Vane-type pneumatic mineralizing equipment and pneumatic flotation cell using same

A mineralizer and blade-type technology, which is applied in the field of flotation separation process of coal selection, can solve the problems such as not suitable for metal mineral flotation, low kinetic energy conversion rate of ore pulp, difficult technology promotion, etc., and achieves easy operation. Control and control, reduce the amount of equipment maintenance, and improve the effect of mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

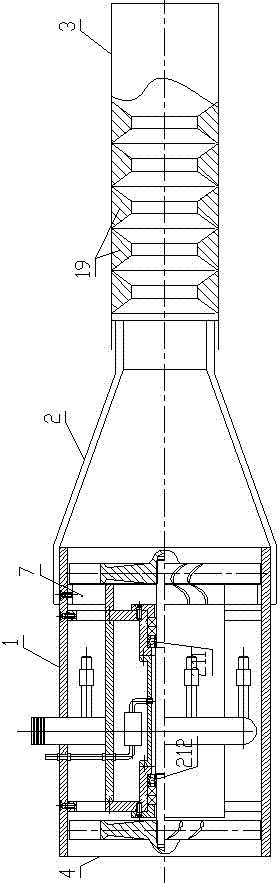

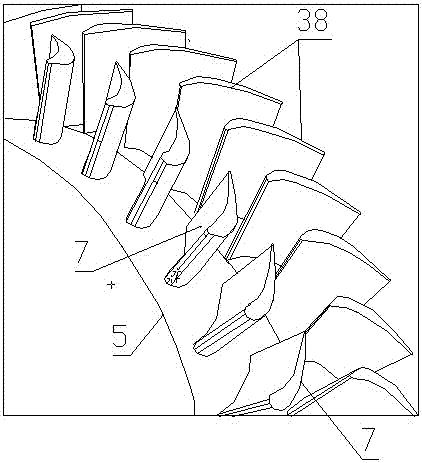

[0038] Such as Figure 1 to Figure 6 As shown, the vane-type pneumatic mineralizer of the present invention includes a cylindrical shell 1, with the pulp flow direction as the forward direction, the front and rear ends of the shell 1 are open, and the rear end of the shell 1 is opened as the pulp inlet. 4; The front end of the shell 1 is connected with a shrinking tube 2, the diameter of the shrinking tube 2 is larger at the rear and smaller at the front,

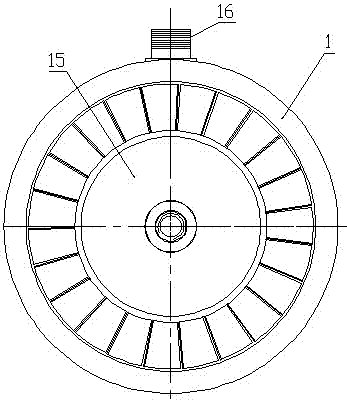

[0039] The housing 1 is provided with a central shaft 9, the front end of the central shaft 9 is connected with a power impeller 14, and the rear end of the central shaft 9 is connected with a slurry suction impeller 15; the power impeller 14 is located at the front end of the housing 1, and the slurry suction impeller 15 is located at the Rear end; the front end of central shaft 9 is equipped with front bearing 211, and front bearing 211 is supported by front bearing frame 81, and front bearing frame 81 is installed on the ho

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap