Self-cleaning kneading reactor

A reactor, self-cleaning technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, chemical/physical/physicochemical processes, etc. The industrial application of screw extruders and the inability to update the interface can achieve the effects of improving heat transfer efficiency and mixing efficiency, reducing thermal loss, and narrow residence time distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

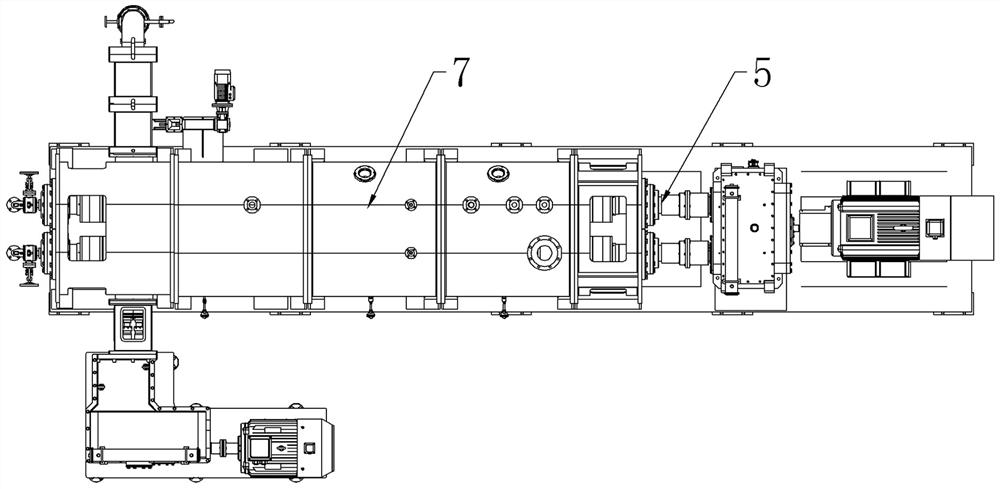

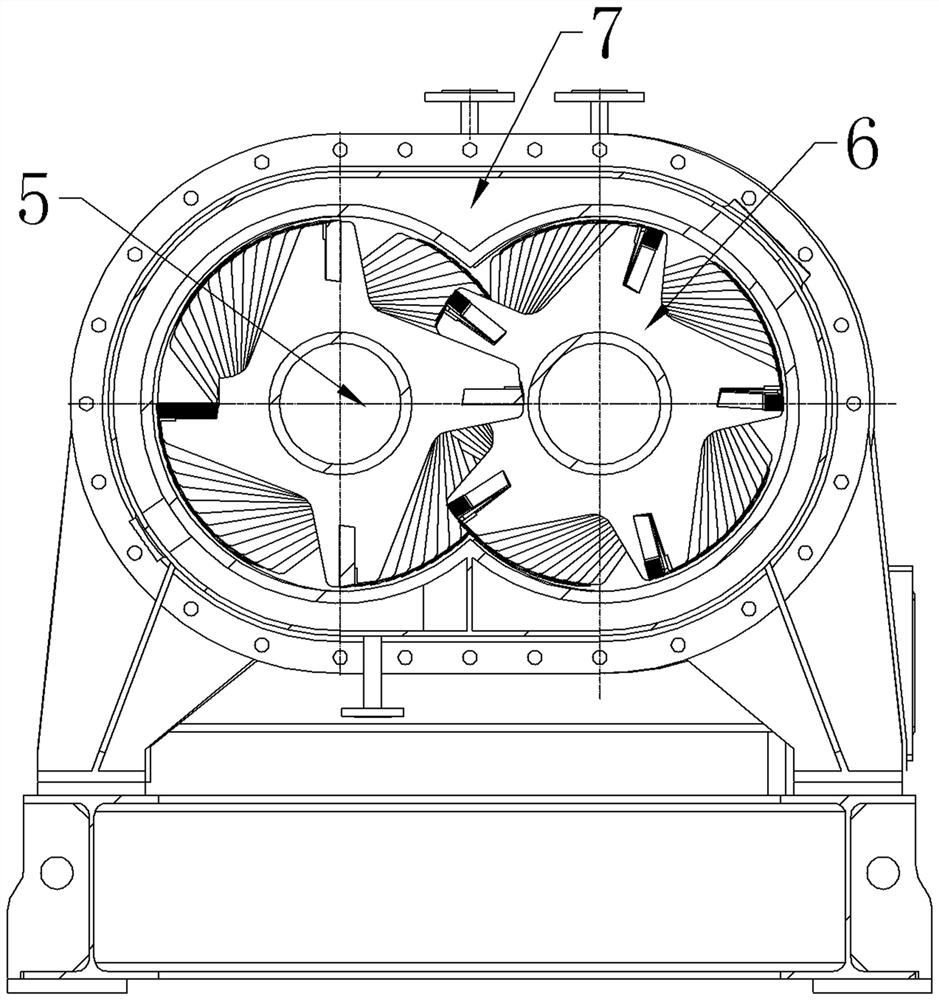

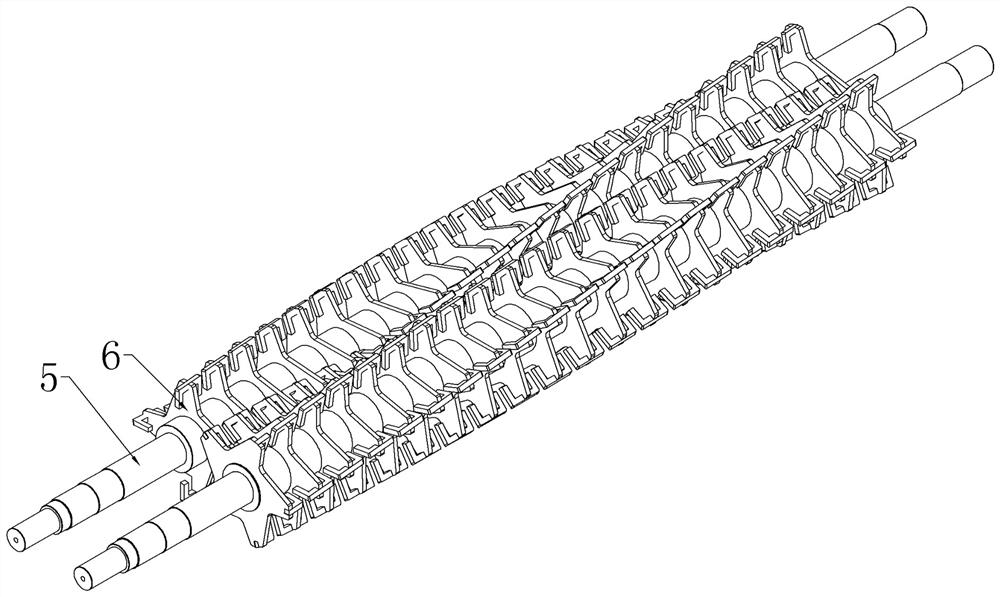

[0042] Such as Figure 1-5 Shown: a self-cleaning kneading reactor, including a cylinder 7 and a stirring rotor 5, inside the cylinder 7 with an "8" cross-section, there are two stirring rotors 5 arranged in parallel in pairs, and the stirring rotor 5 is set There are impellers 6 arranged in a helical dislocation in order, and the misalignment angle between any adjacent impellers 6 on the same stirring rotor 5 is 3° to 10°, and the adjacent impellers 6 on the two stirring rotors 5 are also misaligned ( The misalignment angle between the impeller 6 of one stirring rotor 5 and the two adjacent impellers 6 on the other stirring rotor 5 is 1.5°~5°), so that the E-shaped scrapers on the adjacent impellers 6 on the two stirring rotors 5 can mutually The intermeshed E-type scrapers can clean up the high-viscosity fluid adhering to the E-type scrapers, the rotor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap