Process and apparatus for the polymerisation of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

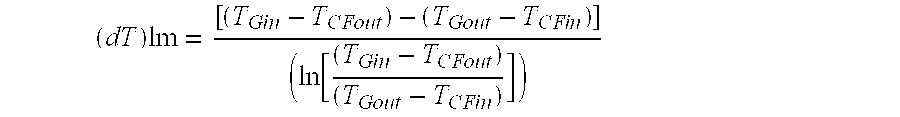

Image

Examples

Embodiment Construction

[0017]In contrast, the present Applicants have now been able to operate a polymerisation process which is characterised by negligible fouling rates, even though some fine particles are present in the recycle stream. Such processes do not require shut-down to clean heat exchangers, even after several years of operation.

[0018]Thus, in a first aspect the present invention provides a process for the gas phase polymerisation of olefins in a fluidised bed reactor, which process comprises:[0019]a) passing a fluidising gas comprising one or more olefin monomers through a fluidised bed of polymer particles in the presence of a polymerisation catalyst,[0020]b) withdrawing a first gaseous stream comprising solid particles from the top of the reactor,[0021]c) passing the first gaseous stream to a gas / solids separator, separating solid particles therefrom, and forming a second gaseous stream comprising residual solid particles,[0022]d) passing at least a portion of the second gaseous stream to on

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Velocity | aaaaa | aaaaa |

| Velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap