Submerged arc welding method for BB503 steel plate welded joint of 100mm thick blast furnace shell

A technology of BB503 and welded joints, which is applied in the field of submerged arc welding, can solve problems such as complex working conditions, and achieve the effect of strong practicability and excellent strength and toughness matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

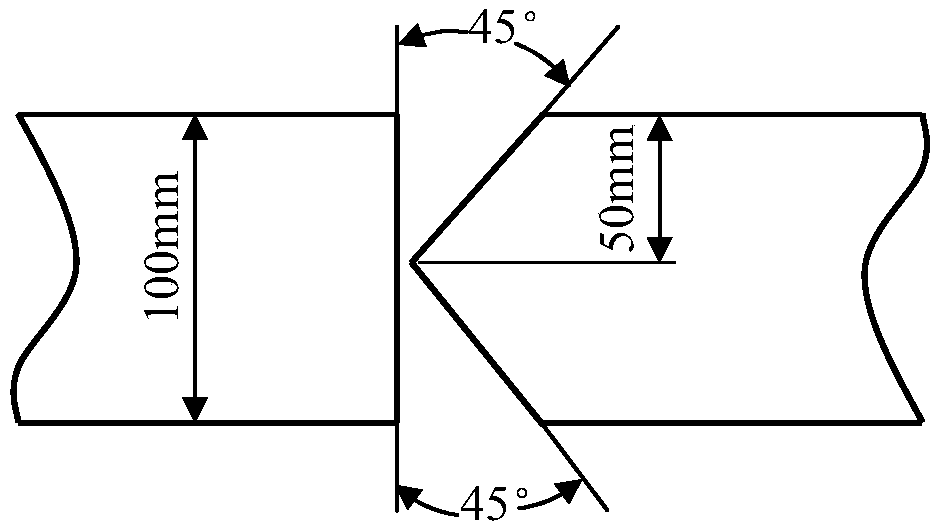

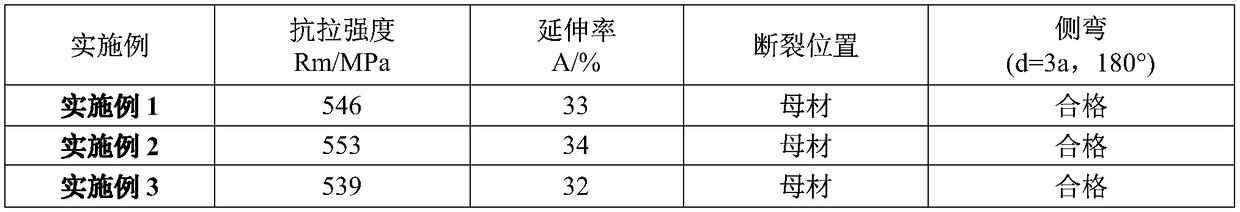

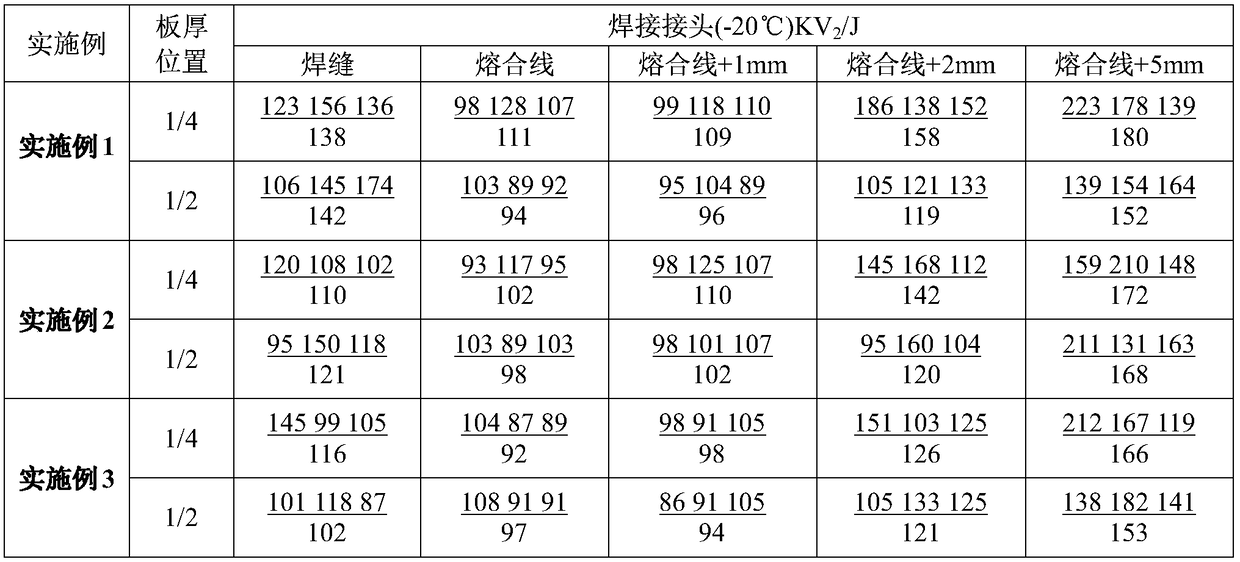

[0029] A submerged arc welding method with excellent strength and toughness of BB503 steel plate welding joints for 100mm thick blast furnace shells. The 100mm thick blast furnace shells delivered in normalizing state use BB503 steel plates with excellent strength and toughness. The welding test plate combination is 100mm+100mm. The plate size is 900mm (length) × 200mm (width) × 100mm (thickness), and the submerged arc welding is completed. Table 1 shows the properties of the steel plate base materials of Examples 1, 2, and 3.

[0030] Table 1 Base metal properties

[0031] Example

Rp0.2 / MPa

Rm / MPa

A / %

(-20℃)KV 2 / J

Example 1

365

563

30

272,261,285

Example 2

368

549

33

244,212,231

Example 3

344

531

32

265,241,256

[0032] The flux matching the welding wire is 880M, and the mechanical properties of the corresponding submerged arc welding deposited metal: tensile strength ≥ 540MPa, yiel

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap