Novel spectacle material and production process thereof

A production process and new technology, applied in the field of sheet materials, can solve the problems of high axial strength and modulus, high price, small thermal expansion coefficient, etc., and achieve high axial strength and modulus, high cost and fatigue resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one: a kind of novel spectacle frame material, the production technology of its described material comprises the following steps:

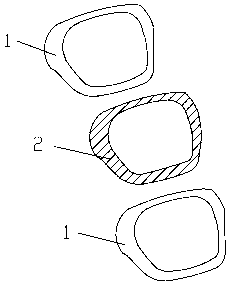

[0029] (1) Prepare materials: prepare the outer layer 1 and the inner layer 2 in advance, clean and dry them;

[0030] (2) Heat treatment: heat the outer layer plate 1 and the inner layer plate 2 to 60-120°C;

[0031] (3) Material bonding: apply glue on both sides of the inner sheet 2, then attach the two sides of the inner sheet 2 to the sheet respectively, and use a stamping laminating machine to press and fit to form a sandwich structure;

[0032] (4) Plate defoaming and lamination: Under a vacuum environment with a temperature of 70-120°C and an atmospheric pressure of 3-6G, use a high-temperature, high-pressure vacuum defoaming machine to perform compression lamination and defoaming treatment on the sandwich structure to form a sandwich plate;

[0033] (5) Bending forming: place the sandwich plate in the mold, and use the bend

Embodiment 2

[0036] Embodiment 2: A new type of spectacle frame material using carbon fiber material as the inner layer structure and resin plate material as the outer layer material. The production process of the material includes the following steps:

[0037] Prepare the outer sheet 1 made of resin material and the inner sheet 2 made of carbon fiber material in advance, clean and dry them respectively; heat the outer resin sheet 1 and the inner sheet 2 of carbon fiber to 60-120°C , according to the properties of the resin material and carbon fiber material, the temperature can be heated to 70-95°C as the best choice; apply glue on both sides of the carbon fiber inner layer plate 2, and then connect the two sides of the carbon fiber inner layer plate 2 with the resin outer layer plate respectively 1 for bonding, and use a stamping and laminating machine to press and fit to form a sandwich structure. The size of the inner sheet 2 to be bonded is the same as that of the outer sheet 1 or the inn

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap