Downhole/openhole anchor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

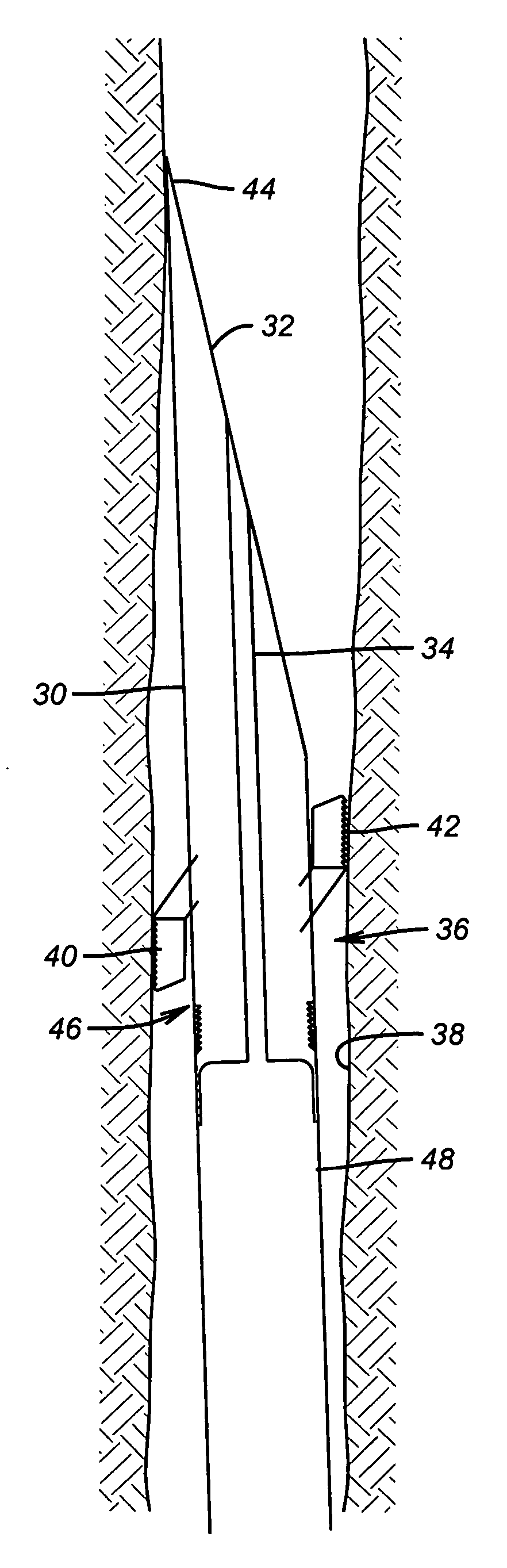

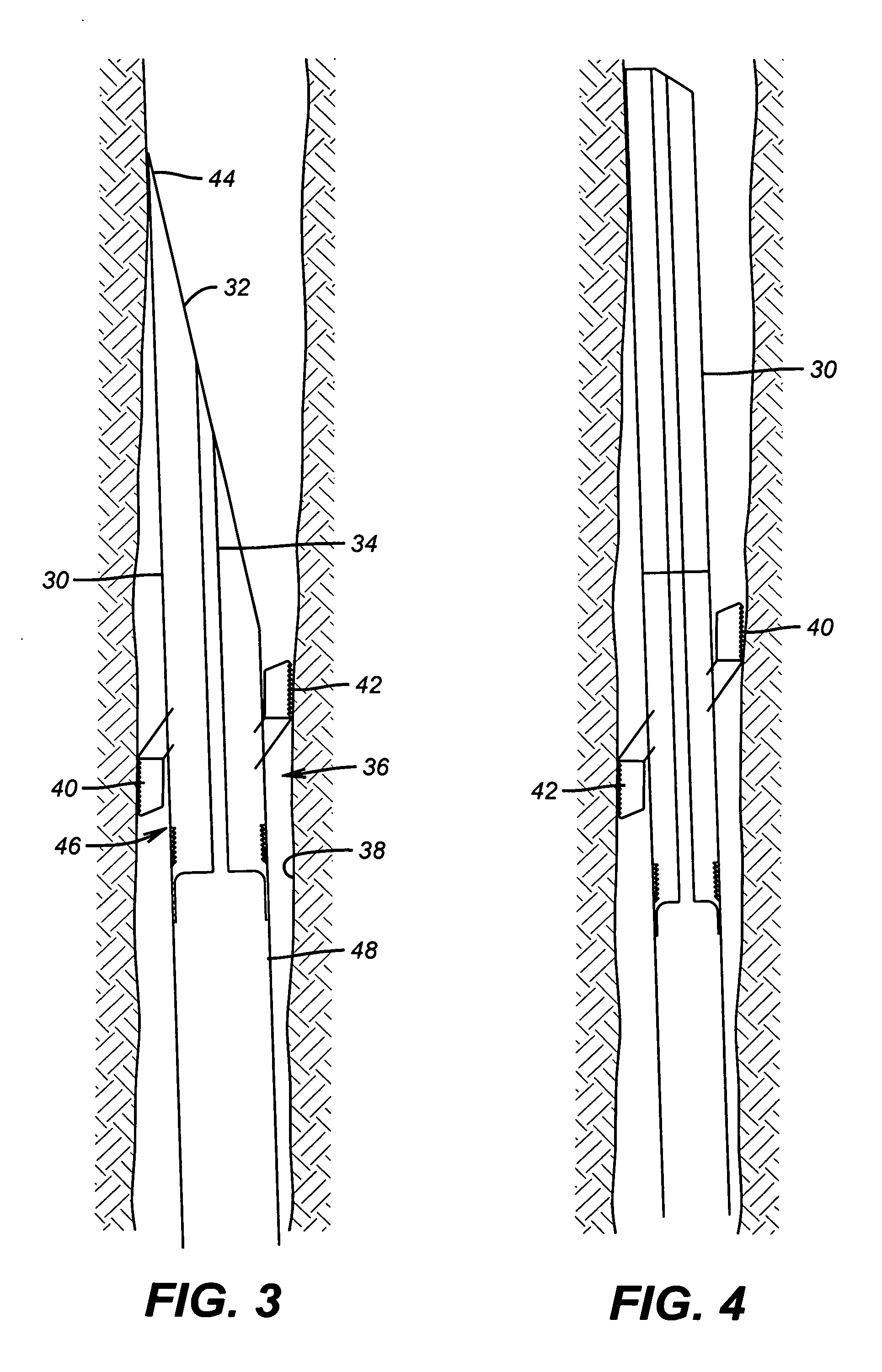

[0015] The overall assembly is best seen in FIG. 3. There a whipstock / billet 30 has a tapered face 32 and a through passage 34 through which a setting tool (not shown) is initially extending for setting the anchor 36 in borehole 38. Anchor 36 preferably has lower slip sets 40 of which only one is shown and at least one upper slip set 42. Preferably when there are two slip sets 40 and an upper slip set 42 the circumferential spacing among them is preferably about 120 degrees. This puts the lower slip sets 40 on one side of the anchor 36 with the upper slip set 42 on the other. In fact the angles of separation can vary with the idea being that the lower slips sets being on one half of the circumference and the upper slip sets on the other. The reason for this will be explained below.

[0016] Looking again at FIG. 3, showing the anchor 36 now set, it can be seen that the upper end 44 of the whipstock / billet 30 is pushed against the borehole 38. This happens when lower slip sets 40 push

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap