High-temperature resisting conveyor belt with diaphragm plates and retaining sides

A conveyor belt, high temperature resistant technology, applied in the field of rubber conveyor belts, can solve the problems of easy separation and falling off of rubber, and achieve the effects of improving service life, improving adhesion and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the accompanying drawings and embodiments.

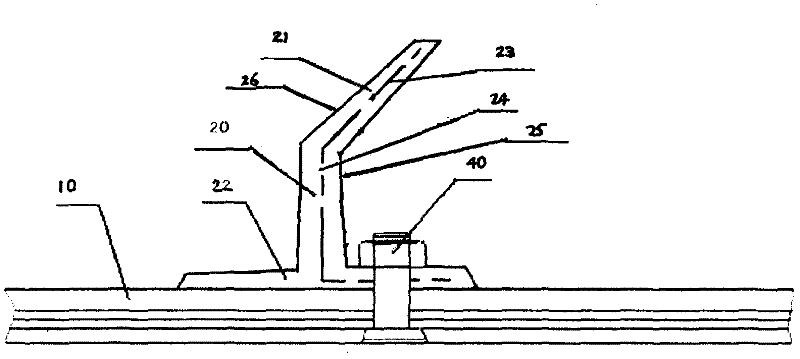

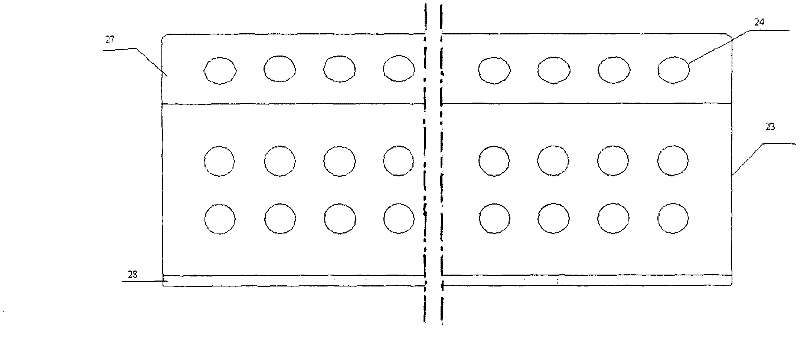

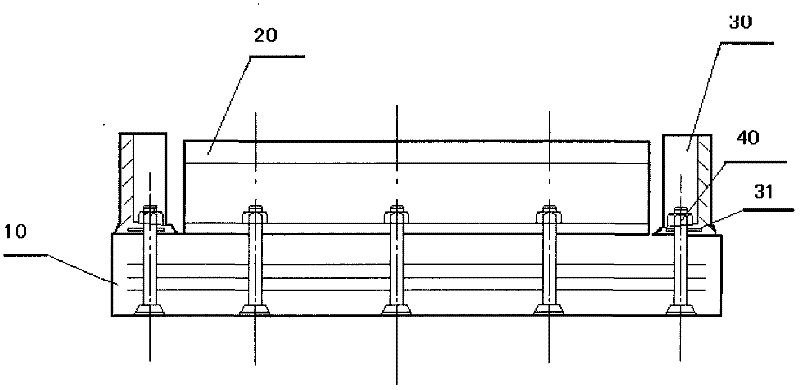

[0011] figure 1 It is a side sectional view of the structure of the high temperature resistant conveyor belt of the present invention. The high temperature resistant conveyor belt includes a base belt 10 and a diaphragm 20 disposed above the base belt 10 . The diaphragm 20 includes inclined ribs 21 above it and a base 22 at the bottom. A metal plate 23 is embedded in the diaphragm 20 , and a plurality of holes 24 are arranged on the metal plate 23 . The diaphragm base 22 and the metal plate 23 inside the diaphragm 20 are fixed on the base tape 10 by screws 40 .

[0012] The present invention adopts the vulcanization method to adhere the metal plate 23 and the rubbers 25 and 26 on both sides of the metal plate, and the rubbers on both sides of the metal plate are also adhered together through the holes. By adopting the above technical solution, the rubber

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap