Plate conveying device of plate punching equipment

A technology of punching equipment and conveying devices, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of difficult to guarantee the quality of punching, uneven levels of workers, and high labor intensity of workers. Achieve the effects of reducing labor intensity of workers, improving positioning accuracy, and improving punching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

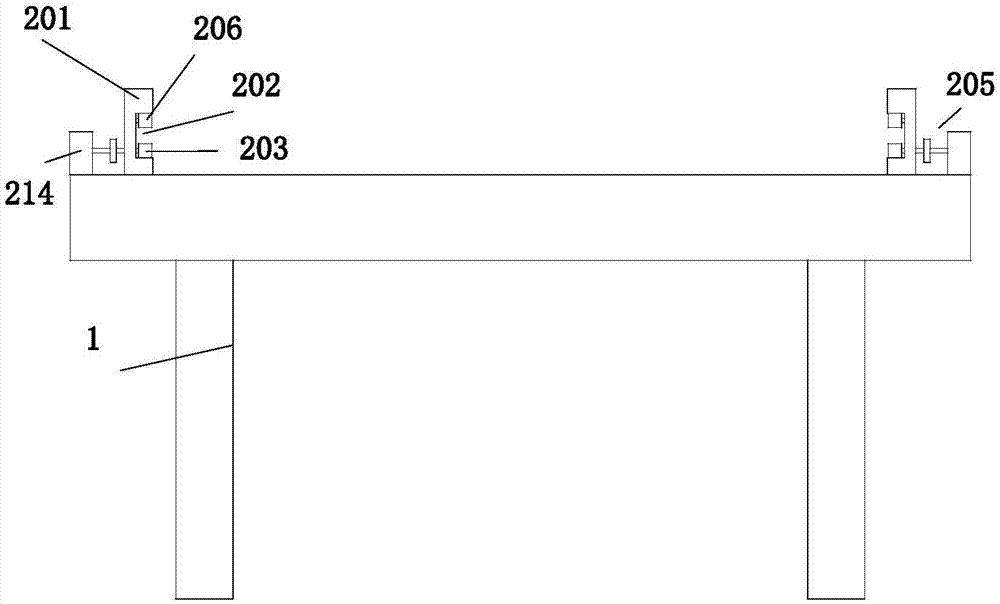

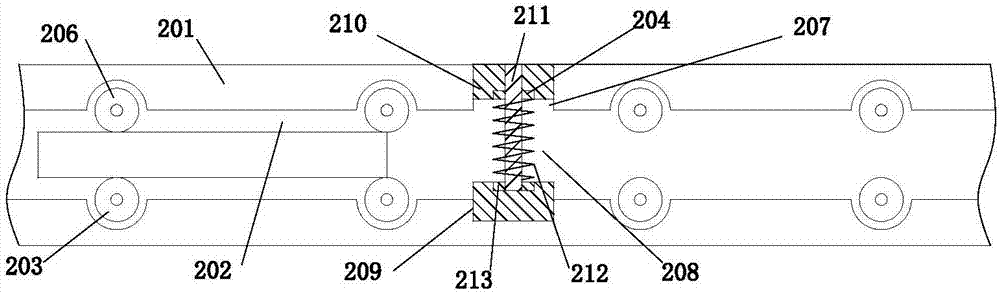

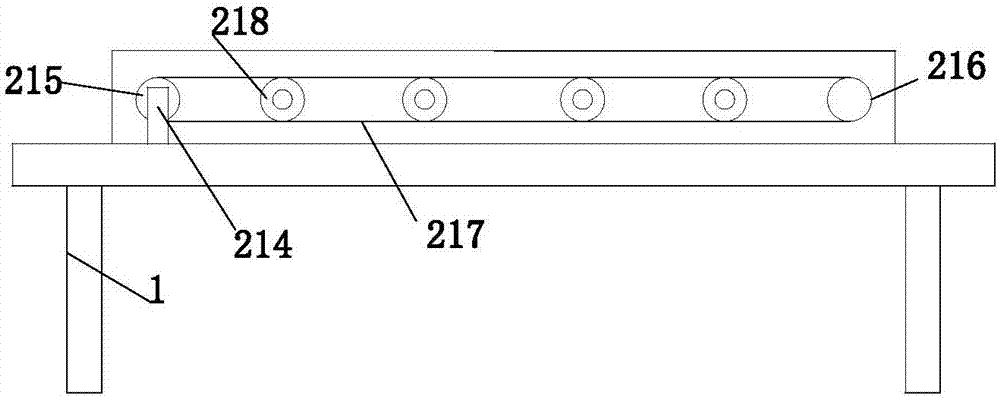

[0016] Example. A sheet material conveying device of sheet material punching equipment, constituted as figure 1 and Figure 4 As shown, including the frame 1, the frame 1 is provided with two guide rails 201 arranged in parallel front and rear, the inner surface of each guide rail 201 is provided with a chute 202, and the bottom end of the chute 202 is provided with a group of driving rollers 203, The top inside the chute 202 is provided with a group of driven pressing rollers 206; the driving roller 203 is connected with a chain drive mechanism 205 located on the outer side of the guide rail 201 via a rotating shaft; the chute 202 is also provided with a positioning opening 207 , the positioning opening 207 is provided with a positioning mechanism 208 .

[0017] The positioning mechanism 208 includ

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap