Electronegative single-layer organic photoconductor drum and preparation method thereof

An organic photoconductive drum, negatively charged technology, applied in optics, electrographics, instruments, etc., can solve the problems of inability to meet the normal use of negative electrode photoprinters, low production cost, charge accumulation, etc., to avoid cumbersome preparation processes and improve production. Efficiency, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

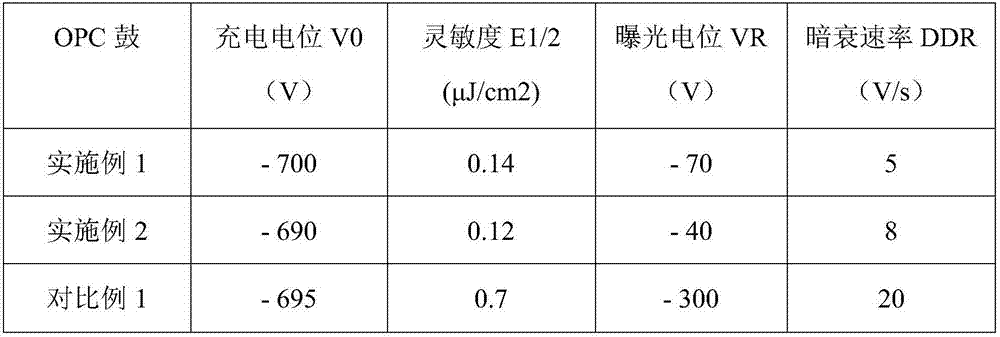

Embodiment 1

[0025] When the mass ratio of PCZ-300: Y-type titanium phthalocyanine: TPD-FCN: S-100 is 100:6:50:100, the preparation steps of the negatively charged single-layer organic photoconductive drum are as follows:

[0026] (1) Dissolving PCZ-300 in tetrahydrofuran to prepare a film-forming agent solution with a mass fraction of 10%;

[0027] (2) The film-forming agent solution prepared by 100g step (1), 1.8g Y-type titanium phthalocyanine and grinding beads are added to the ball mill jar for grinding and dispersing to obtain dispersion A; wherein, the total volume of the grinding beads is 1 / 2 of the volume of the mixed solution in the ball mill tank, the particle size of the Y-type titanyl phthalocyanine in the dispersion A is not greater than 300nm;

[0028] (3) Take 200g of the film-forming agent solution prepared in step (1), add 15g of TPD-FCN and 30g of S-100, and mix well to obtain solution B;

[0029] (4) Mix the dispersion liquid A and the solution B evenly to obtain the co

Embodiment 2

[0031] When the mass ratio of PCZ-300: Y-type titanium phthalocyanine: TPD-FCN: S-100 is 100:6:50:150, the preparation steps of the negatively charged single-layer organic photoconductive drum are as follows:

[0032] (1) Dissolving PCZ-300 in tetrahydrofuran to prepare a film-forming agent solution with a mass fraction of 10%;

[0033] (2) The film-forming agent solution prepared by 100g step (1), 1.8g Y-type titanium phthalocyanine and grinding beads are added to the ball mill jar for grinding and dispersing to obtain dispersion A; wherein, the total volume of the grinding beads is 1 / 2 of the volume of the mixed solution in the ball mill tank, the particle size of the Y-type titanyl phthalocyanine in the dispersion A is not greater than 300nm;

[0034] (3) Take 200g of the film-forming agent solution prepared in step (1), and add 15g of TPD-FCN and 45g of S-100, and mix well to obtain solution B;

[0035] (4) Mix dispersion liquid A and solution B uniformly to obtain a coati

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap