Novel rack

A rack, a new type of technology, applied to components with teeth, gear lubrication/cooling, belt/chain/gear, etc., can solve problems such as poor lubrication, large vibration, and large noise, to ensure normal operation, Low manufacturing cost and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0009] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

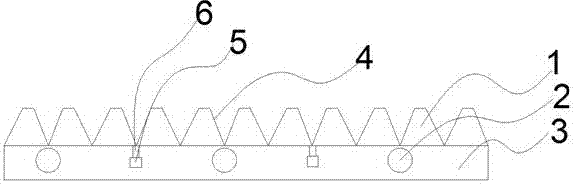

[0010] Such as figure 1 Shown is a new type of rack, which includes a rack body, gear teeth are set on the rack body, bearing rings are set inside the rack body, special coatings are provided on the surface of the gear teeth, and gear teeth are set on the rack body The oil storage grid is provided with guide strips on the oil storage grid. As a preference, the oil storage grid is evenly distributed on the rack body, and is connected to the gear teeth through a guide strip. As a preference, the specia

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap