Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Surface roughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

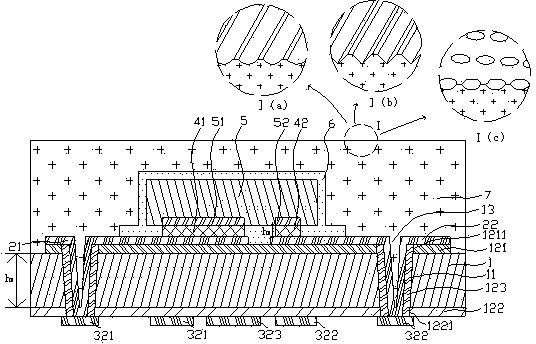

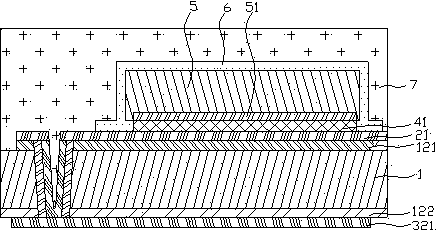

Wafer-level packaging method of semiconductor device

ActiveCN104465973ASmall sizeIn line with the trend of miniaturizationSolid-state devicesSemiconductor devicesInsulation layerDevice material

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

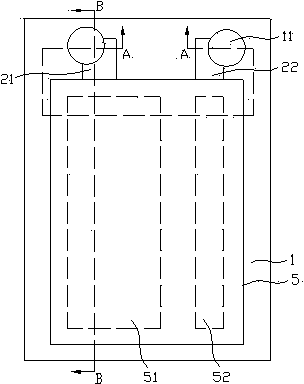

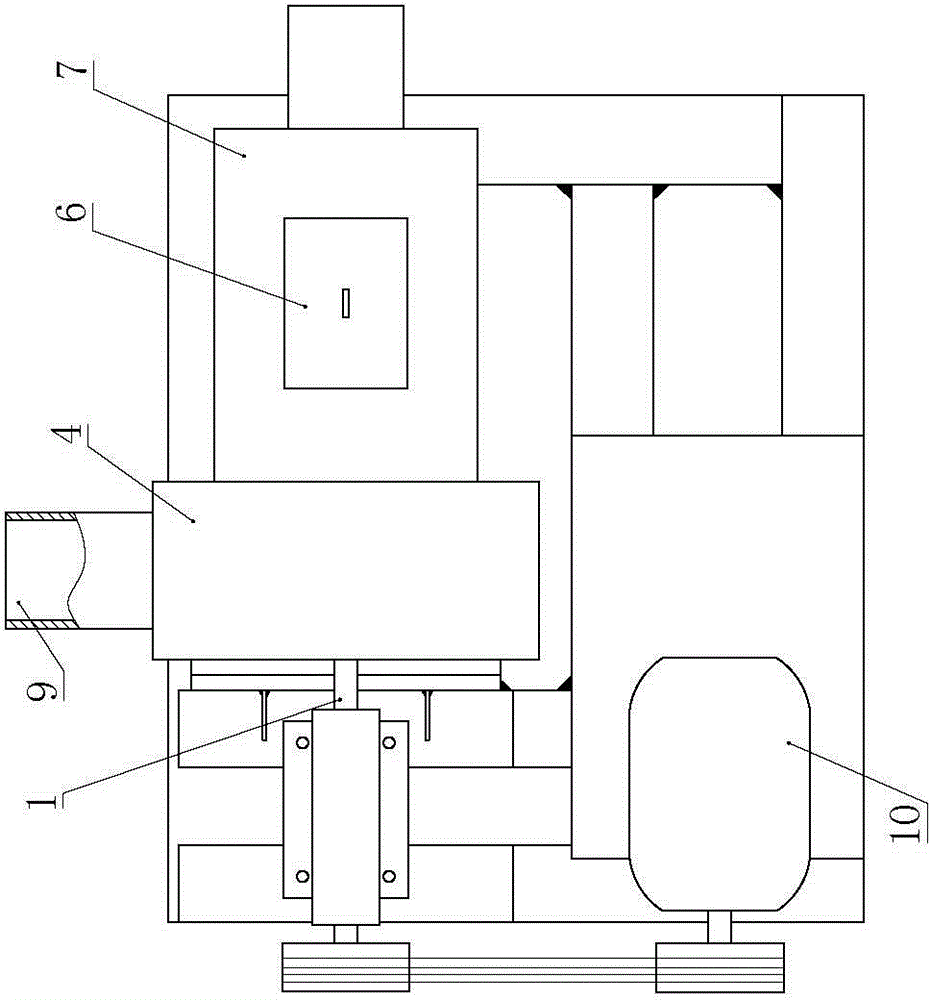

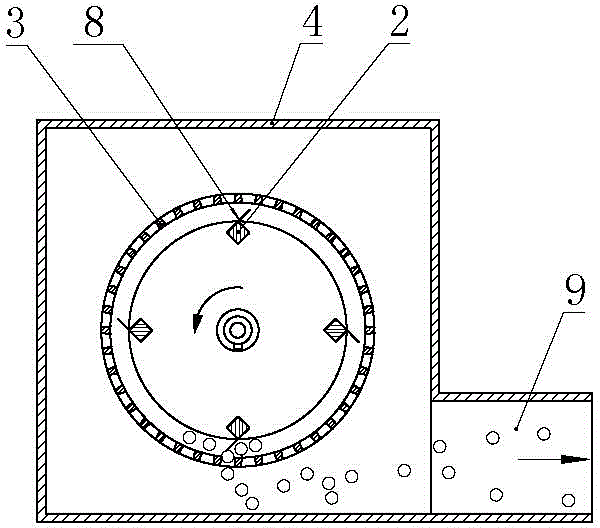

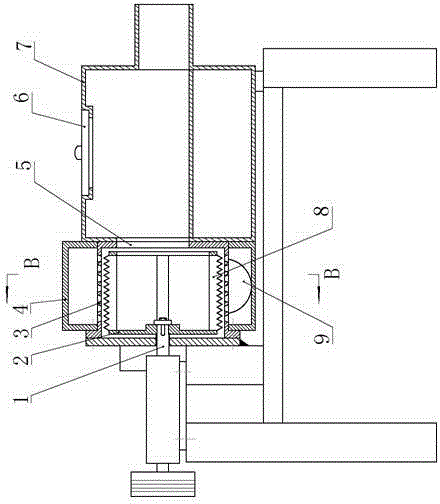

Treatment machine for increasing surface roughness of plastic foam particles

InactiveCN104690954ASmooth entryStir wellRough surfaceSuction force

Owner:LONGKOU ZHENGREN ENERGY SAVING BUILDING MATERIALSEQUIP MFG

Novel metal compounding process

InactiveCN105313422AHarm reductionHigh strengthLaminationLamination apparatusExplosive claddingMetallic materials

The invention discloses a novel metal compounding process. The process comprises the following steps of: (1) performing surface roughening treatment to ensure that the surfaces of bonding layers are dissolved and roughened; (2) preparing a complex, namely adding an interlayer metal material with low melting point and high electric conductivity between substrate-layer metal and composite-layer metal so as to ensure that the interlayer metal material is permeated between the substrate-layer metal and the composite-layer metal to form metallurgical bonding; and (3) rolling the complex on a roller mill so as to closely bond the substrate-layer metal and the composite-layer metal. According to the process, an explosive cladding link is eliminated in a production environment, so that the harm of explosive cladding to the environment is reduced; the production cost is saved, and the production cycle is shortened; and moreover, the welding and rolling of all bonding surfaces are combined, so that the bonding compactness is relatively high.

Owner:匡永刚

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap