Structure of turbine blade wheel weight reducing for pressurizer

A turbocharger turbine and new structure technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of uneven mass distribution of supercharger rotors, insufficient linear speed, insufficient welding strength, etc., and achieve mass production The production economic benefit is obvious, the effect of reducing weight and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is given in detail by the following examples.

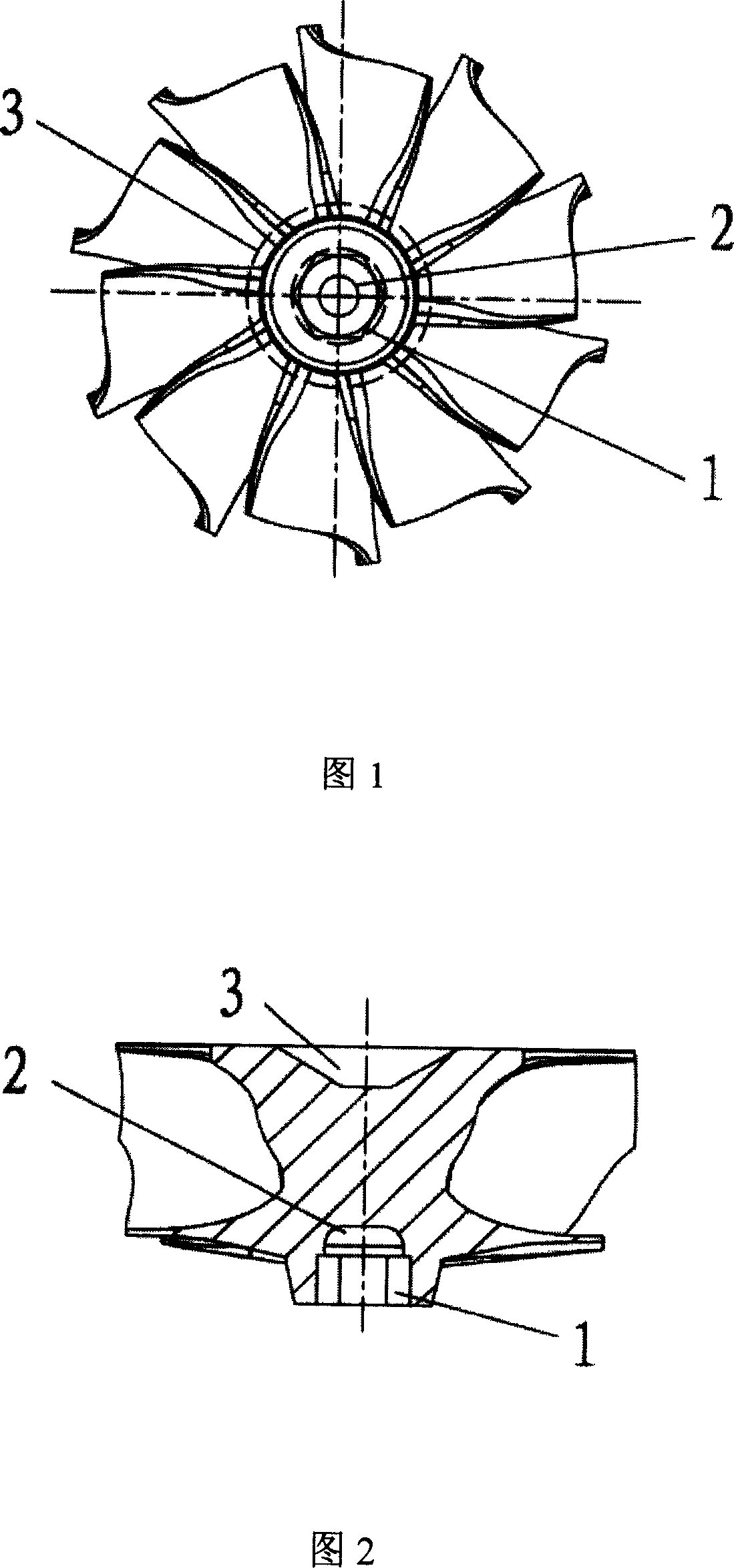

[0018] The supercharger turbine impeller lightening type structure is characterized in that: the inner hexagon (1) is concentric with the turbine impeller and is located outside the weight reducing hole (2) for the positioning and assembly of the supercharger rotor; the weight reducing hole (2) Concentric with the turbine impeller, located inside the inner hexagon (1) and communicated with it; the friction welding taper hole (3) is located on the back side of the wheel, concentric with the turbine impeller, used for friction welding with the shaft, and can increase the effectiveness of friction welding welding area.

[0019] Product manufacturing implementation mode: The product of the present invention is to effectively reduce the weight of the turbocharger parts and components on the basis of not changing the blade shape and flow channel and ensuring the performance and struc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap