Stable wood planing assembly of a veneer wood planing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

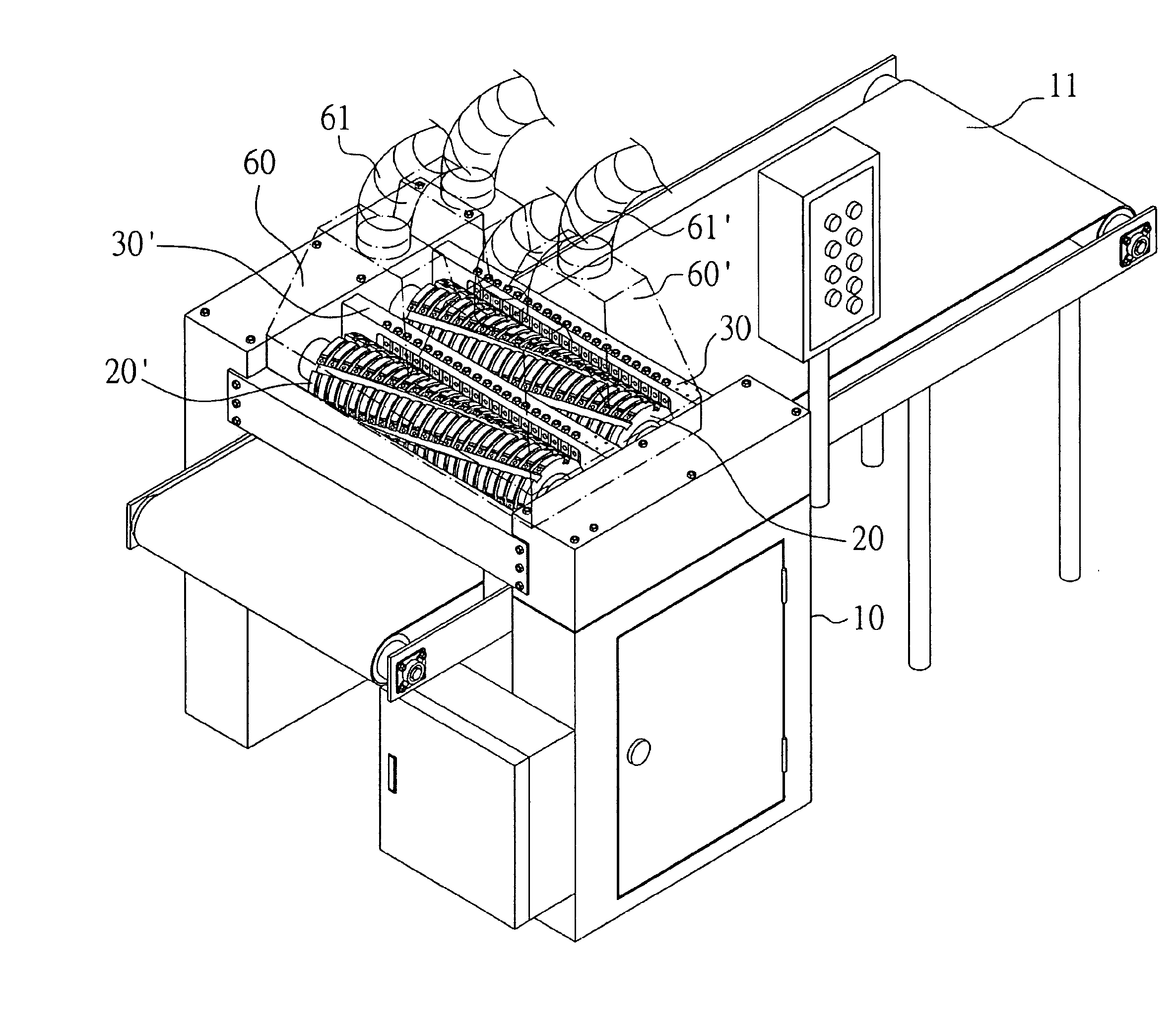

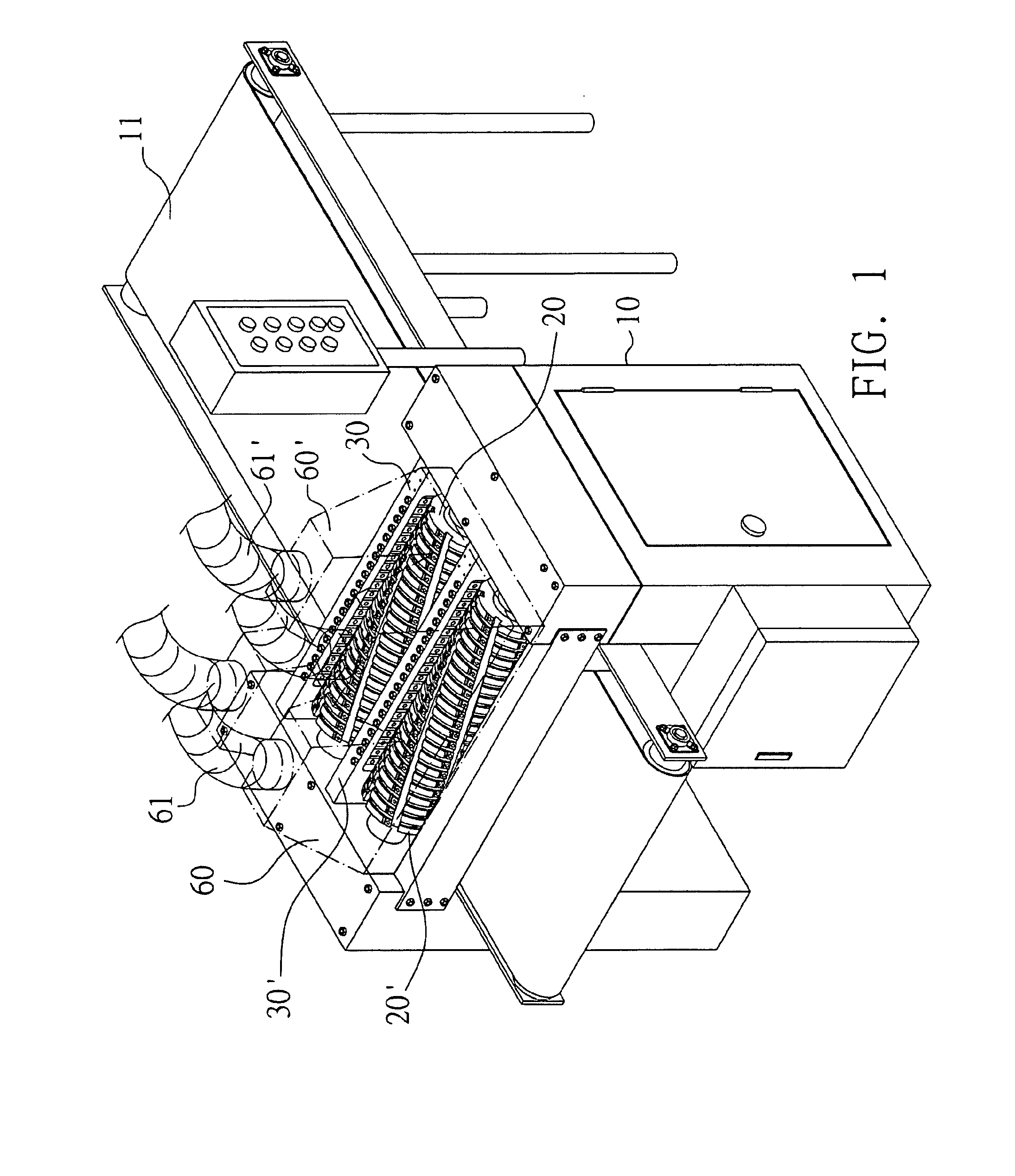

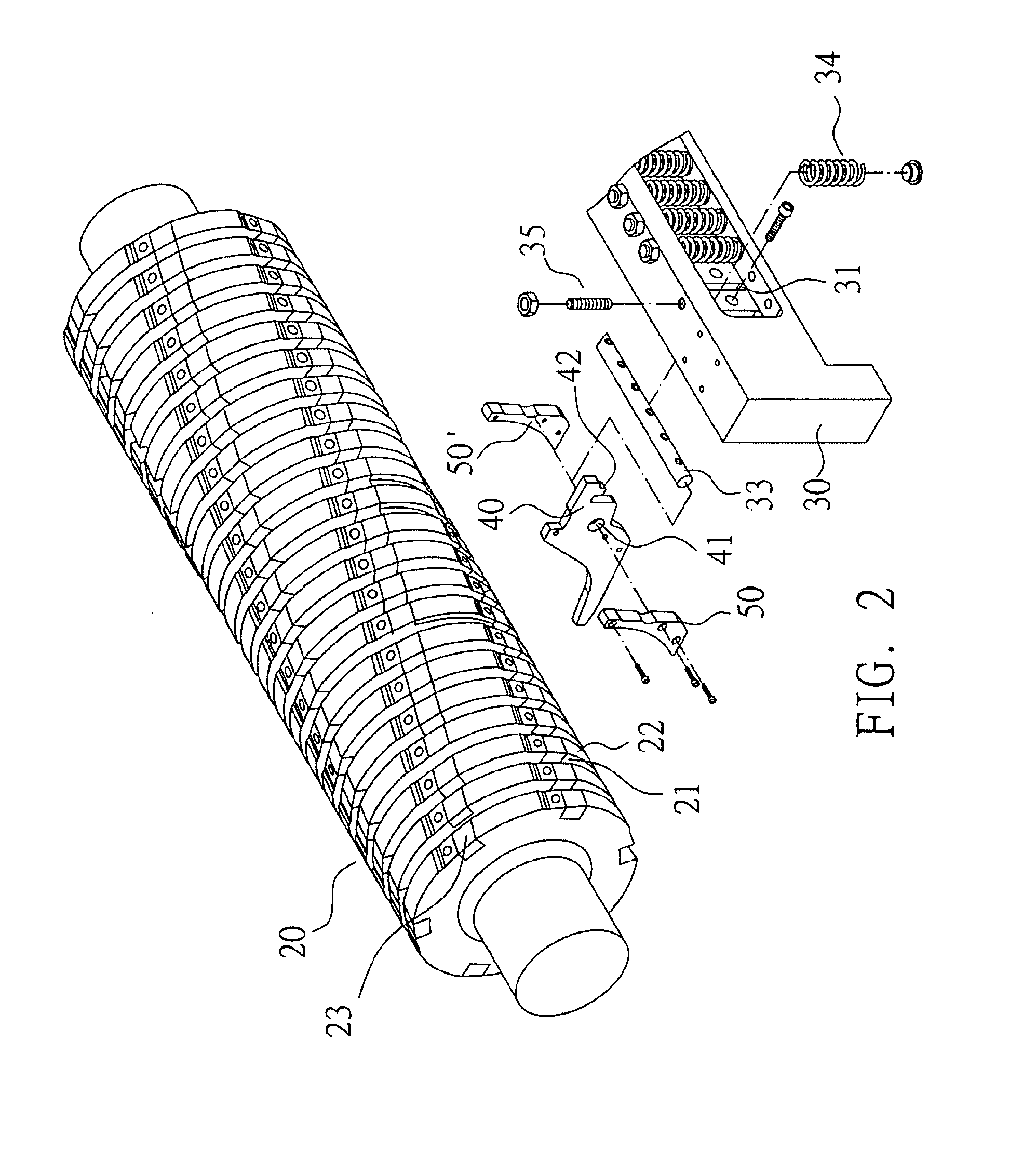

[0019]Referring to FIG. 1 for a perspective view of a structure of the invention, FIGS. 2 and 3 for exploded views of a structure and a portion of a structure of the invention respectively, and FIGS. 4 to 6 for views or a structure of the invention, a preferred embodiment of the invention comprises a machine platform 10, a pair of parallel knife shafts 20, 20′ disposed above the machine platform 10, a set of conveyor belt 11 passed below the pair of knife shafts 20, 20′ for conveying a wood veneer 1 placed on the conveyor belt 11 to the knife shafts 20, 20′, and carrying out a planing operation to a wood veneer 1 by using knife tools 23, 23′ installed on the knife shafts 20, 20′, a set of bases 30, 30′ disposed separately on a material feeding side of each knife shaft 20, 20′, a material pressing shoe 40, 40′ disposed separately at the bases 30, 30′ for pressing the wood veneer 1 appropriately to provide a stable planing operation, and a dust-collecting cover60, 60′ covered onto a spac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap