Photocatalyst light emitting diode lamp

A technology of light-emitting diodes and photocatalysts, applied to light sources, point light sources, lighting and heating equipment, etc., can solve problems such as high production and production costs, inconspicuous sterilization and deodorization, and complicated assembly and production processes of photocatalyst light-emitting diode lamps, etc., to achieve The effect of reducing production costs and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

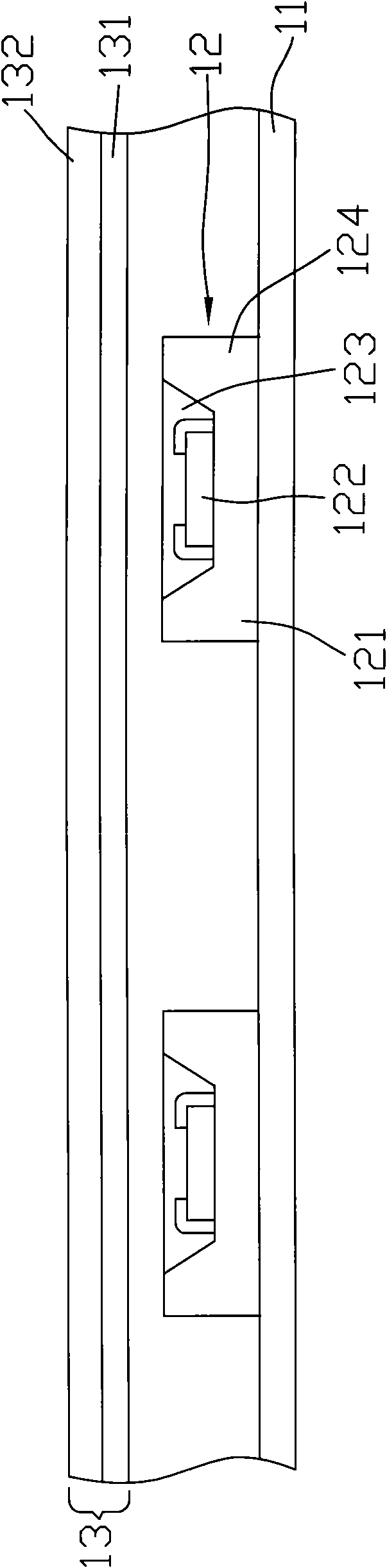

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

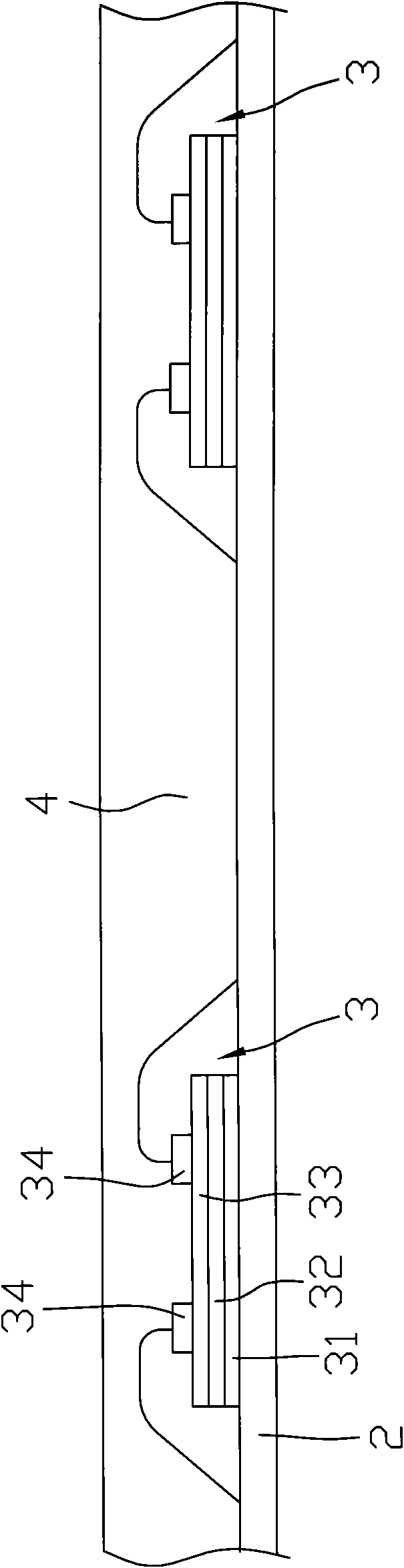

[0021] refer to figure 2 A first preferred embodiment of the photocatalyst light-emitting diode lamp of the present invention comprises a substrate 2, at least one light-emitting diode 3 arranged on the substrate 2, and a layer of photocatalyst formed upward from the substrate 2 for encapsulating the light-emitting diode 3 Layer 4.

[0022] The light emitting diode 3 includes a substrate 31 connected to the substrate 2 , an epitaxial layer 32 extending upward from the substrate 31 , and a transparent conductive layer 33 formed on the epitaxial layer 32 , and two electrodes 34 for electrically connecting with the substrate 2 and electrically connecting with the epitaxial layer body 32 and the transparent conductive layer 33 respectively. It should be noted that a plurality of light emitting diodes 3 are schematically shown in the figure , those skilled in the art

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap