Variable stiffness mechanism and limb support device incorporating the same

a variable stiffness and limb technology, applied in the field of variable stiffness mechanisms, can solve the problems of low energy return, limited stability of high energy return feet, and inability to achieve energy efficient gait patterns, etc., and achieve the effect of high apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

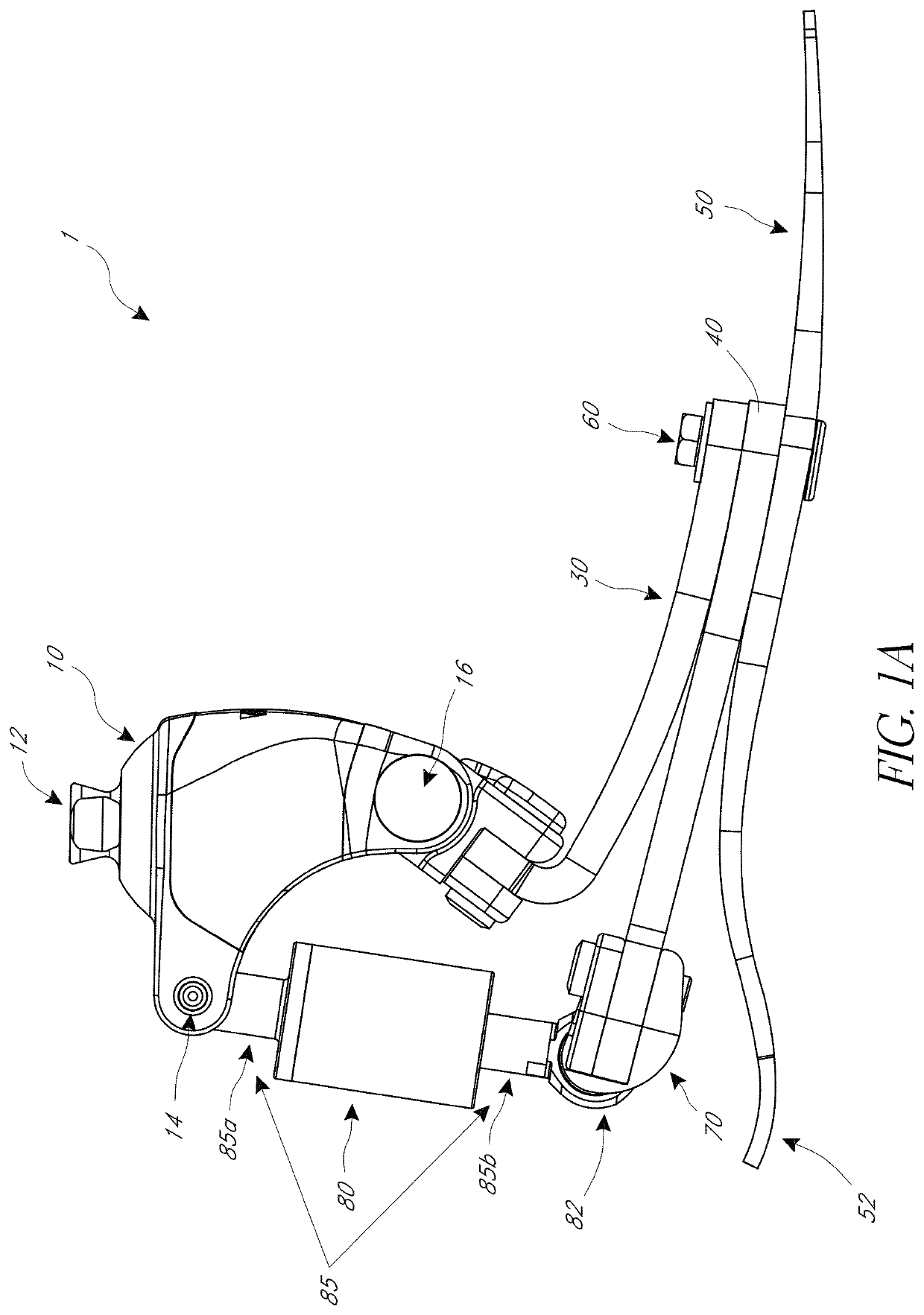

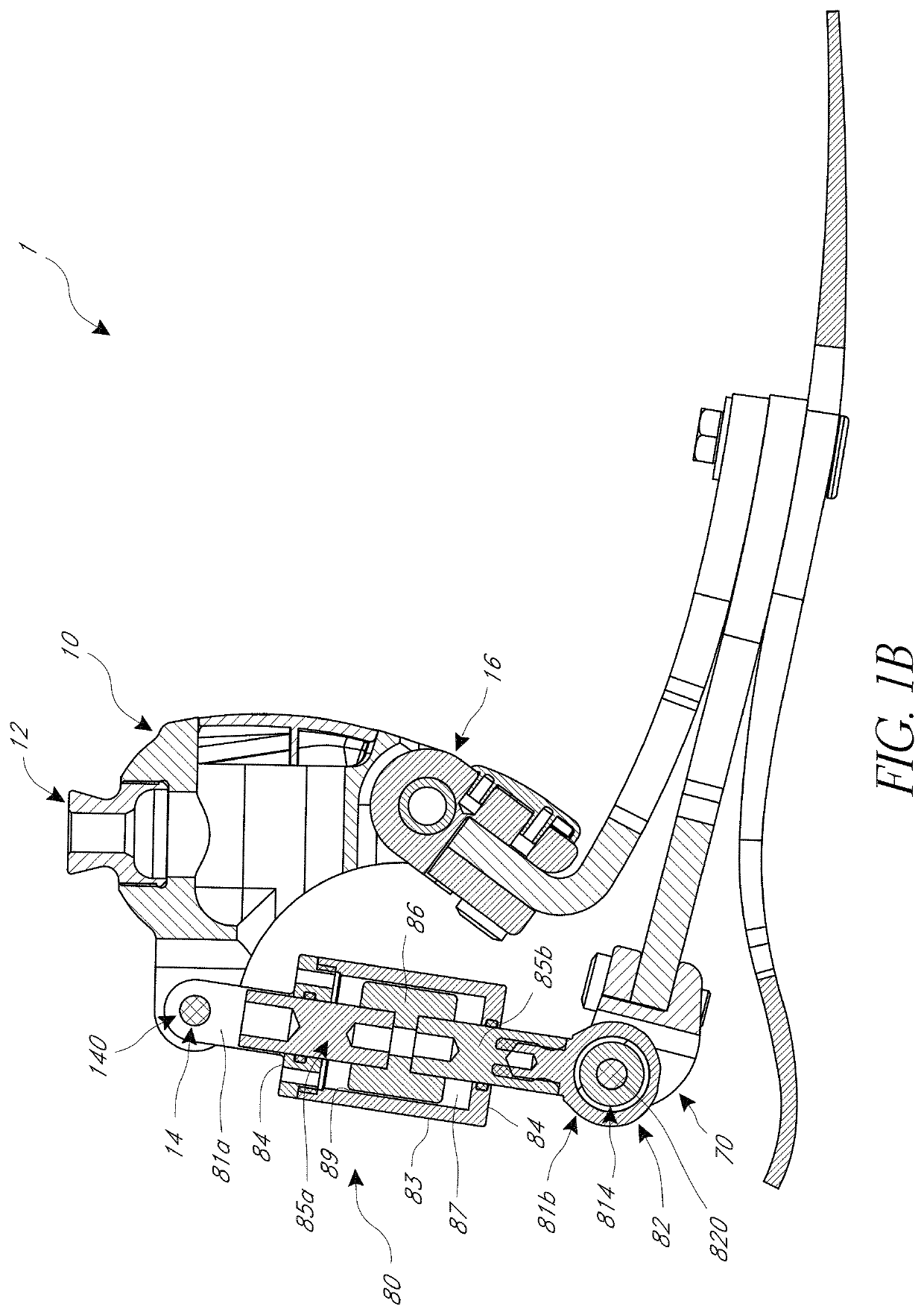

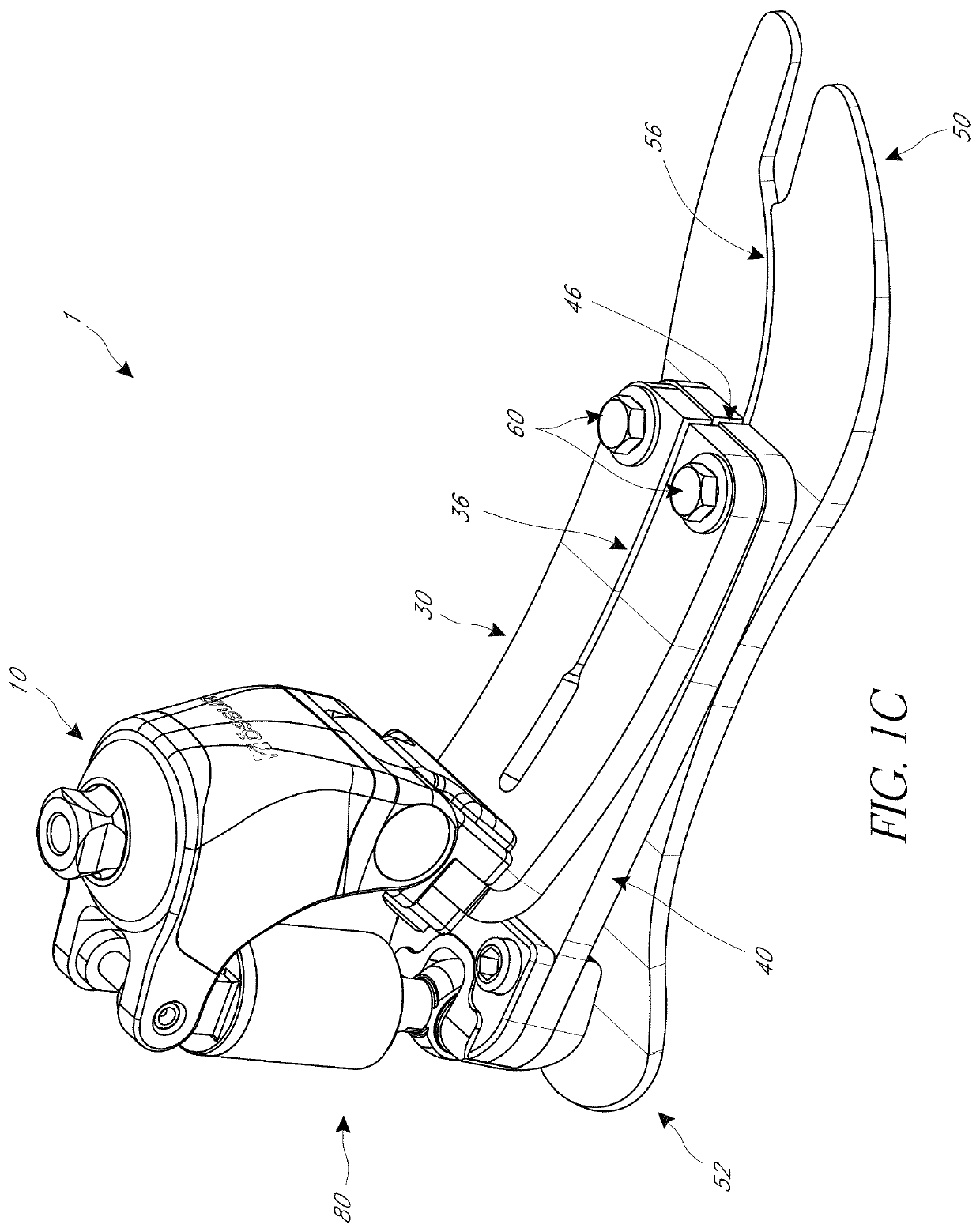

Image

Examples

Embodiment Construction

[0038]A natural human ankle varies its stiffness based on the activity being performed by the user, such as walking at various speeds, rising to stand from a seated position, sitting down, ascending and descending stairs, walking on uneven terrain, and / or running. The ankle can vary between, for example, relatively low stiffness and relatively high damping during slow walking, which can allow for easier transitions, and relatively higher stiffness and relatively lower damping when walking at faster speeds, which can provide greater energy efficiency. Some currently available prosthetic feet are adapted for either high damping, e.g., via a hydraulic mechanism, or high energy efficiency, e.g., via carbon fiber leaf springs. However, such prosthetic feet typically have fixed damping and / or spring characteristics optimized for a particular gait speed on level ground and may not adapt well to other speeds or activities. While prosthetic feet including an electric motor in series with a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap