Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite reinforced multinutrition rice and process thereof

ActiveCN102067969AMeeting nutritional needsShorten soakFood preparationCALCIUM LACTOBIONATEGluconates

Owner:天津知味米有限公司

Method for optimizing cutting path of spacer frame type integral structural member

ActiveCN105069249AShorten the production cycleOptimize cutting pathForecastingSpecial data processing applicationsElement modelManufacturing technology

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Solder tip production process

ActiveCN104690513ARealize automatic processingFast processingSoldering bitsSoldering ironSewageCopper

Owner:陈爱华

Method for preparing GaN-based light emitting diode chip

ActiveCN104659165AReduce consumptionSimple processSemiconductor devicesTransparent conducting filmSolvent

The invention discloses a method for preparing a GaN-based light emitting diode chip. The method comprises the following steps: (1) growing a transparent conductive film on the surface of a P-type GaN layer; (2) manufacturing a conductive layer pattern of the transparent conductive film on the surface of the transparent conductive film; (3) pre-baking, removing moisture and a solvent on the surface of a GaN-based epitaxial wafer, and manufacturing a p-type GaN platform surface structure photoresist pattern; (4) etching a platform surface structure according to the pattern of the platform surface structure, and manufacturing a platform surface on an n-type GaN layer; (5) respectively preparing a p-type electrode and an n-type electrode on the platform surfaces of the transparent conductive film and the n-type GaN layer to obtain the GaN-based light emitting diode chip; (6) manufacturing a passivation layer on the surface of the GaN-based light emitting diode chip. By adopting the method, a step of removing photoresist after corrosion in an ordinary process is omitted, the process is simplified, the production period is shortened, the working efficiency is improved, and meanwhile the consumption of raw materials is reduced.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

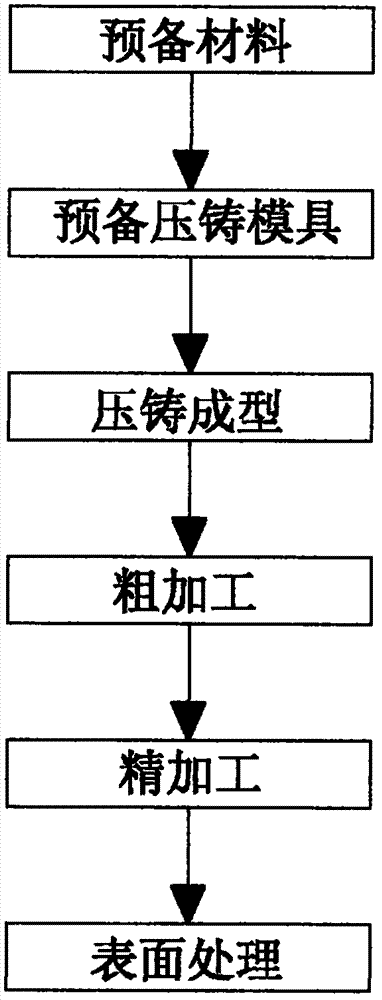

Aluminum alloy guide wheel manufacturing method and product thereof

InactiveCN107511640AImprove corrosion resistanceHigh structural densityAnodisationDie castingVolumetric Mass Density

Owner:邓南月

Autoclaved lime sand brick and production method thereof

InactiveCN104098312AStable expansion coefficientOvercome problemsSolid waste managementBrickMolding machine

The present invention discloses an autoclaved lime sand brick and a production method thereof, and solves the problems that in the prior art lime sand brick production cycle is long, the intensity is not high, the discrete degree is great and the like; the autoclaved lime sand brick is characterized in that: on the traditional basis of green sand and quick lime, a right amount stone chip is added, the quick lime is crushed, then the quick lime, the green sand and the stone chip are firstly mixed with water in an ash mixing machine, after 2.5 ~ 3 hours of hopper type digestion, secondary stirring is performed to make caking in the mixture broken and loose, the mixture is sent by a conveying system into a turntable type molding machine for pressing into green bricks, the pressed green bricks are sent by a traction machine into an autoclave for high temperature and high pressure autoclaving to produce the autoclaved lime sand brick with the strength more than 2 times of that of national standard of ordinary standard bricks.

Owner:HUANGGANG TONGKAI BUILDING MATERIALS CO LTD

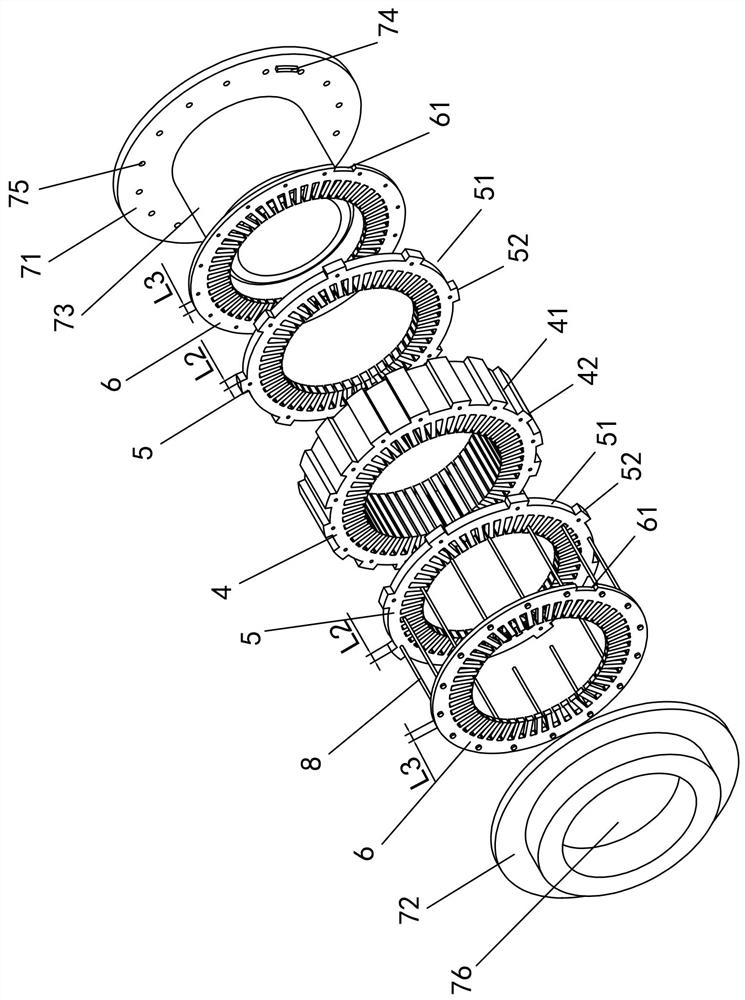

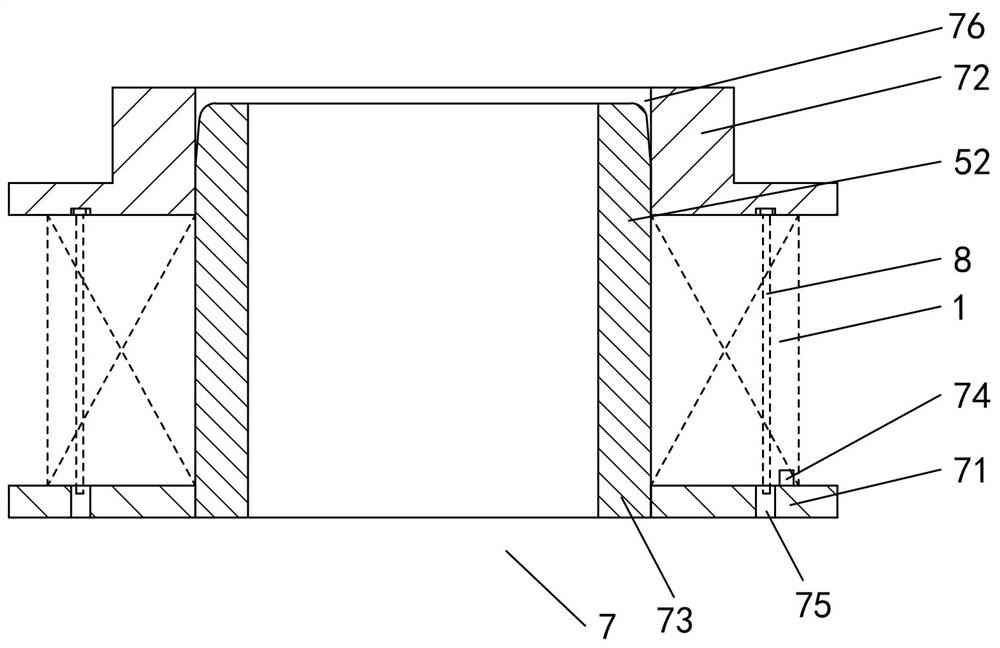

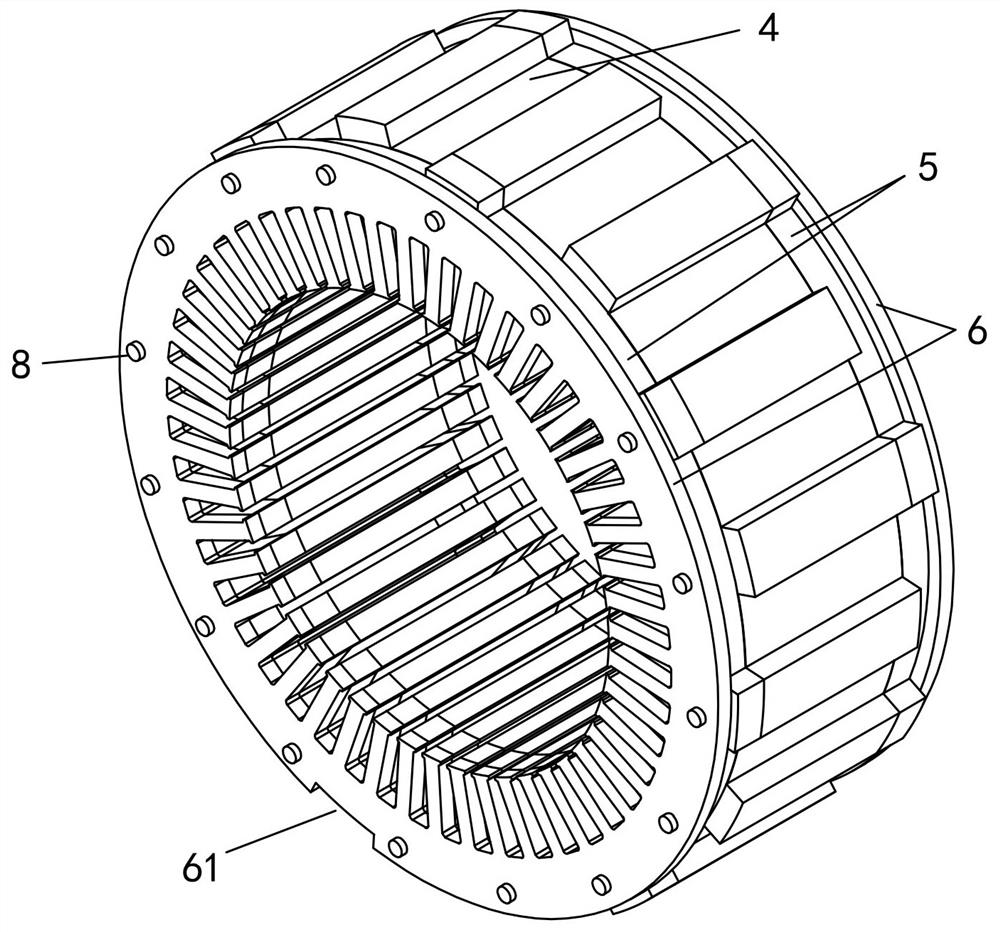

Manufacturing method of stator of oil-cooled motor

ActiveCN112104171AMagnetic circuit stationary partsManufacturing stator/rotor bodiesProduction cycleThermodynamics

Owner:KINETEK DE SHENG SHUNDE MOTOR CO LTD

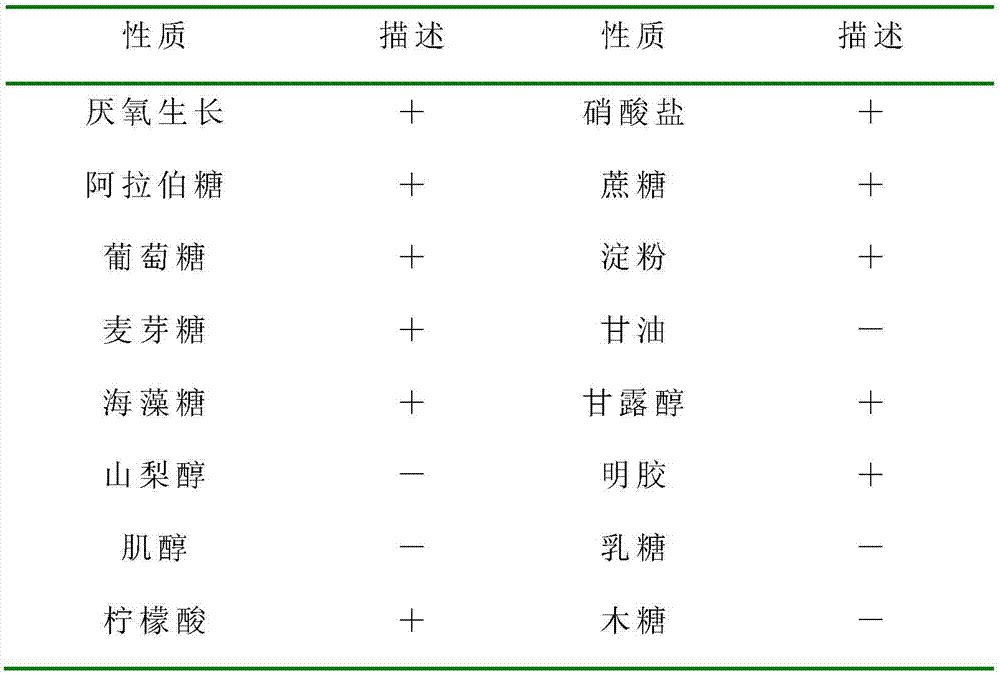

Technology for preparing biopesticide by compounding bacillus cereus and antibiotic

InactiveCN107094797AImprove survival rateHigh antibacterial efficiencyBiocideDead animal preservationBacillus cereusCulture mediums

Owner:NANJING UNIV OF TECH

Injection-extrusion integration forming method for transparent parts edge enhancement

ActiveCN107672135AGood light transmissionHigh precisionDomestic articlesTemperature controlHigh intensity

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

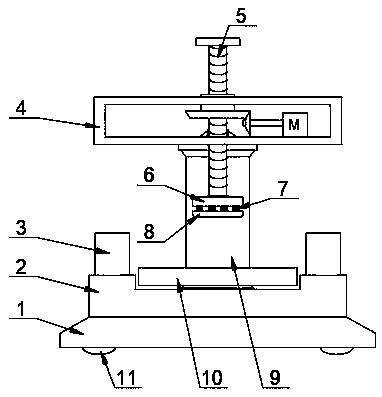

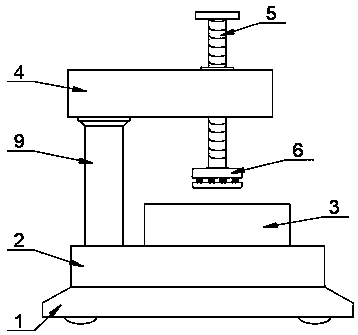

Cutting die processing device and cutting die automatic processing technology

ActiveCN102699177ASolve the defect that the cutting method of the olecranon at the front and rear ends of the mold cannot be realized automaticallyFast processingCutleryEngineeringMachining time

Owner:深圳同致精工技术有限公司

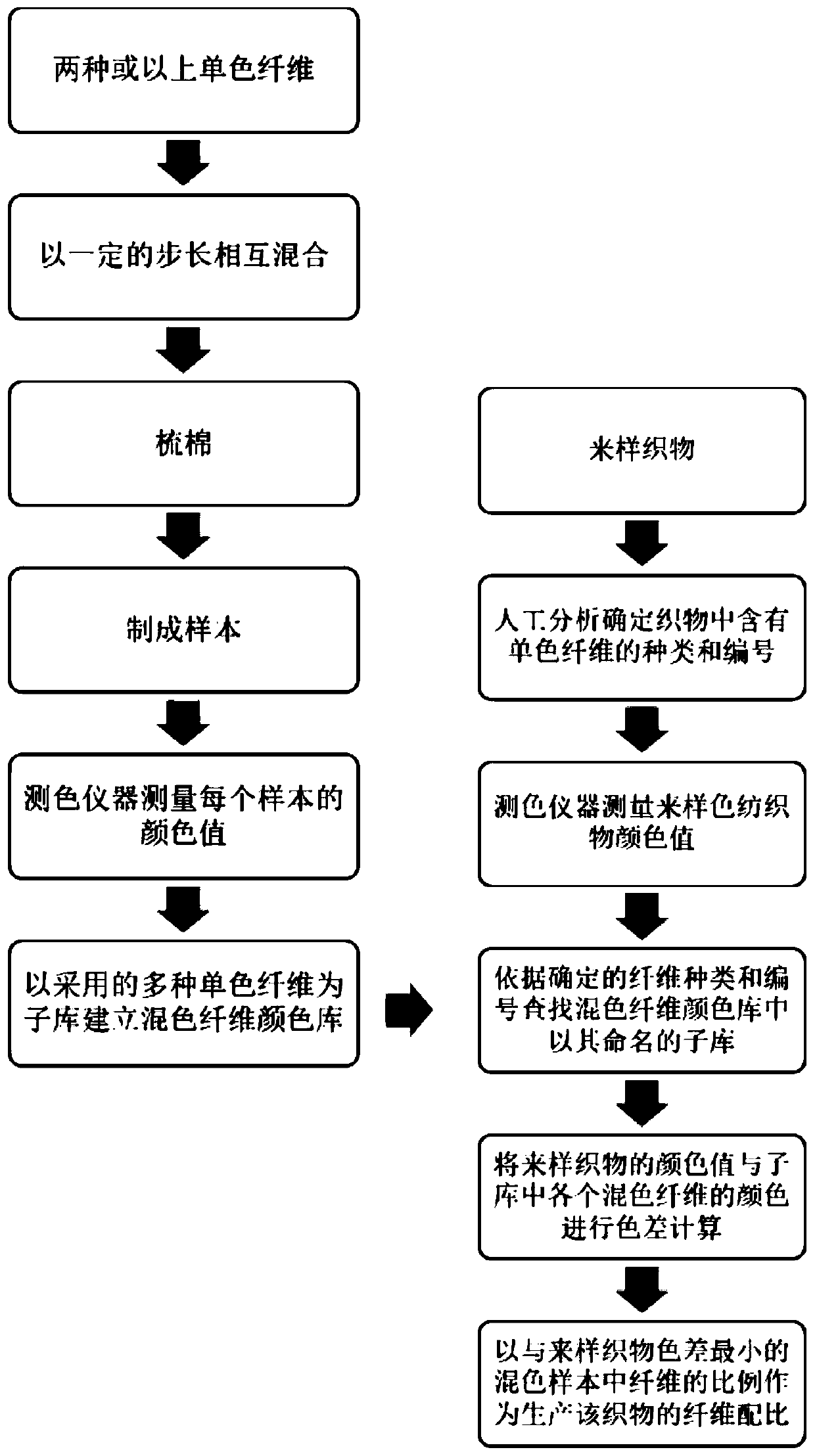

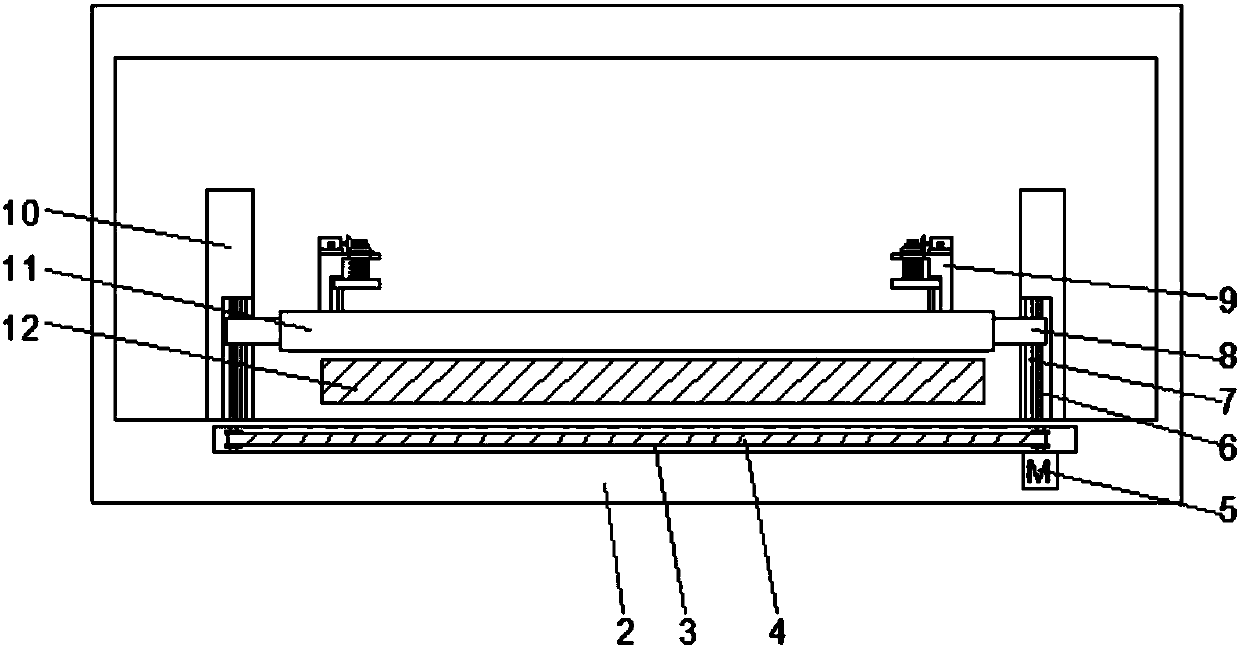

One-step color matching method for color-spun fabric

InactiveCN109813431AAccurate and convenient color matching methodThe color matching method is simple and straightforwardColor measuring devicesPattern recognitionCarding

Owner:ZHEJIANG HUAFU COLOR TEXTILE +1

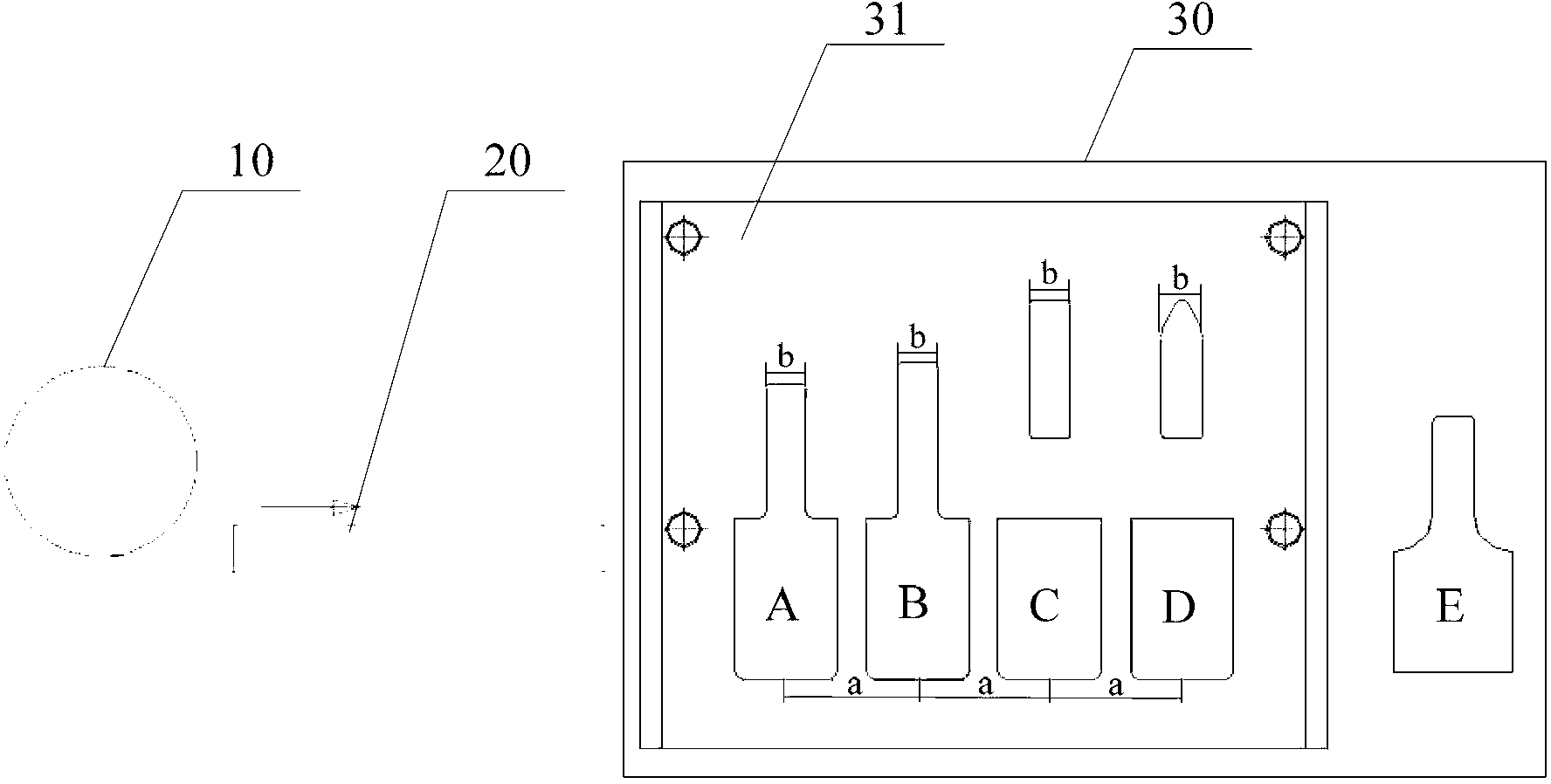

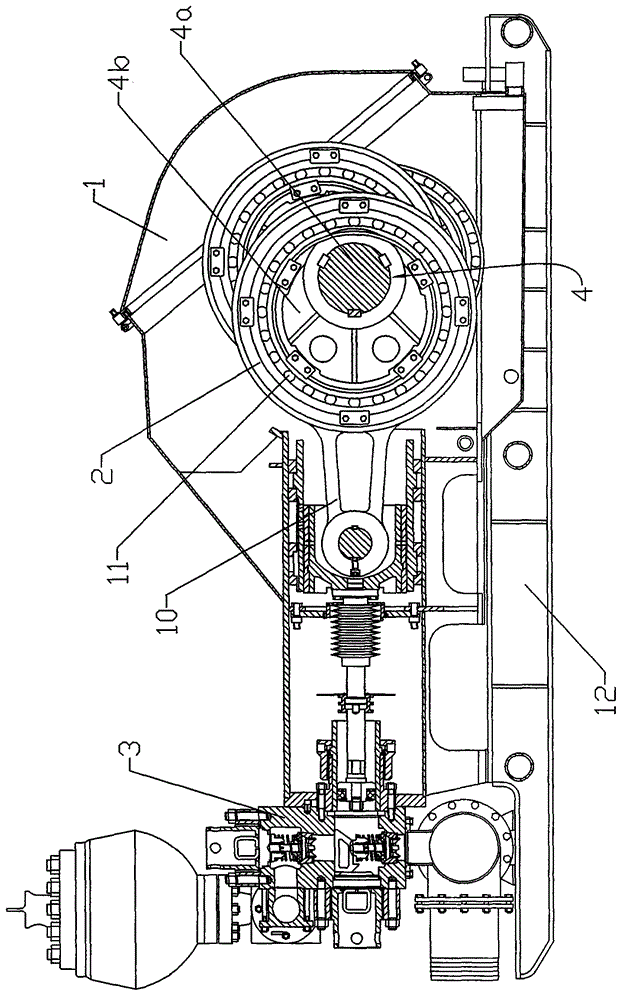

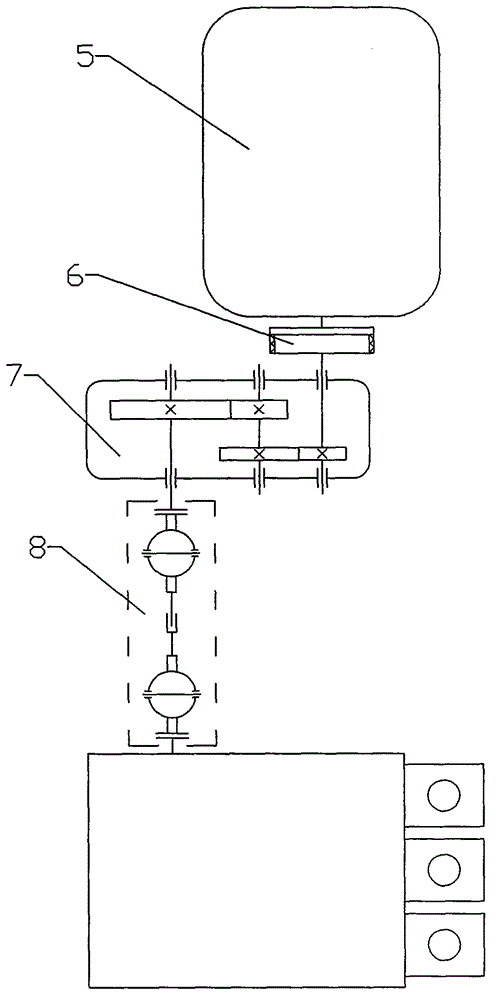

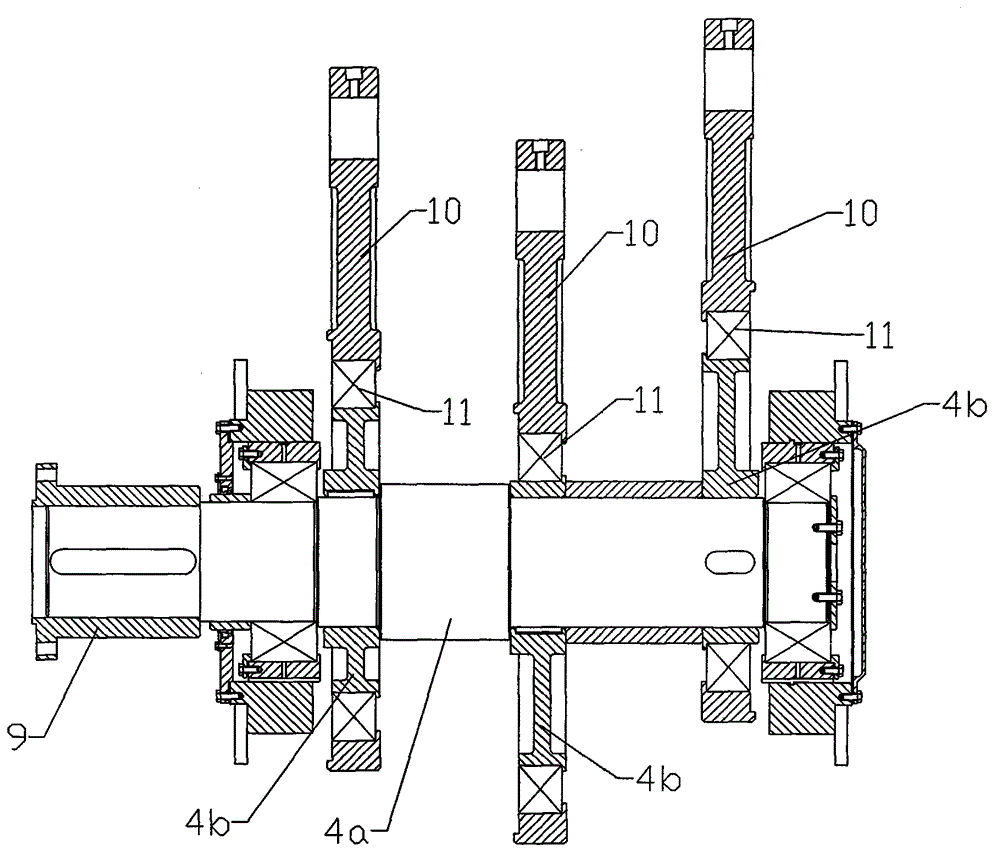

Wound core clamping part fixing device

Owner:海泉风雷新能源发电股份有限公司

Energy-saving brick produced by sludge of sewage treatment plant and preparation method thereof

InactiveCN107162544ASolve resource problemsReduce secondary pollutionBuilding componentsProduction rateBrick

The invention belongs to the technical field of building materials, and provides an energy-saving brick produced by sludge of a sewage treatment plant and a preparation method thereof. The energy-saving brick produced by sludge of the sewage treatment plant is prepared from, by weight, 42-56 parts of sludge of sewage treatment plant, 12-16 parts of Chinese herbal medicine, 6-19 parts of quick lime, 6-13 parts of oyster powder, 1-7 parts of early strength agent, 1.05-3.07 parts of water reducing agent, 3-15 parts of flame retardant, and 7-18 parts of water. The invention aims to provide the energy-saving brick produced by sludge of the sewage treatment plant, and the energy-saving brick solves the problem of sludge resource; the preparation method of the energy-saving brick produced by sludge of the sewage treatment plant has advantages of reducing production cycle, being free from sintering and heat energy, saving time, improving the production yield, and reducing production cost; more importantly, the preparation method can relieve the secondary pollution caused by improper sludge disposal.

Owner:ANHUI KEHUI UNITED CERTIFICATION CO LTD

Novel precious metal packaging mechanism

Owner:江苏华邑市政工程有限公司

Novel metal compounding process

InactiveCN105313422AHarm reductionHigh strengthLaminationLamination apparatusExplosive claddingMetallic materials

The invention discloses a novel metal compounding process. The process comprises the following steps of: (1) performing surface roughening treatment to ensure that the surfaces of bonding layers are dissolved and roughened; (2) preparing a complex, namely adding an interlayer metal material with low melting point and high electric conductivity between substrate-layer metal and composite-layer metal so as to ensure that the interlayer metal material is permeated between the substrate-layer metal and the composite-layer metal to form metallurgical bonding; and (3) rolling the complex on a roller mill so as to closely bond the substrate-layer metal and the composite-layer metal. According to the process, an explosive cladding link is eliminated in a production environment, so that the harm of explosive cladding to the environment is reduced; the production cost is saved, and the production cycle is shortened; and moreover, the welding and rolling of all bonding surfaces are combined, so that the bonding compactness is relatively high.

Owner:匡永刚

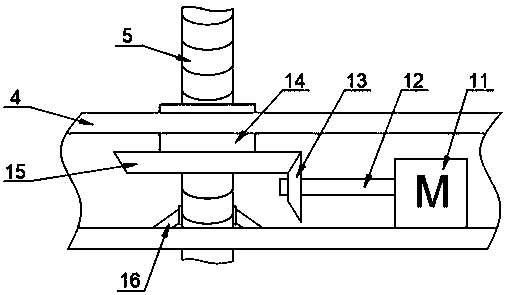

Drilling pump used for drilling

InactiveCN104454430AReduce processing stepsShorten the production cyclePiston pumpsPositive-displacement liquid enginesWell drillingReducer

Owner:闫晖

Fresh rhizoma gastrodiae freeze-dried cakes and making method thereof

InactiveCN110013012AEliminate drying processAlleviate storage difficultiesFood preservationAdditive ingredientMedicine

Owner:SICHUAN CHIJIAN TRADITIONAL CHINESE MEDICINE TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap