Heating device special for aircraft oil tank

A technology of heating device and lubricating oil tank, applied in the aviation field, can solve problems such as fire hazards, achieve the effects of good manufacturability, ensure contact, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A heating device of the present invention is described in detail in conjunction with the accompanying drawings:

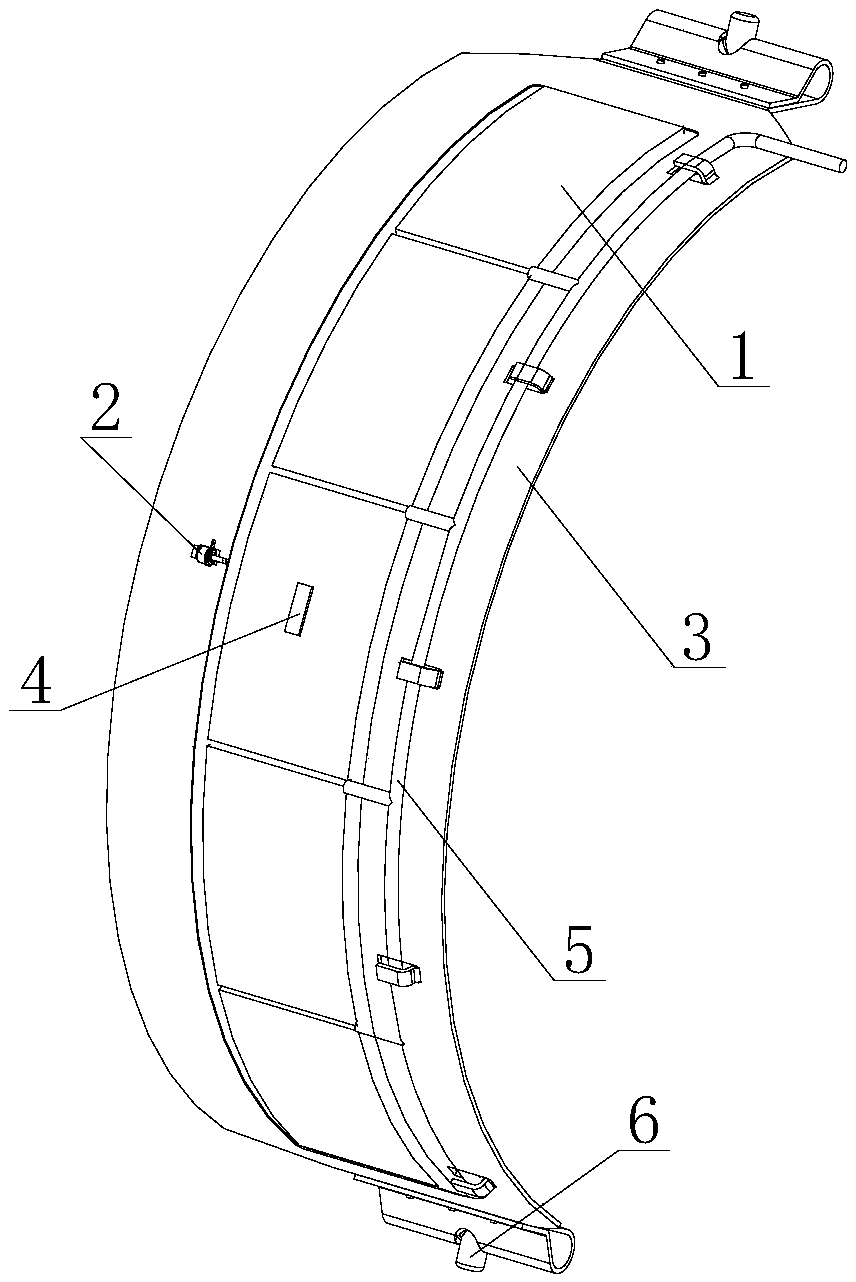

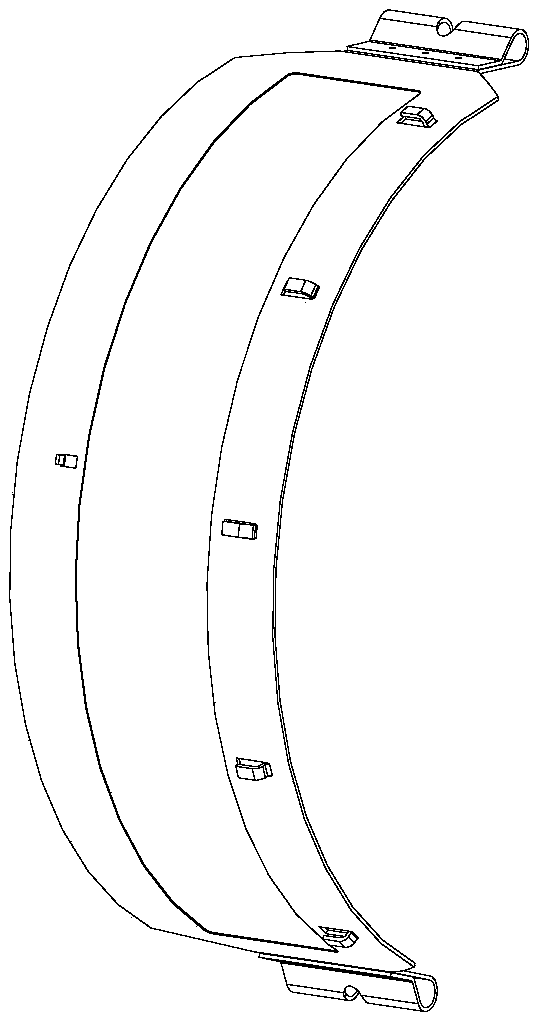

[0018] Such as figure 2 As shown, a heating device dedicated to an aircraft lubricating oil tank is provided, including a controller, a plurality of heating plates 1, a temperature relay 2, a housing part 3, a platinum resistor 4, a wire 5, and a sleeve 6.

[0019] In the heating device, the shell part 3 is an aluminum alloy material with good thermal conductivity; multiple heating plates 1 are evenly distributed on the shell part 3, and the shell part 3 is directly heated after being energized; the platinum resistor 4 is adhered to one of the heating plates 1, always detect the surface temperature of the heating plate 1, and convert the temperature signal into an electrical signal and transmit it to the controller; the temperature relay 2 is installed on the shell part 3, and when the platinum resistor 4 fails, it will replace it to monitor the temperature of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap