Automatic carrying device for luggage case shells

A case and equipment technology, which is applied in the field of automated transport equipment for cases, can solve problems such as increased production costs, gaps in the quality and accuracy of finished products, and inconvenience in production and use, so as to ensure the processing accuracy of finished products, shorten production cycles, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings:

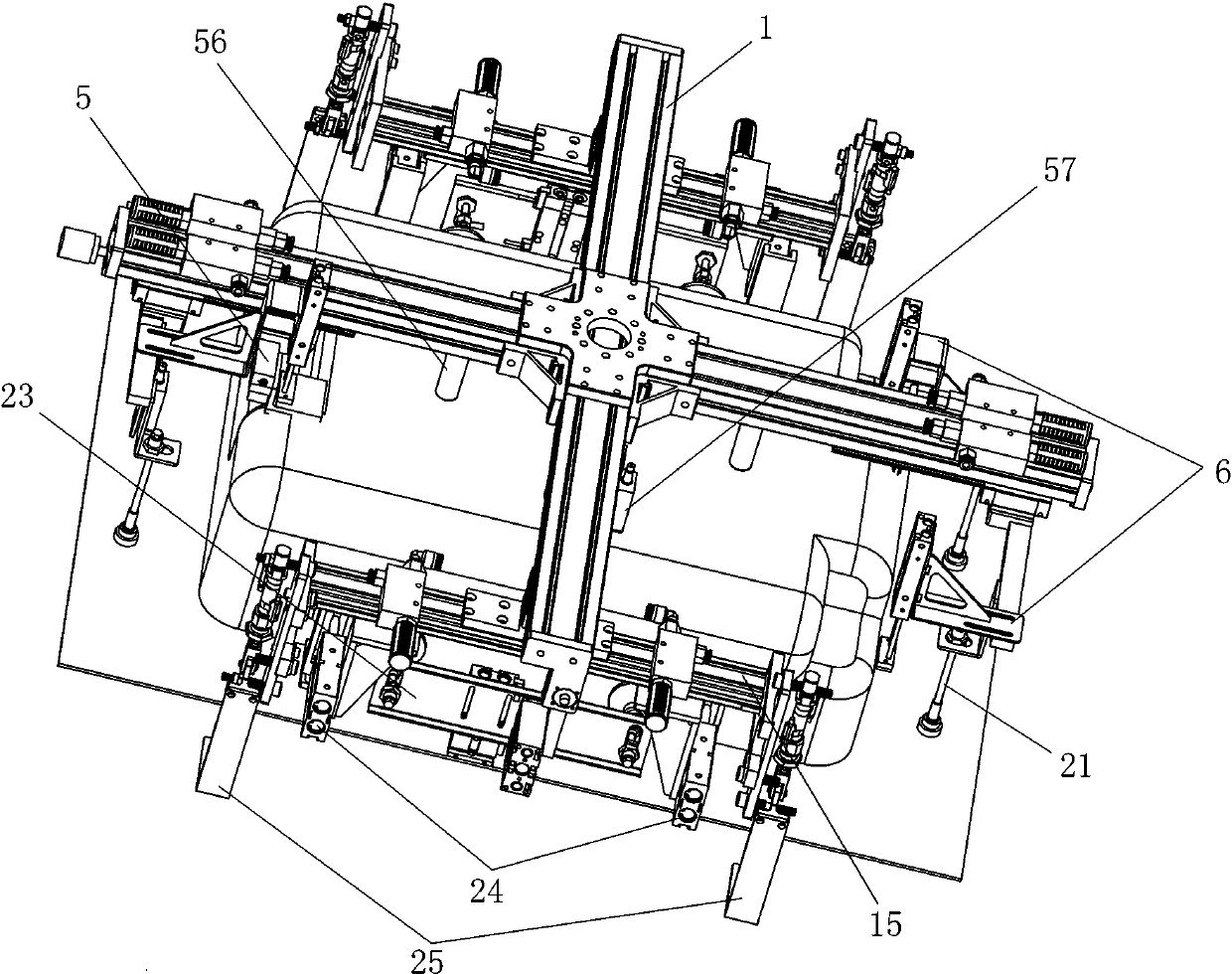

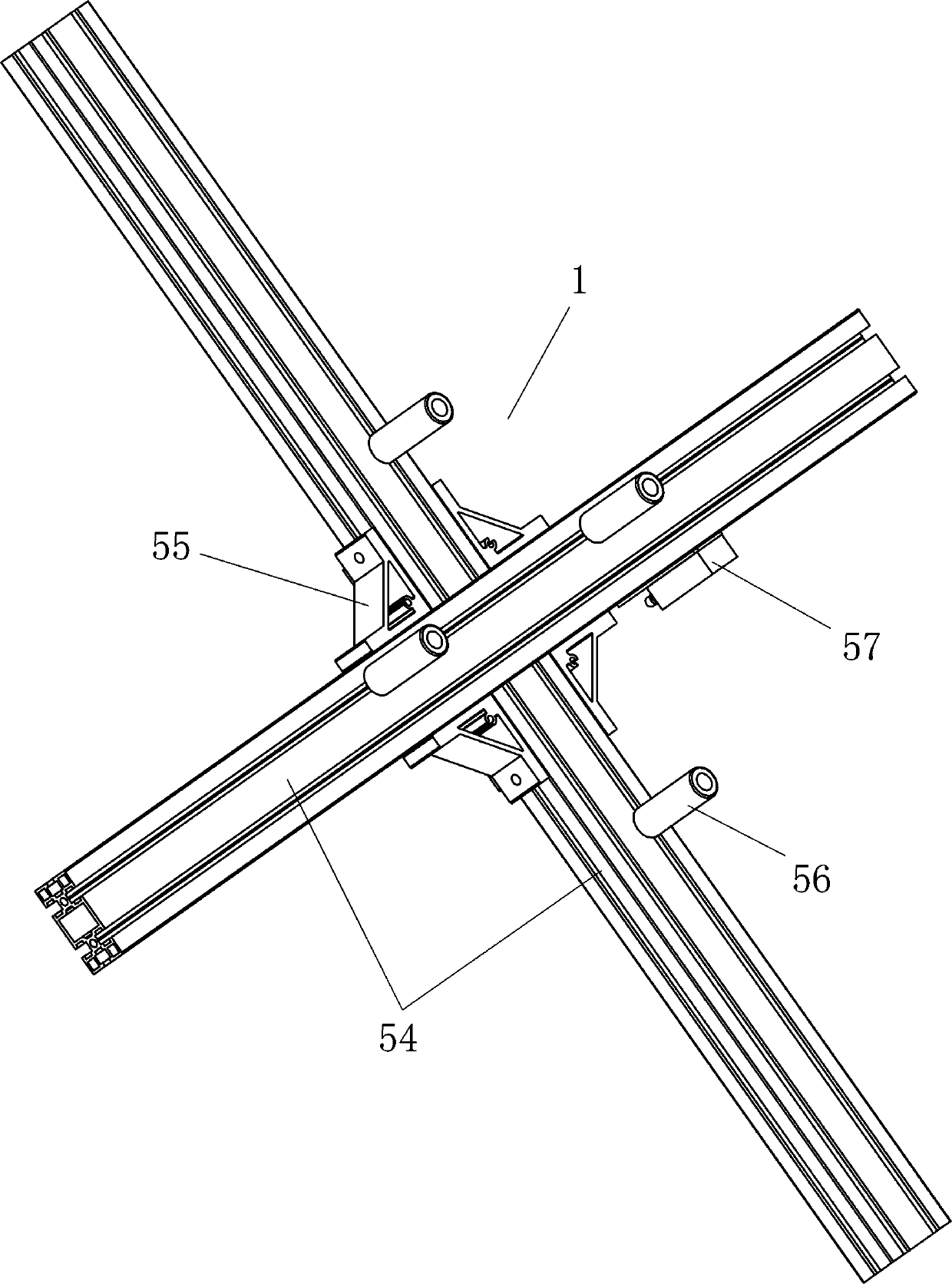

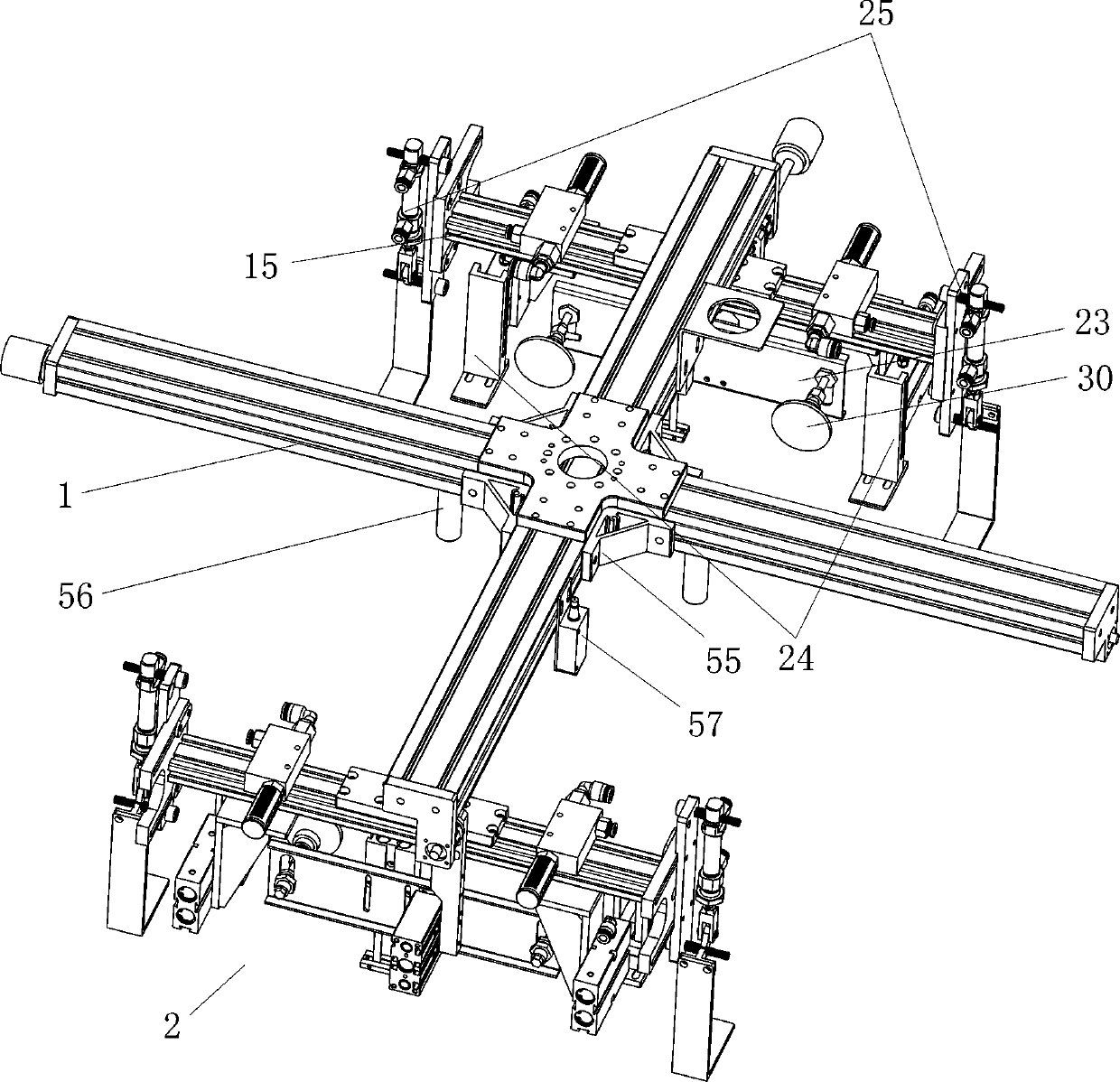

[0032] Such as Figure 1-12 As shown, an automated carrying equipment for a box casing includes a bracket 1, a clamping device 2 and a detection device 3. The clamping device 2 and the detection device 3 are mounted on the bracket 1, and the clamping device 2 includes two sets of grasping mechanisms 4, the two sets of grasping mechanisms 4 are adjustablely installed on the front and rear sides of the bracket 1 at a certain interval, and the detection device 3 includes a rod position detection mechanism 5 and a caster position detection The mechanism 6, the rod position detection mechanism 5 and the caster position detection mechanism 6 are respectively adjustable on the left and right sides of the bracket 1 at a certain distance.

[0033] Wherein, the bracket 1 is provided with a first adjustment mechanism 7 and a second adjustment mechanism 8. The first adju

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap