Combine dual auger unloader

a dual-auger, combine technology, applied in the field of combine or harvester, can solve the problems of reducing future crop yield, limited capacity of on-board primary storage hoppers, and insufficient capacity of no combine commercially available today, and achieves the effect of facilitating retrofitting and increasing unloading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

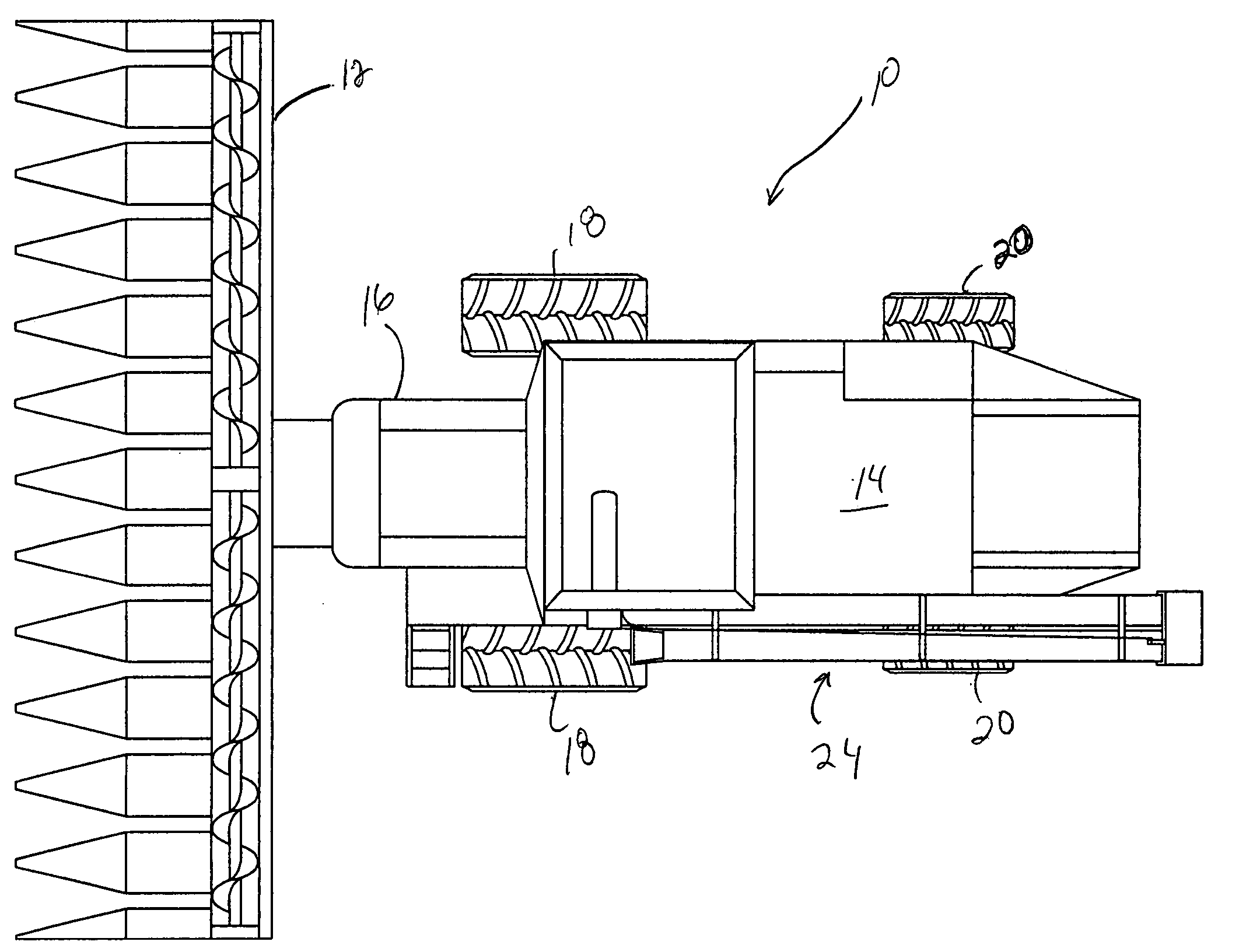

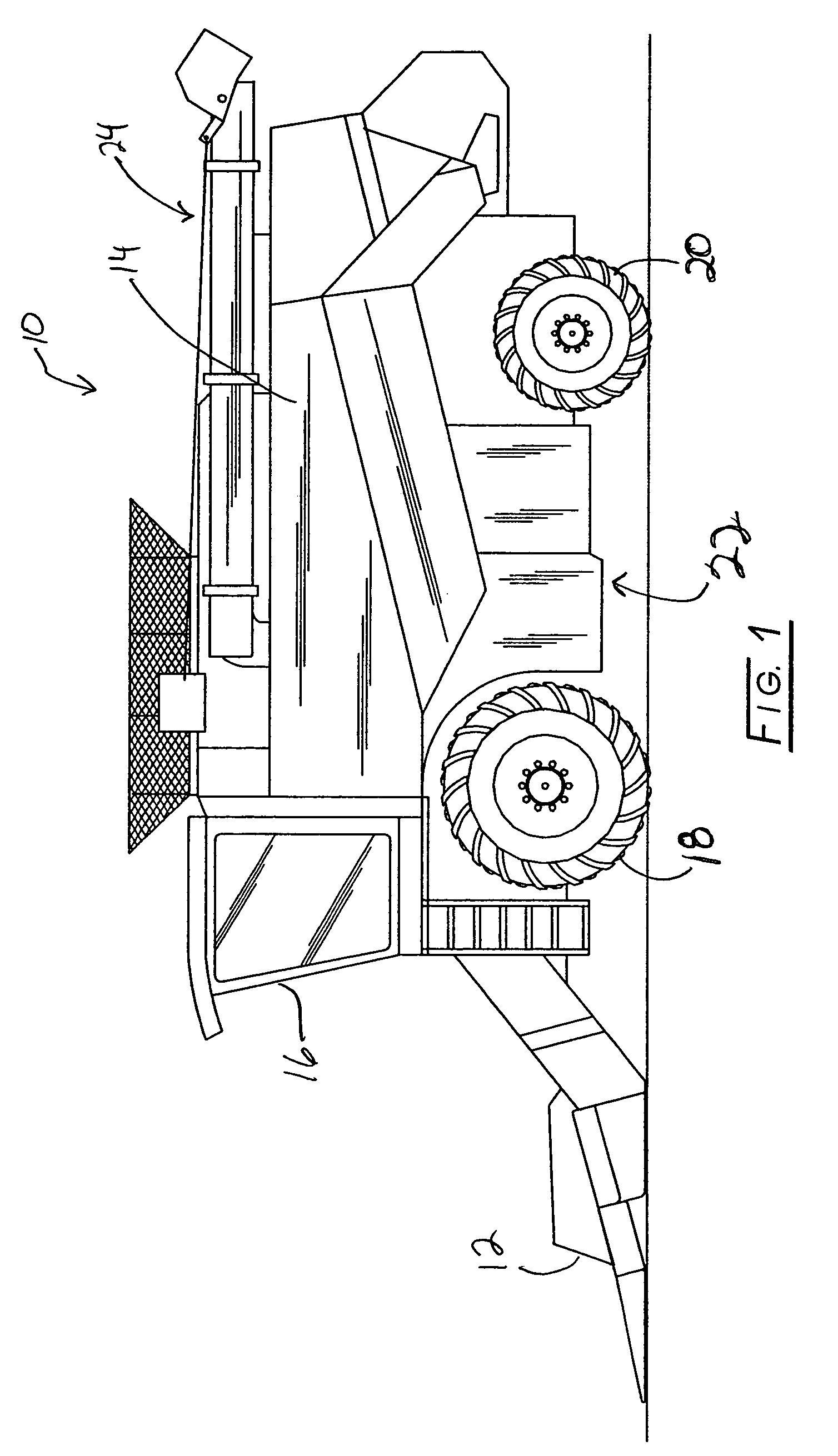

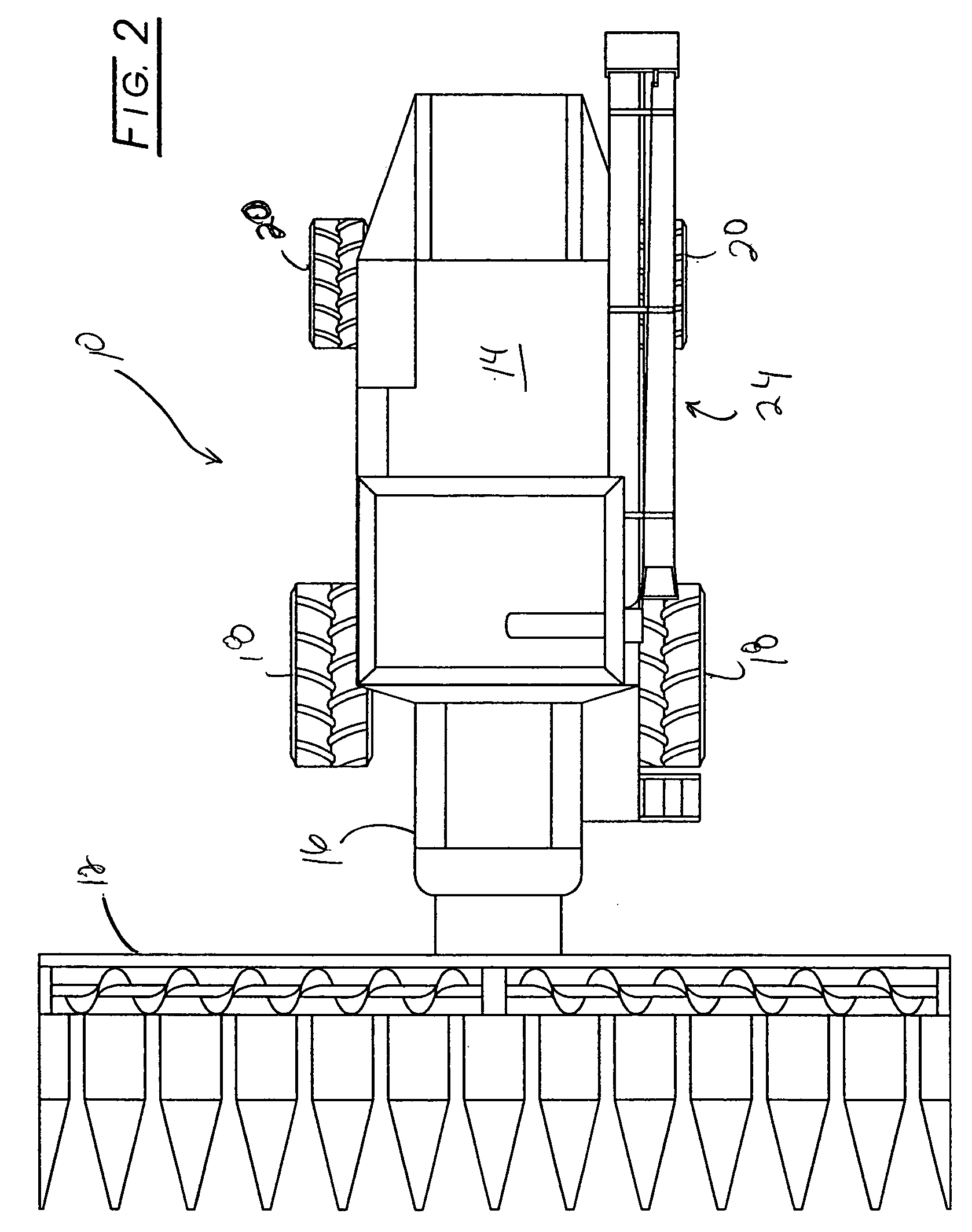

[0027] The present invention is addressed to unloading grain bins rapidly and has applicability to extra capacity grain bins, grain bins that receive more grain that their rated capacity, and the like. Such grain bins most often are carried by combines and grain carts. For present purposes combine and harvester are used interchangeably and no limitation should be implied by use of either term, as an apparatus that harvests grain in the field is broadly meant. So too, there no limitation of the term grain cart should be implied, as grain carts carry a grain bin and can be towed by a combine. Grain carts also can be powered and steerable, such as is disclosed in U.S. Pat. No. 5,904,365. While the invention can be applied to virtually any conventional combine, it has special applicability to combines having grain bins of up to 1000 to 1200 bushel or more capacity, such as are disclosed in one or more of the following patents: U.S. Pat. Nos. 6,012,272, 6,125,618, 6,339,917, 6,604,351, 6,60

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap