A retaining force adjustable parallel permanent magnetic actuator

A technology of permanent magnet operation and holding force, which is applied in the direction of electromagnetic relay, detailed information of electromagnetic relay, power device inside the switch, etc. To achieve the effect of saving energy consumption, reducing capacity and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

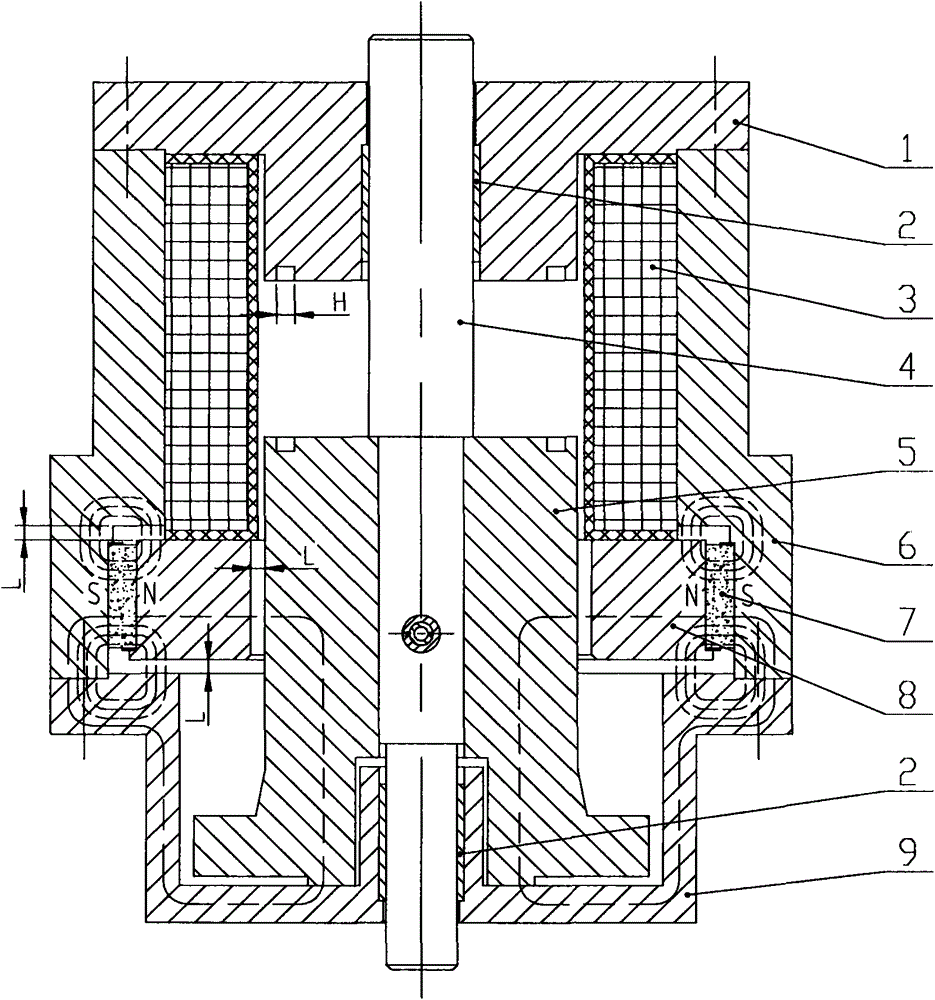

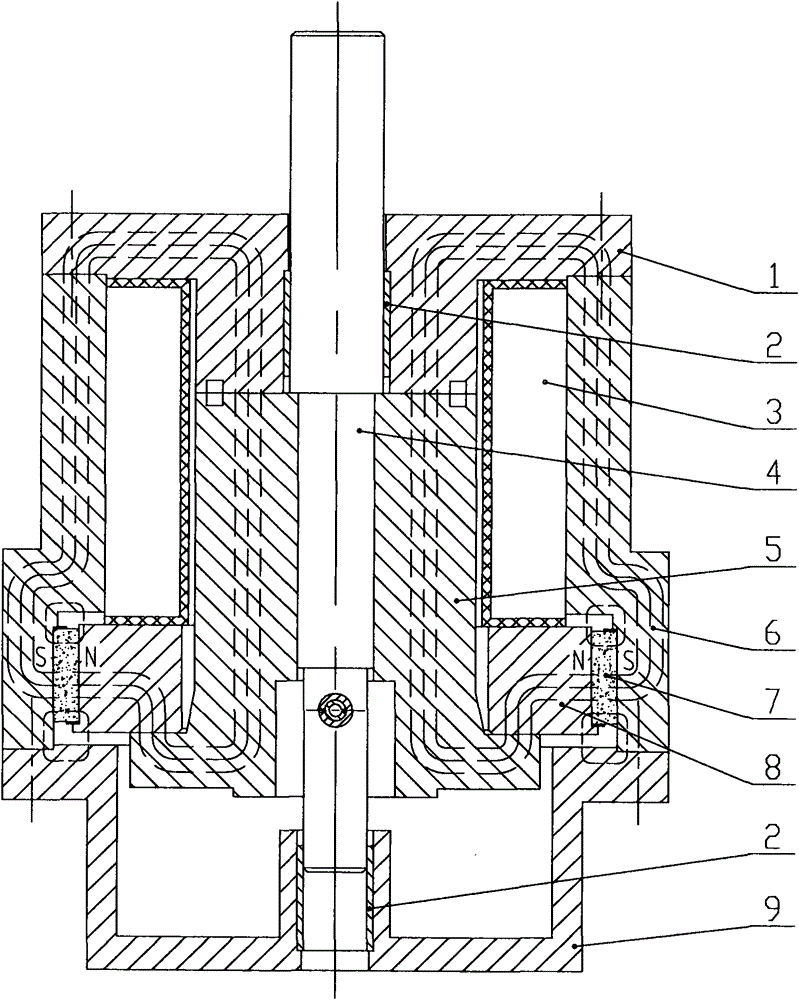

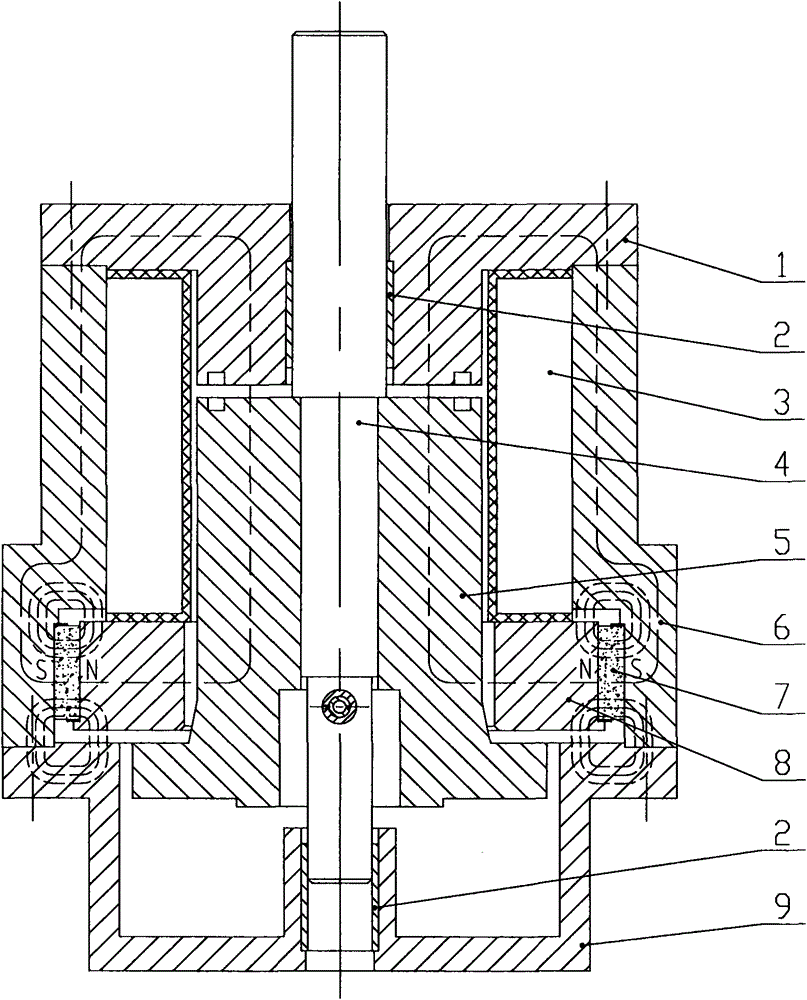

[0015] Such as figure 1 , 2 , 3, the present invention is a parallel magnetic circuit permanent magnet operating mechanism with adjustable holding force, including an upper yoke (1), a self-lubricating bearing (2), a closing and opening coil (3), a push rod ( 4), moving iron core (5), outer magnetic yoke (6), permanent magnet (7), inner magnetic yoke (8) and lower magnetic yoke (9), it is characterized in that: upper magnetic yoke (1) and lower magnetic The center hole of the yoke (9) is respectively embedded with self-lubricating bearings (2), and is fastened on the outer yoke (6) with variable diameter; the permanent magnet (7) has a chamfered inner yoke (8) and The outer yoke (9) is sealed with structural glue; the ejector rod (4) is fixed on the moving iron core (5) with a chamfer and a boss below, and runs through the upper yoke (1) and the lower yoke (9). ); the closing and opening coil (3) is placed in the cavity above the inner yoke (6).

[0016] Wherein there is a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap