Connection structure between vacuum cleaner motor stator enamelled wire connection end and connection terminal

A technology of connection terminal and motor stator, which is applied in the field of connection structure between enameled wire connection port and connection terminal of vacuum cleaner motor stator, can solve the problems of increasing process and working hours, irregular appearance, affecting flow operation, etc., to achieve neat appearance, The effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The connection structure of the enameled wire connection port and the connection terminal of the stator enameled wire of the vacuum cleaner motor according to the present invention will be described below with reference to the drawings and specific embodiments.

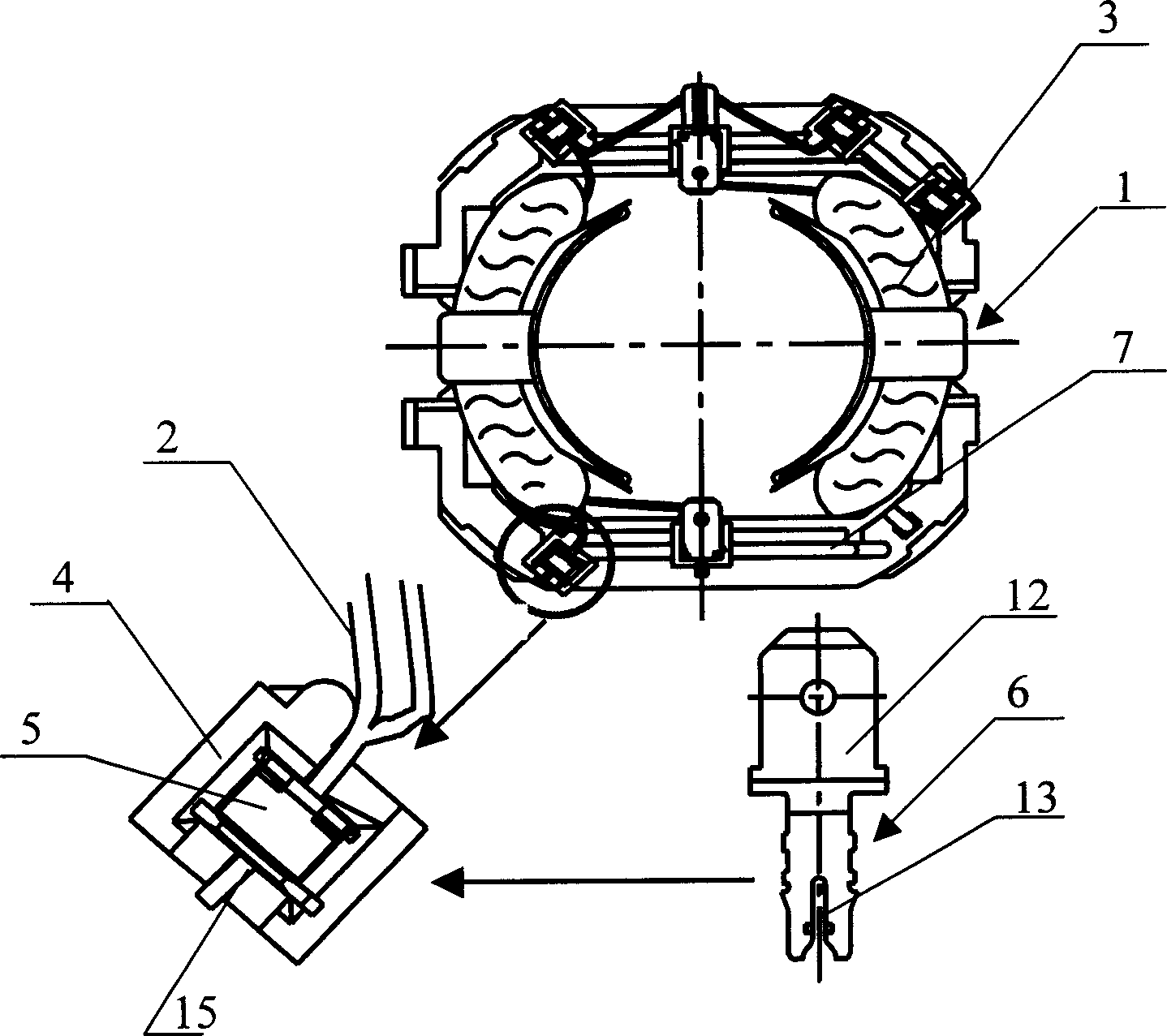

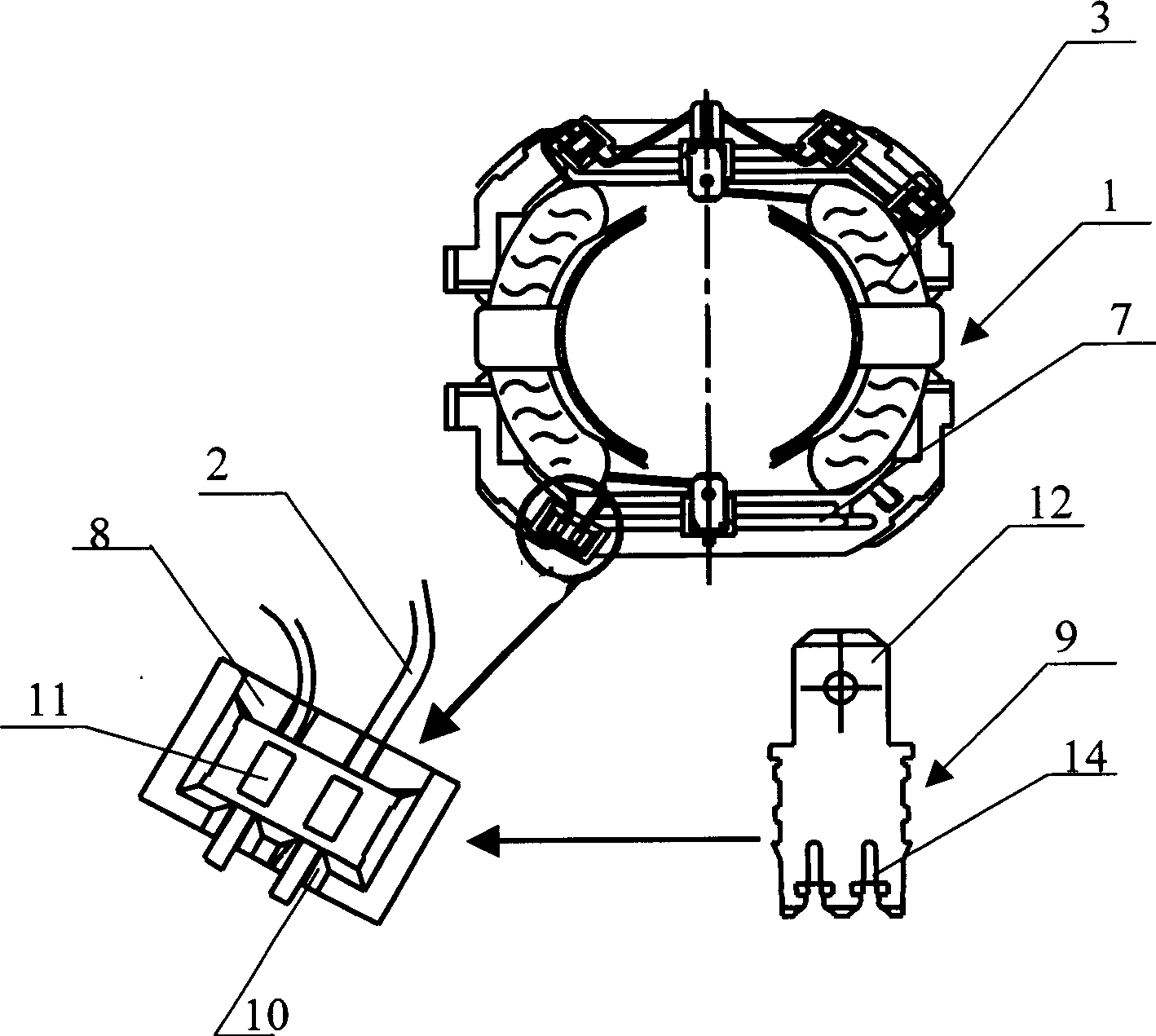

[0016] Such as figure 2 As shown, the connection structure between the enameled wire connection port and the connection terminal of the vacuum cleaner motor stator of the present invention includes a coil 3 wound by enameled wire 2 wound on the iron core of the stator 1, and an insulating frame 7, which connects two The connection port 8 and the connection terminal 9 of the above enameled wire 2; wherein the connection port 8 is arranged on the insulating frame 7, and in the connection port 8 and through both sides of the connection port 8, more than two can be formed. Through the wire groove hole 10 of the enameled wire 2, on the upper end surface of the connection port 8, at the position corresponding to the wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap