Chassis for nozzle with air guiding element

A technology of air guiding components and chassis, which is applied in the direction of suction nozzles, household appliances, applications, etc. It can solve the problems of pushing the suction nozzle, getting stuck, and the suction nozzle can only move by jumping, so as to avoid sticking and vacuuming The effect of effect promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following description of the different exemplary embodiments according to the invention, components and elements which have the same function and mode of operation are marked with the same reference numerals, even if these components and elements have different dimensions in the different exemplary embodiments or shape.

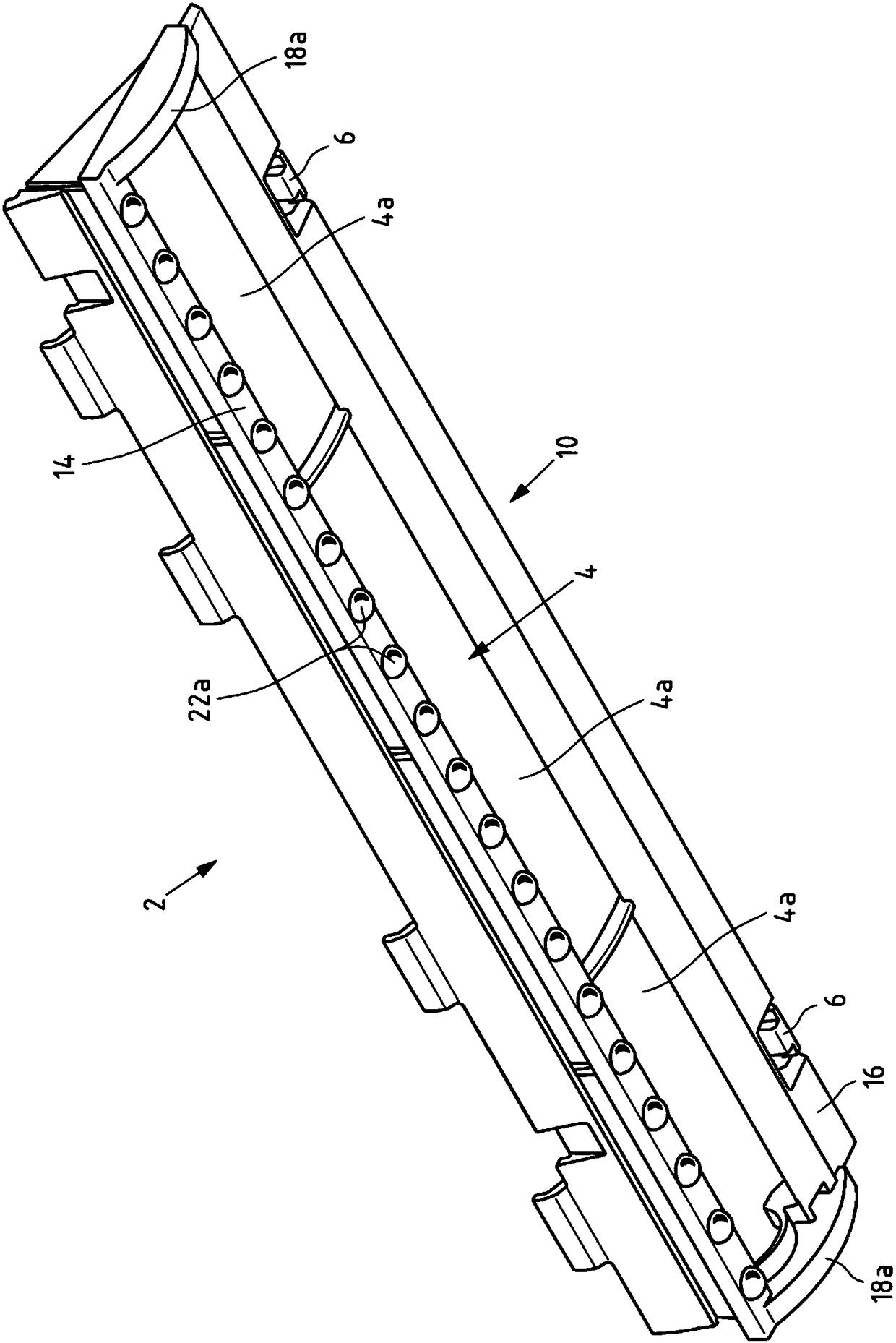

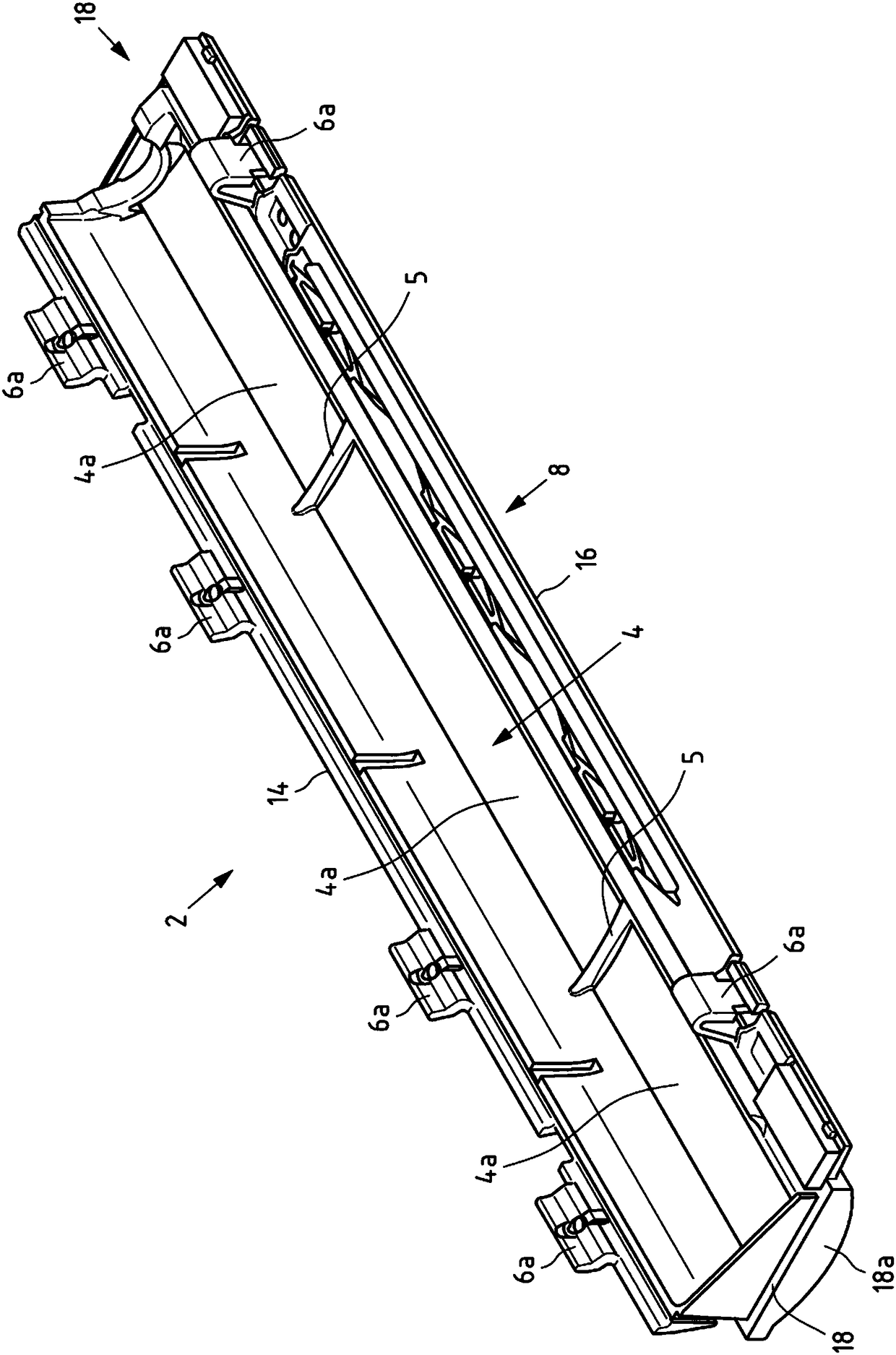

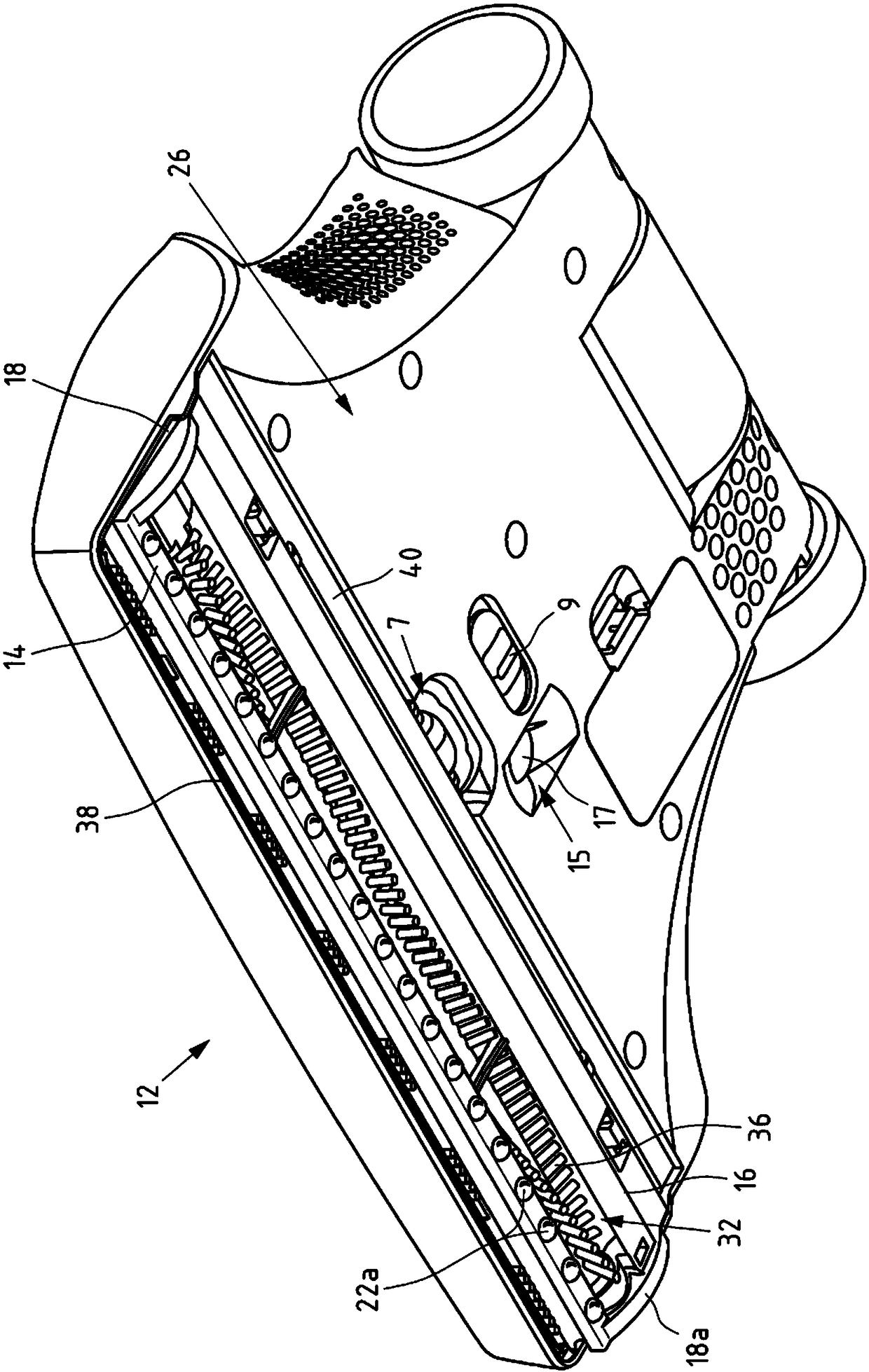

[0036] figure 1 A perspective view obliquely below is shown of a first exemplary embodiment of a chassis 2 for suction nozzles 12 according to the invention. The bottom surface 10 of the undercarriage 2 is thus shown in this view. Here, the undercarriage 2 has a suction opening 4 which is delimited by and thus defined by a front edge 14 , a rear edge 16 and two side edges 18 . The edges 14 , 16 and 18 not only delimit the suction opening 4 but also form planar sections of the chassis 2 . Additionally, the side edges 18 are formed as bearing blocks 18a.

[0037] Attached on the upper side of the front edge 14 and the rear edge 16 are connecting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap