A kind of preparation method of graphene conductive alumina ceramics

A technology of alumina ceramics and graphene, which is applied in the field of composite functional ceramic materials, can solve problems such as limited application development, high cost, and production difficulties, and achieve the effects of improving economic and practical value, overcoming bubbling, and broadening the application surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

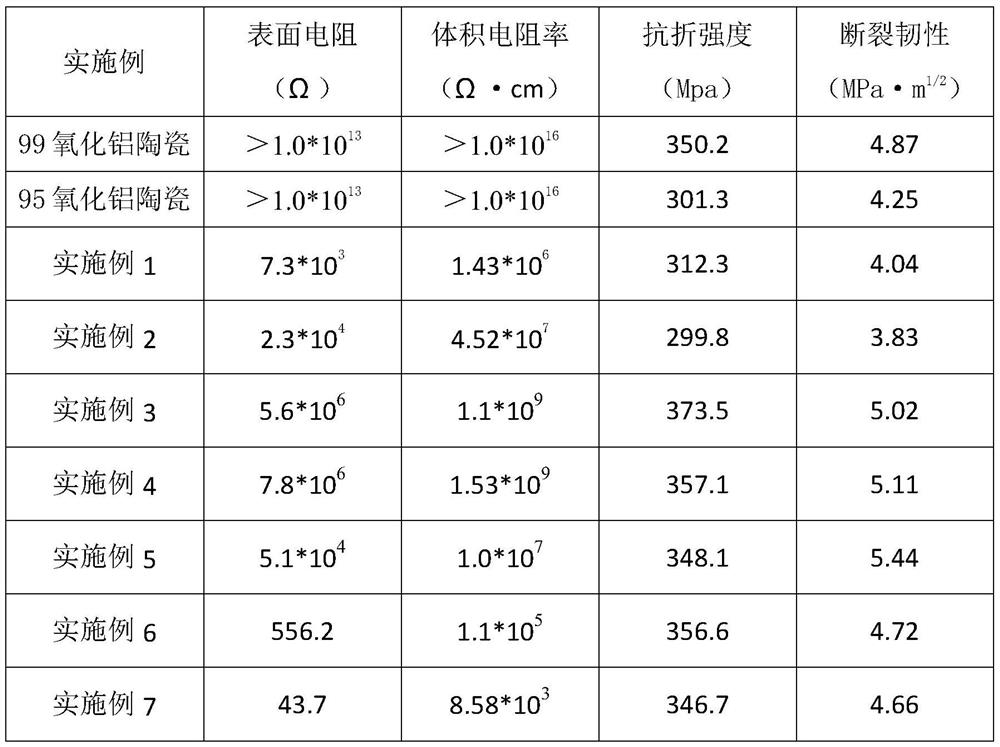

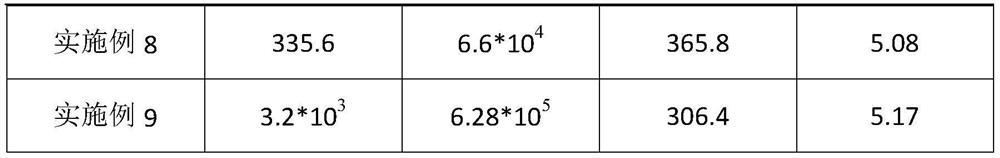

Examples

Embodiment 1

[0035] (1) Dispersion of graphene in liquid silica gel:

[0036] The selected features are: lamellar structure, number of layers ≤ 5 layers, stack thickness -3 Ω·cm graphene powder 5g; divided into two parts on average, added to the AB two-component addition type liquid silicone gel that meets the conditions, that is, 2.5g graphene powder was added to component A, and 2.5g graphene powder was added to component B. Add 2.5g graphene powder (if the two components are mixed in advance, it is easy to be partially overheated and vulcanized during the ultrasonic treatment process, and because there is a certain room temperature operating time, in order to prevent the silicone gel from vulcanizing in advance, so in Before the graphene is completely dispersed, the two parts cannot be mixed together), and then use 1KW ultrasonic power to ultrasonically disperse the silicone gels of components A and B added with graphene for 2hrs, and keep the temperature of the system <30°C ; The preferre

Embodiment 2

[0047] (1) Dispersion of graphene in liquid silica gel:

[0048] The selected features are: lamellar structure, number of layers ≤ 5 layers, stack thickness -3 Ω·cm graphene powder 5g; divided into two parts on average, added to the AB two-component addition type liquid silicone gel that meets the conditions, that is, 2.5g graphene powder was added to component A, and 2.5g graphene powder was added to component B. Add 2.5g of graphene powder, and then use 1KW of ultrasonic power to ultrasonically disperse the silicone gels of components A and B added with graphene for 2hrs, and keep the temperature of the system <30°C; The mass ratio of the two-component silica gel is: graphene: two-component silica gel (component A + component B) = 1:12.5.

[0049] (2) Compounding, surface treatment and drying of alumina powder:

[0050] Four alumina powders with different particle sizes that meet the characteristic conditions are selected to be packed according to the Horsfield dense packing t

Embodiment 3

[0059] (1) Dispersion of graphene in liquid silica gel:

[0060] The selected features are: lamellar structure, number of layers ≤ 5 layers, stack thickness -3 Ω·cm graphene powder 5g; divided into two parts on average, added to the AB two-component addition type liquid silicone gel that meets the conditions, that is, 2.5g graphene powder was added to component A, and 2.5g graphene powder was added to component B. Add 2.5g of graphene powder, and then use 1KW of ultrasonic power to ultrasonically disperse the silicone gels of components A and B added with graphene for 2hrs, and keep the temperature of the system <30°C; The mass ratio of the two-component silica gel is: graphene: two-component silica gel (component A + component B) = 1:12.5.

[0061] (2) Compounding, surface treatment and drying of alumina powder:

[0062] Five kinds of alumina powders with different particle sizes that meet the characteristic conditions are selected to be packed according to the Horsfield dense

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap