Full-automatic coffee screen cloth forming device

A coffee mesh and fully automatic technology, applied in metal processing, etc., can solve the problems of low production efficiency and high defective rate, and achieve the effect of improving productivity, reducing production cost and defective rate, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

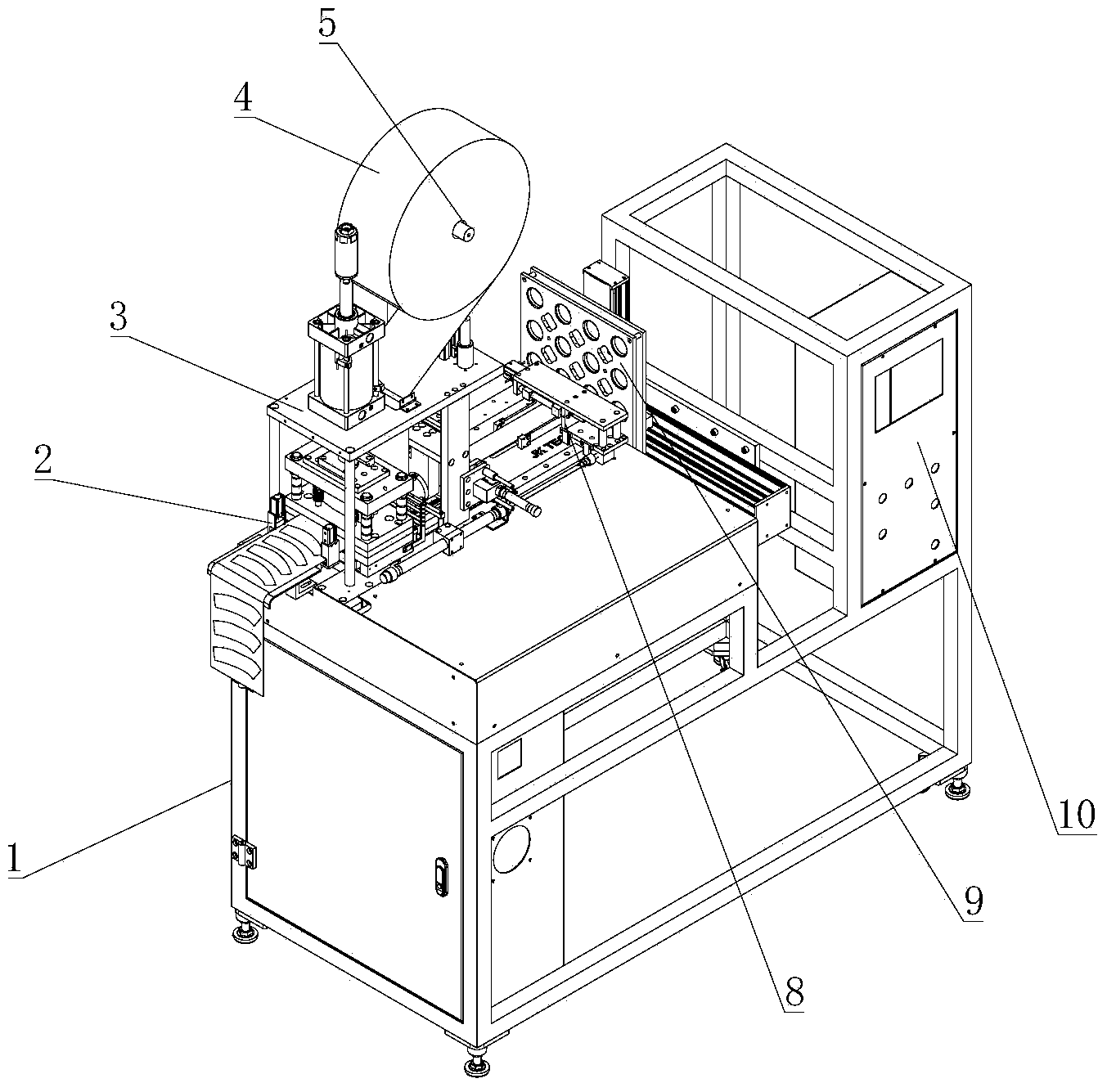

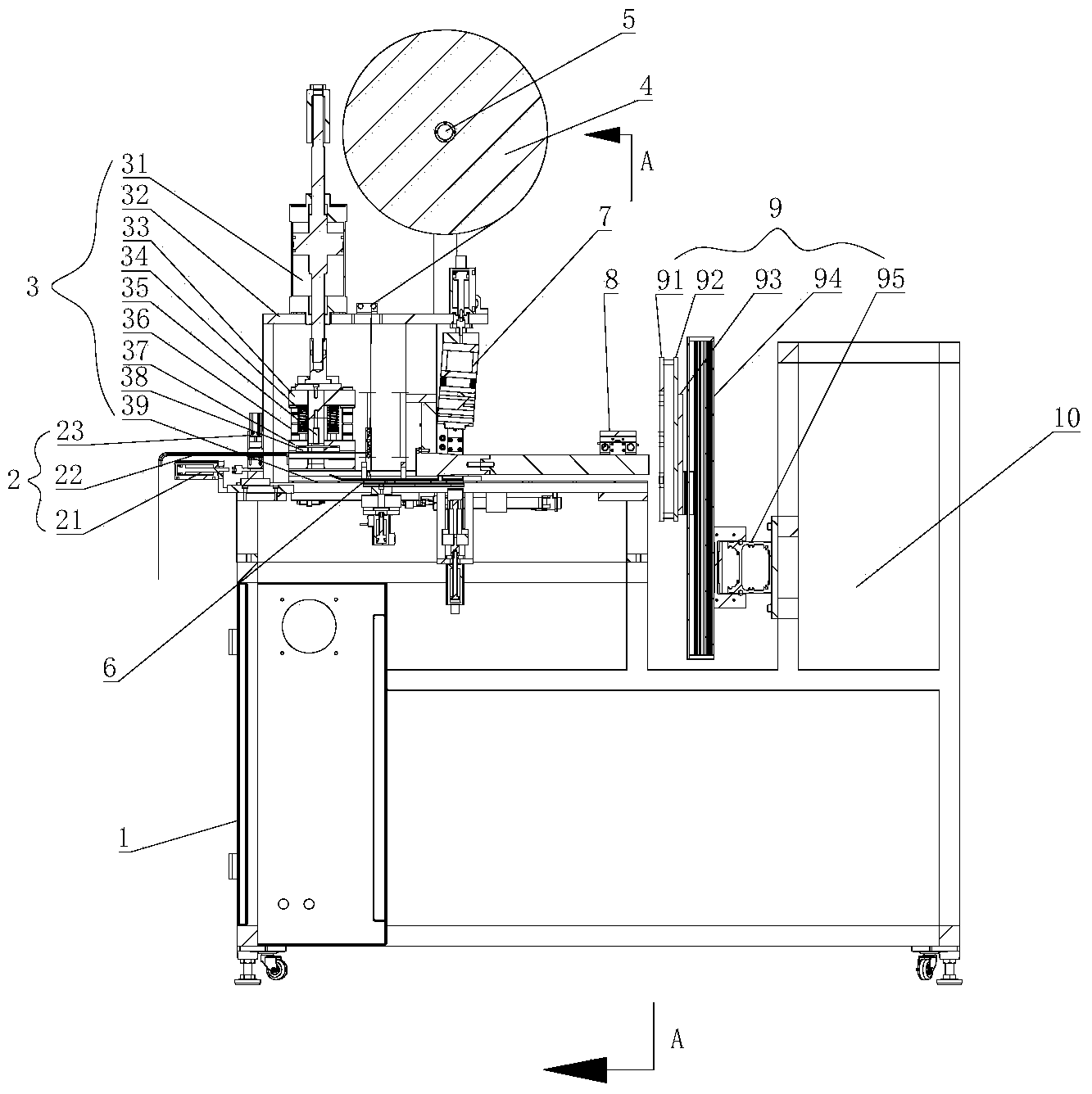

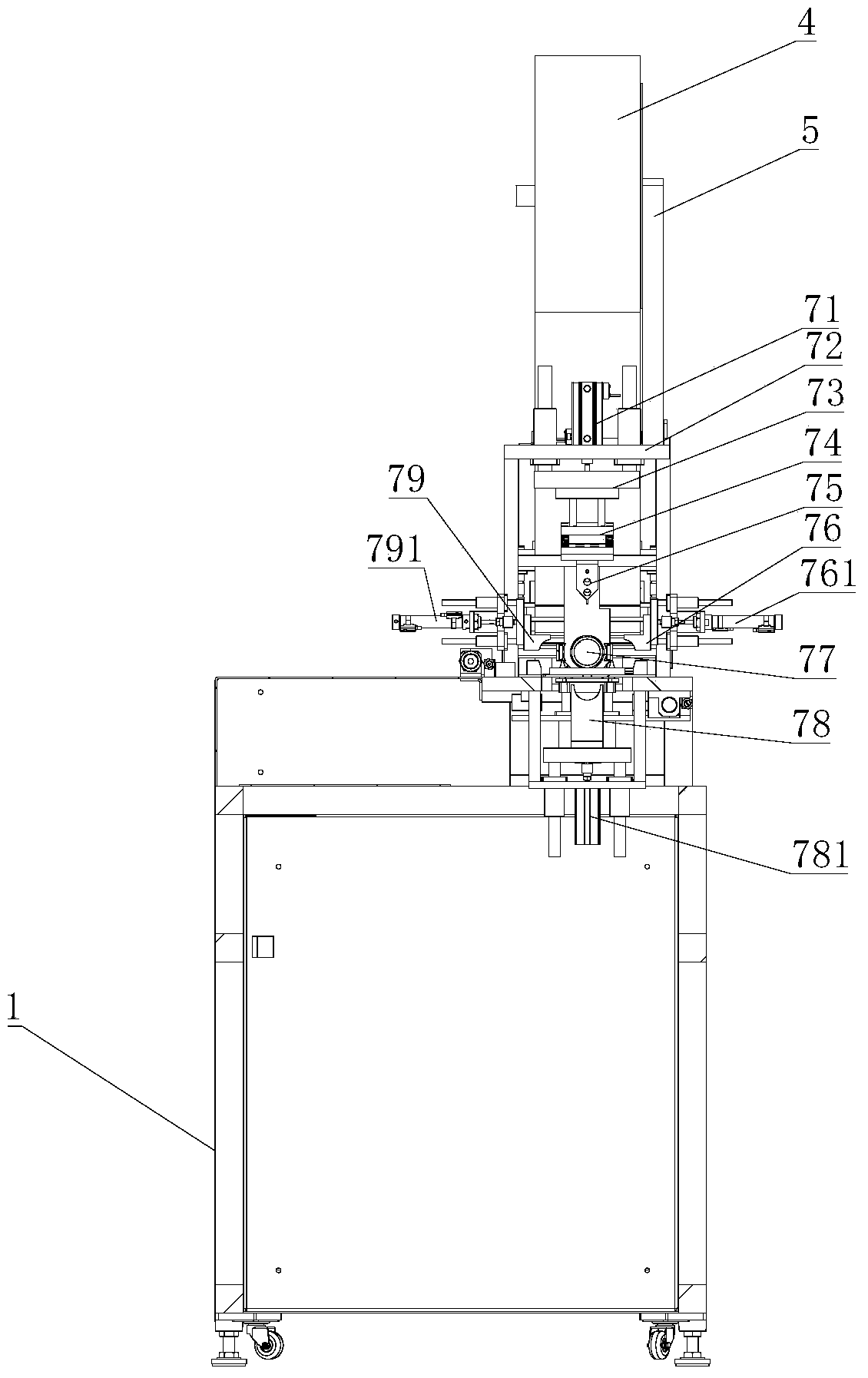

[0034] Such as Figure 1 to Figure 9 As shown, the fully automatic coffee mesh forming device of the present invention respectively defines the coffee mesh before punching as the mesh raw material, the blanking after punching as the coffee mesh, and the welded coffee mesh as the mesh The ring includes a frame 1, a material placement mechanism arranged on the frame 1, a punching mechanism 3 for punching mesh raw materials, a pulling mechanism 2 for conveying mesh raw materials to the punching mechanism, and a The transport mechanism 6 for the coffee mesh to the next process, the welding forming mechanism for welding the coffee mesh into a ring shape 7, the demoulding mec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap