Intelligent metering method for remnant base paper rolls of corrugated paper board assembly line

A measurement method and corrugated cardboard technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as heavy workload, and achieve the effects of improving utilization, reducing operating costs, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

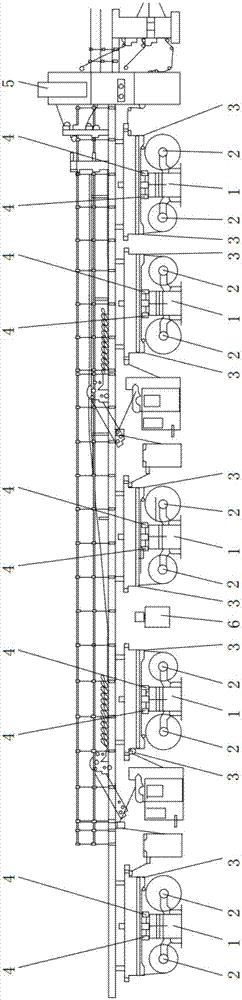

[0045] Attached below figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0046] Such as figure 2 As shown, the intelligent measurement method for base paper remnants in a corrugated cardboard assembly line includes several base paper positions arranged at intervals in the conveying direction of the line, and each of the base paper positions includes a base paper support 1 . In this embodiment, each base paper loading frame 1 is provided with two base paper loading rollers, and the two base paper loading rolls are respectively arranged on both sides of the base paper loading frame 1 .

[0047] Each of the base paper upper rolls is provided with a lap sensor 2 for monitoring the number of laps of the base paper clamped on the base paper upper roll and is used to monitor the number of laps of the base paper clamped on the base paper upper roll. One circle corresponds to an incremental encoder with the len...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap