Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Natural mineral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

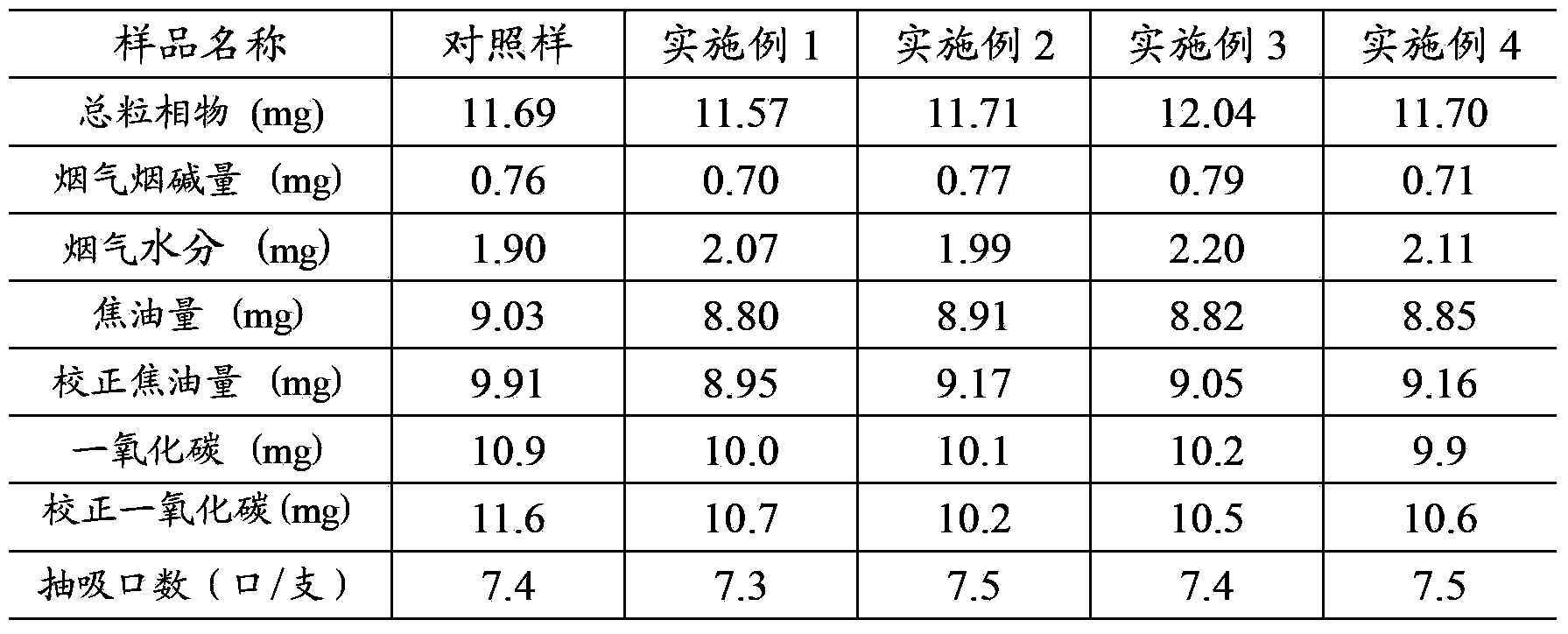

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Method for preparing alumina-based porous mineral material

ActiveCN102188950AImprove adsorption capacityLarge specific surface areaOther chemical processesWater/sewage treatment by sorptionKaoliniteWastewater

The invention discloses a method for preparing an alumina-based porous mineral material, which comprises the following steps of: grinding kaolinite with the purity of not less than 90 percent into 70 to 80 mass percent of fine particles with the particle size of -100 meshes; calcining the kaolinite fine particles at the high temperature of between 1,050 and 1,150 DEG C for 10 to 30 minutes; extracting silica from the calcined kaolinite by using 100 to 140g / L sodium hydroxide solution in a solid-liquid mass ratio of 1:8-1:12 at the temperature of between 90 and 140 DEG C for 90 to 120 minutes with stirring; and performing solid-liquid separation, and drying the obtained solid to obtain the alumina-based porous mineral material which has a good effect of adsorbing heavy metal ions in solution. The alumina-based porous mineral material prepared by the method is prepared from natural minerals with wide sources and large resource reserves, can be used for treating heavy metal ion polluted wastewater, and has a wide application prospect in the environment-friendly industry, and the preparation process is simple, and low in cost.

Owner:CENT SOUTH UNIV

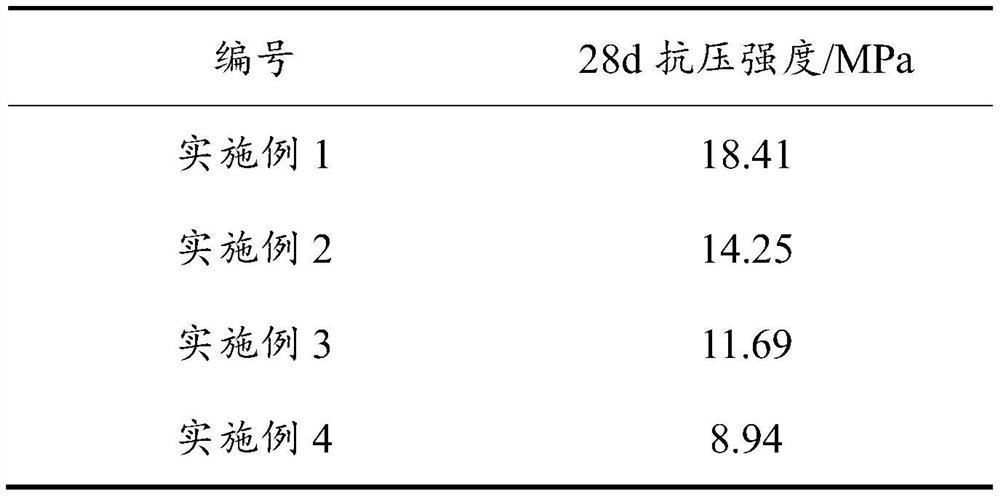

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

Blue-in-green rice-pattern glaze and application method thereof

ActiveCN107473589ABreak through the decorative effectNo side effectsClaywaresSilicon dioxideNatural mineral

The invention discloses a blue-in-green rice-pattern glaze and an application method thereof. The blue-in-green rice-pattern glaze is prepared from the following natural mineral raw materials and industrial chemical engineering raw materials in percentage by mass: 72.25 to 72.39% of SiO2 (silicon dioxide), 15.13 to 15.50% of Al2O3 (aluminum oxide), 0.71 to 0.73% of Fe2O3 (ferric oxide), 2.61 to 2.93% of K2O (potassium oxide), 1.23 to 2.22% of Na2O (sodium oxide), 6.64 to 6.93% of CaO (calcium oxide), and 0.28 to 0.45% of MgO (magnesium oxide) through proportioning, ball milling and screening. The blue-in-green rice-pattern glaze has the advantages that the blue-in-green decoration effect is realized without adding of oxide coloring agent, the decoration effect of the traditional rice-pattern porcelain in Jingdezhen is broken, most of raw materials are natural mineral raw materials, the sources are rich, the cost is low, any side effect to a human body is avoided, and the market space is broad.

Owner:JINGDEZHEN CERAMIC UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap