Laser film surface coating system

A technology of surface coating and laser film, which is applied to devices and coatings for coating liquids on the surface. Uniform, fully coated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

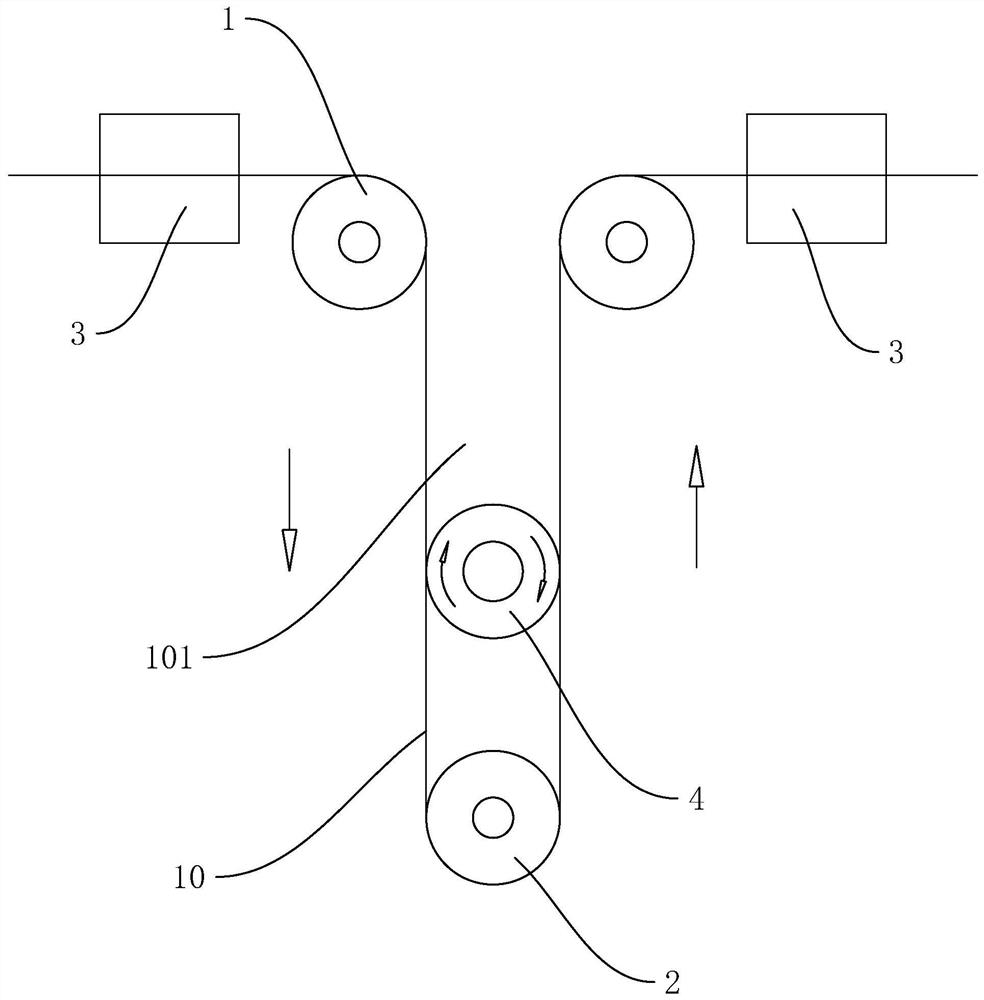

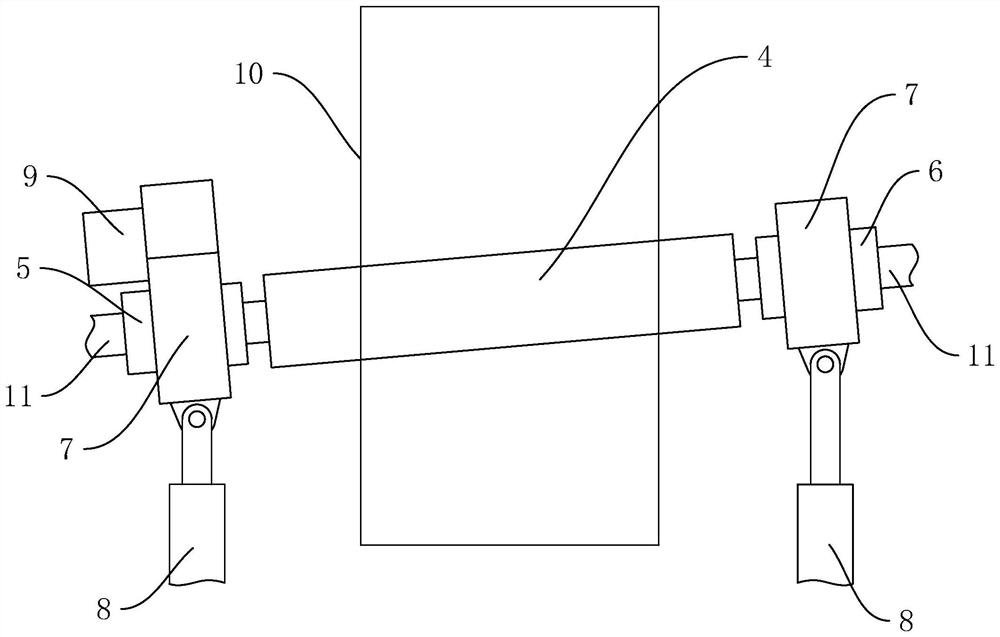

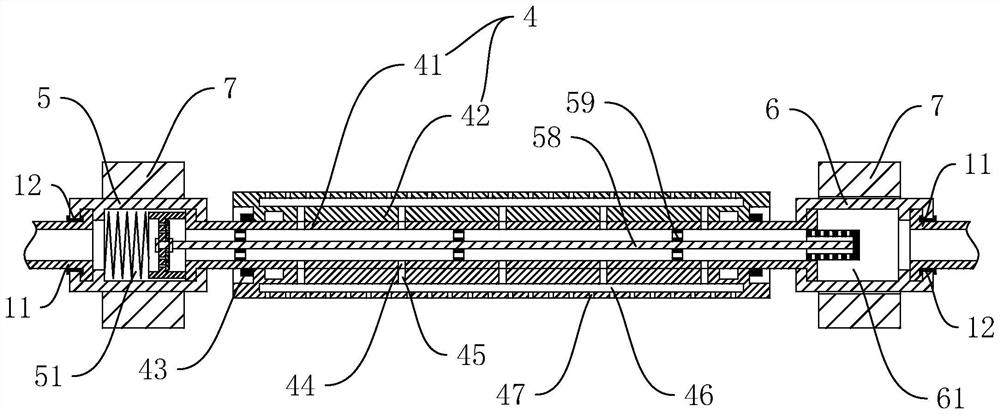

[0035] This embodiment discloses a laser film surface coating system, such as figure 1 , 2 As shown, it includes a coating roller 4 and a guide roller assembly. The guide roller assembly is used to transmit the laser film 10. During the conveying process, the two sides of the laser film 10 pass through the outer circumference of the coating roller 4 and contact each other. The outer peripheries of the cloth rollers 4 are in contact wit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap