Embedded special-shaped side-by-side cable

An embedded, first-cable technology, applied in cables, insulated cables, flat/ribbon cables, etc., can solve the problem of high production cost of side-by-side cables, and achieve the effect of reducing production costs and achieving stable and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

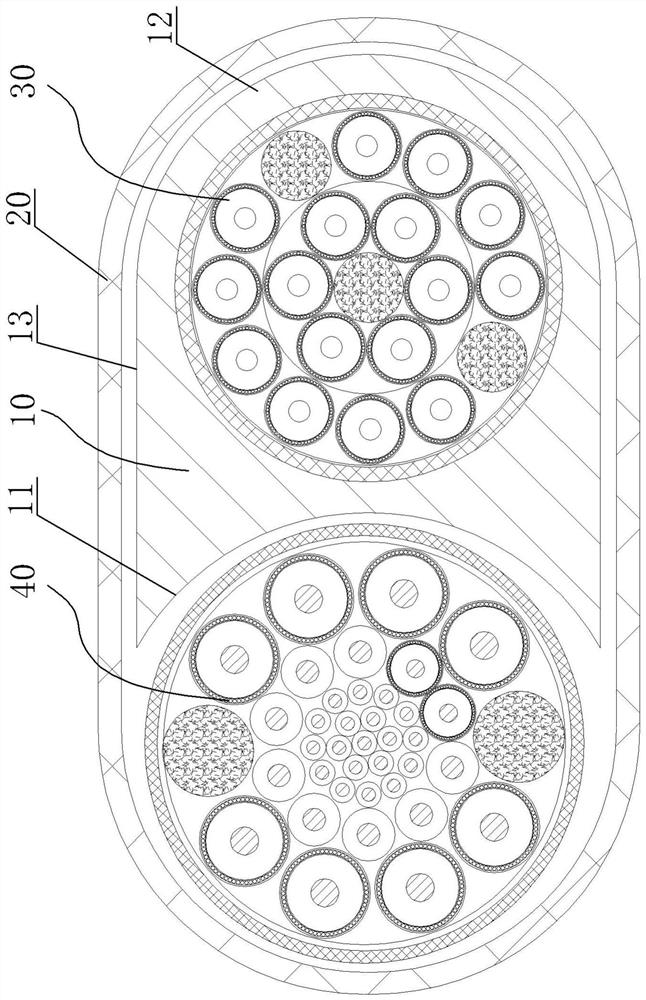

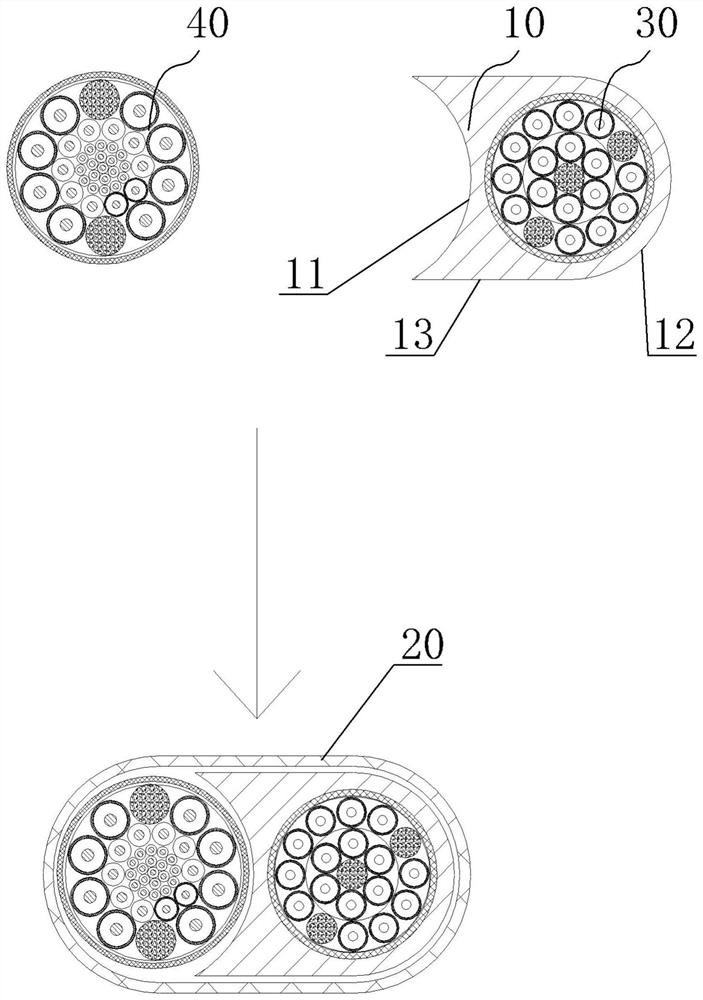

[0024] Specific embodiment one, see figure 1 and figure 2 : when N equals 2, it includes a first cable 30 and a second cable 40, the outer diameter of the second cable 40 is greater than the outer diameter of the first cable 30, and the cable covering sheath 10 wraps the first cable 30 is wrapped in the center, one side of the cable covering sheath 10 is an arc protrusion 12, the other side of the cable covering 10 sets is a concave cable arc cavity 11, and the cable covering sheath 10 The upper end and the lower end of both are flat surfaces 13, the second cable 40 is embedded in the concave cable arc cavity 11, and the coating fiber layer 20 is coated on the combination of the two cables and the cable coating sheath 10. The periphery of the overall structure.

specific Embodiment 2

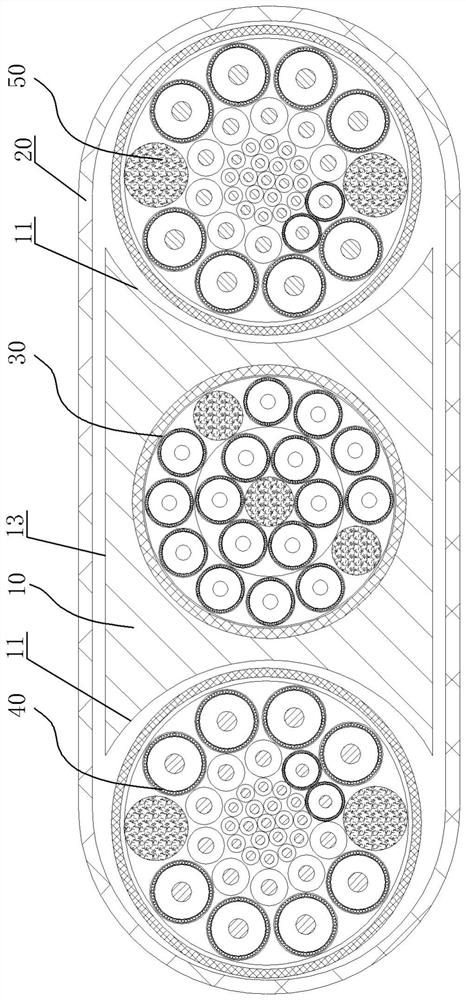

[0025] Specific embodiment two, see image 3 and Figure 4 : when N is equal to 3, it includes a first cable 30, a second cable 40, and a third cable 50, the outer diameters of the second cable 40 and the third cable 50 are larger than the first cable 30, and the cable The covering sheath 10 wraps the first cable 30 in the center, and the two sides in the width direction of the cable covering sheath 10 are concave cable arc cavities 11, and the upper and lower ends of the cable covering sheath 10 are Both are flat surfaces 13, the second cable 40 and the third cable 50 are respectively embedded in the concave cable arc cavity 11 of the corresponding size, and the covering fiber layer 20 covers the three cables and the cable covering sheath 10; when the outer diameters of the second cable 40 and the third cable 50 are the same, the sizes of the concave cable arc cavities 11 on both sides are the same.

[0026] In specific embodiments 1 and 2, the coated fiber layer 20 is specifi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap