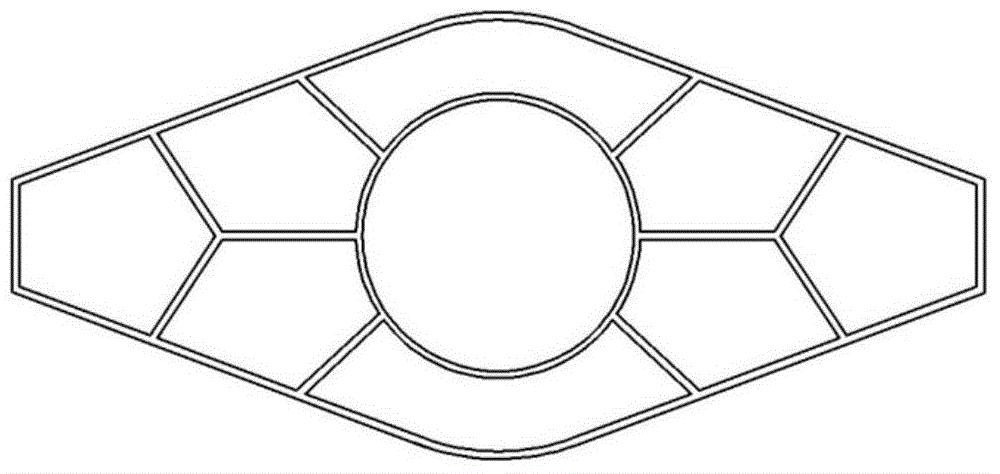

Method for optimizing cutting path of spacer frame type integral structural member

A technology of integral structural parts and structural parts, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of less research on cumulative processing deformation, shorten production cycle, control processing deformation, improve processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The method of optimizing cutting path based on dynamic cutting simulation will be described in detail below.

[0040] (1) Dynamic cutting simulation method

[0041] In the process of finite element simulation analysis, in order to dynamically simulate the cutting process of materials and the change of local stiffness of parts in real time, "element life and death technology" is needed. "Element life and death" means that in the area where the workpiece material is about to be removed, the area is divided into grids and the grid units are deleted within a specific time (a certain analysis step). Any rigidity, so that the units to be cut can be removed step by step according to the specified order according to the cutting path. In the process of simulating workpiece material removal, not only the material to be removed should be removed in the form of unit life and death, but also the corresponding cutting force should be applied to the surface of the removed material to si

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap