feed.

[0056] Preheating a feedstock and steam-diluent in the second stage is carried out in the apparatuses 2 and 3 for quenching of product stream by utilization of heat of product stream leav

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap