Surgical-instrument clamping mechanism, end effector and surgical mechanical arm with end effector

An end effector and surgical instrument technology, applied in the field of surgical robotic arms, can solve the problems of limited puncture range, tearing of the skin, and inability to move with breathing, etc., and achieve the effects of eliminating puncture point damage and eliminating trajectory deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

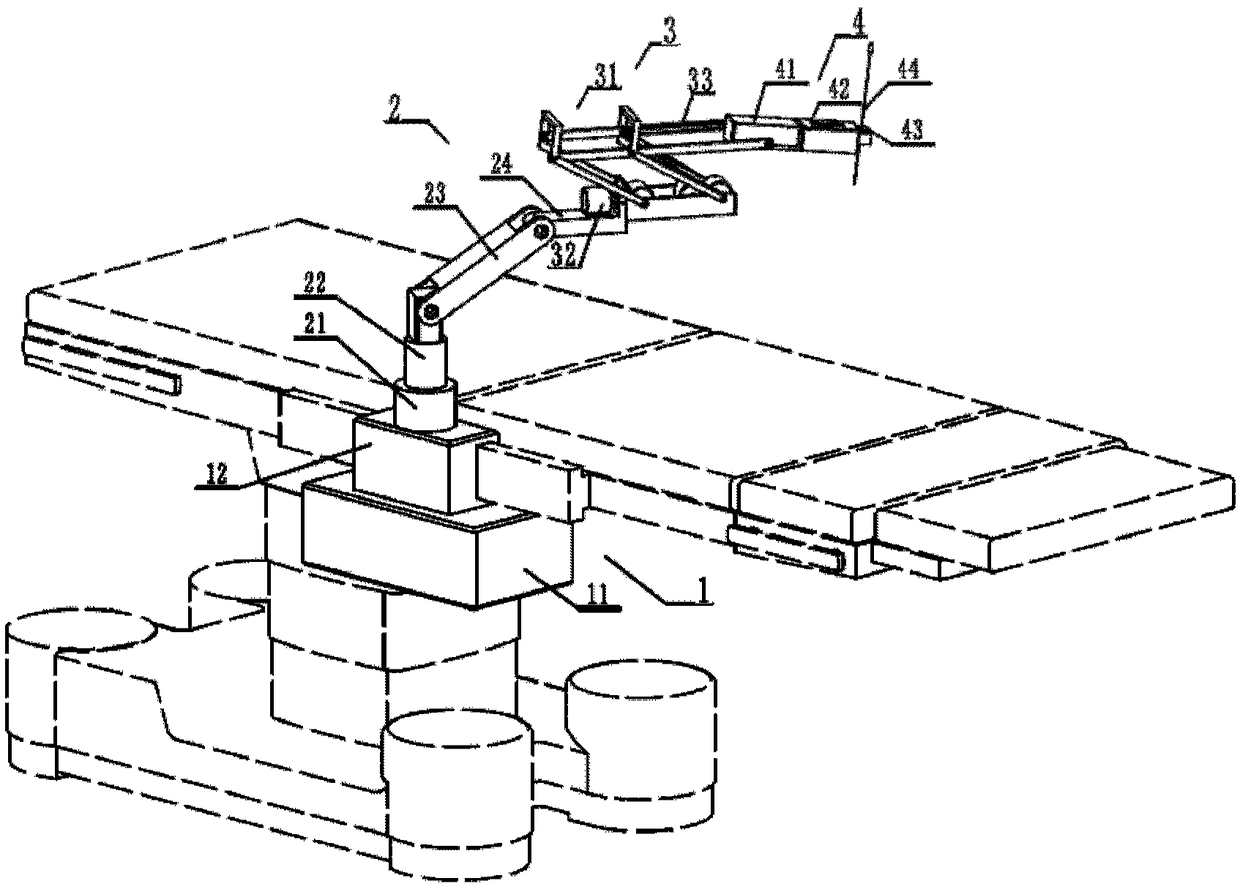

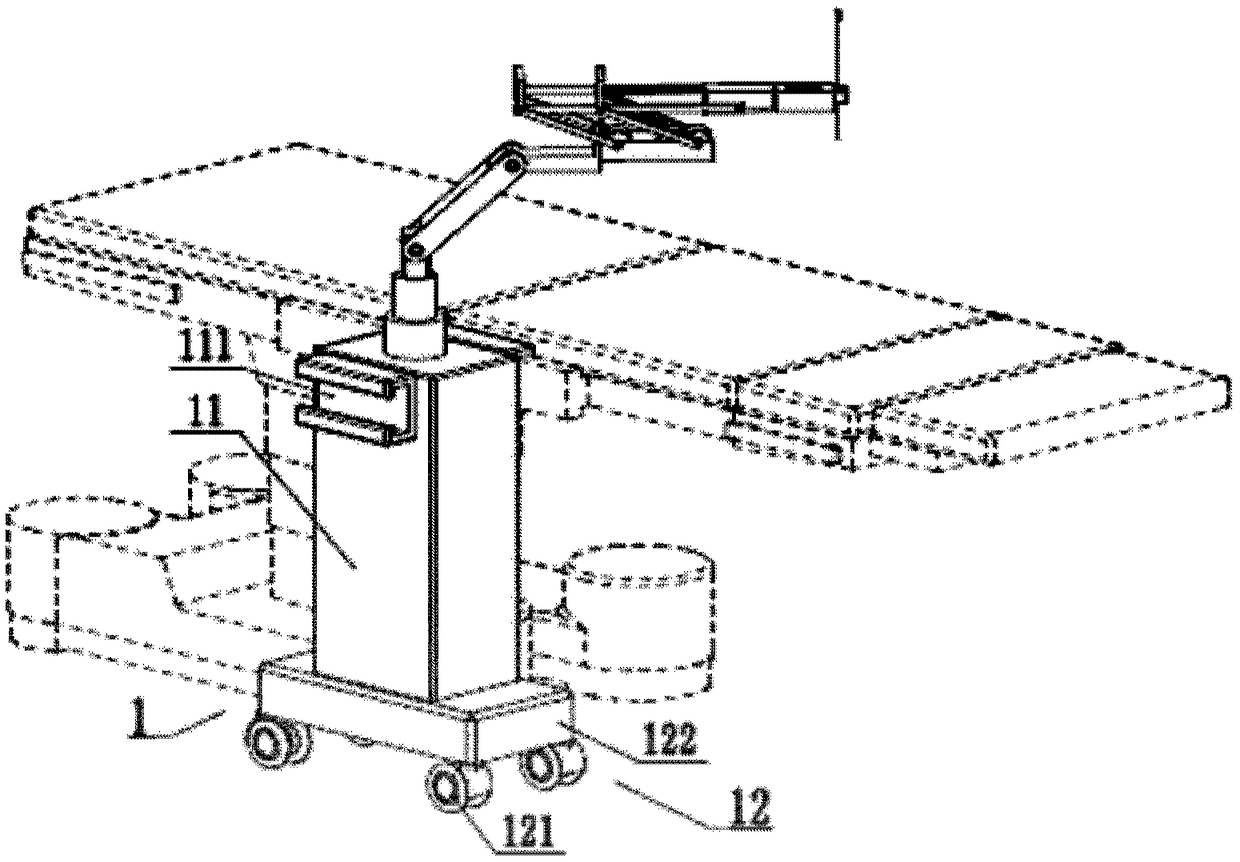

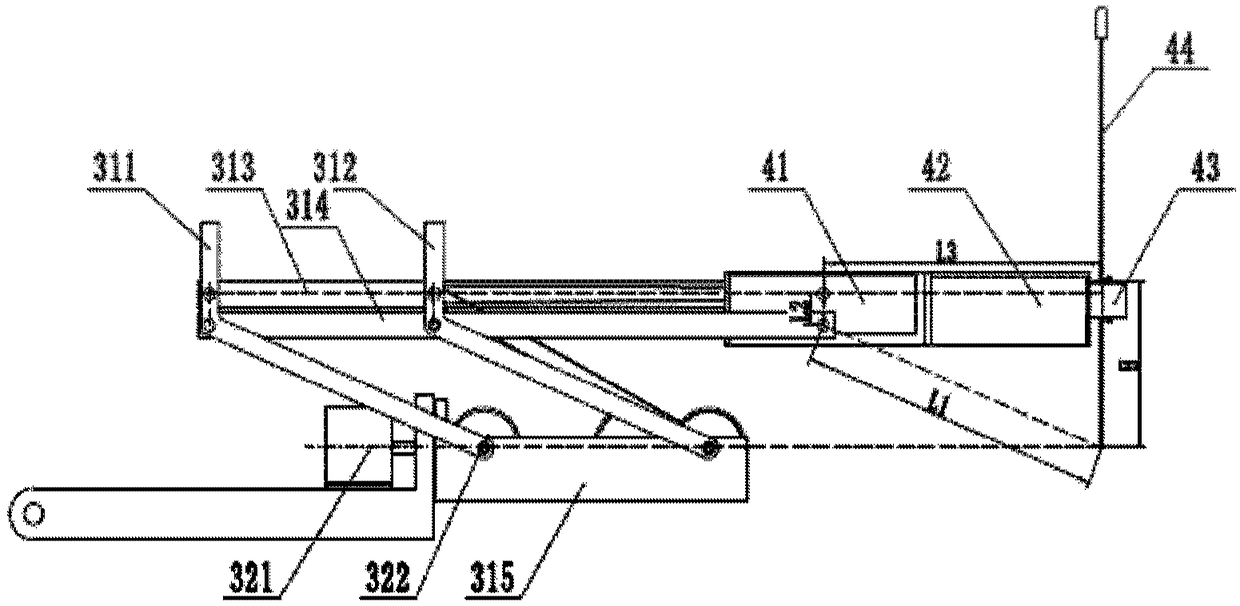

[0052]The invention discloses the structure and application of a slave end mechanical arm in a master-slave control medical robot system, which can realize various related percutaneous puncture actions, such as directional ablation, biopsy and the like. Under the guidance of real-time CT images, the robotic arm can be remotely controlled to adjust the puncture trajectory of surgical instruments (such as puncture needles and ablation needles), and guide the surgical instruments to advance along the target puncture trajectory to the target depth. At the same time, the surgical instrument feeding device at the end of the robotic arm can be disengaged from the robotic arm and can be re-engaged with the robotic arm. The detachmen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap