Furnace wall of contaminated soil pyrolysis or incineration furnace

A technology that pollutes soil and incinerators, applied in incinerators, combustion chambers, combustion methods, etc., can solve the problems of reduced effective volume, inconvenient inspection of carbon deposits, complicated cleaning process, etc., and achieves the effect of easy reinstallation and simple and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

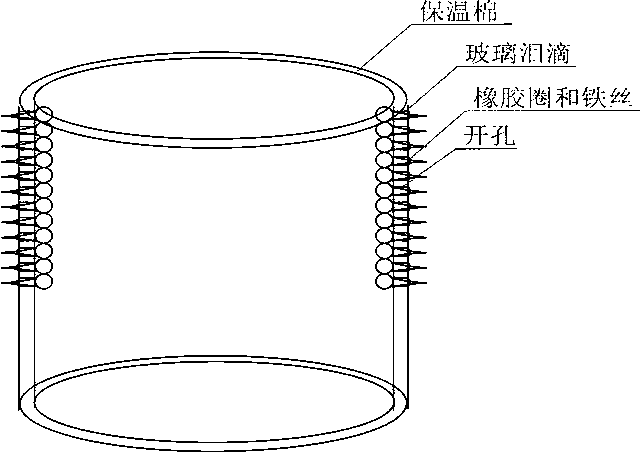

[0008] Implementation method: The sample is contaminated soil from a diesel storage tank. Use 2 cm thick aluminum silicate insulation cotton as the furnace wall with an inner diameter of 20 cm. Use a drilling machine to drill uniform and dense small holes on the furnace wall (covering the middle and upper parts of the furnace wall) , DN 3 mm, hole center spacing 1 cm. Use an alcohol lamp to melt the glass. When melting, it will naturally drop into ice water at 0°C under gravity to form tadpole-shaped glass teardrops. Select the one with a head diameter of about 1 cm and install it on the small hole on the left side of the furnace wall. The head is close to the furnace. On the inside of the wall, the tail protrudes outside, and the outside is fixed with rubber rings and iron wires. As a control, the aluminum silicate insulation wool was cut into a similar shape (head diameter about 1 cm, with a DN 3 mm tail), and installed on the small hole on the right side of the furnace wall.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap