An online coating system for solar ultra-clear embossed glass

A technology of ultra-white patterned glass and coating system, applied in the field of solar ultra-white patterned glass production equipment, can solve the problems of complex production process, uneconomical materials, energy, labor, long consumption time, etc., and reduce production costs. , the effect of reducing production cost and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

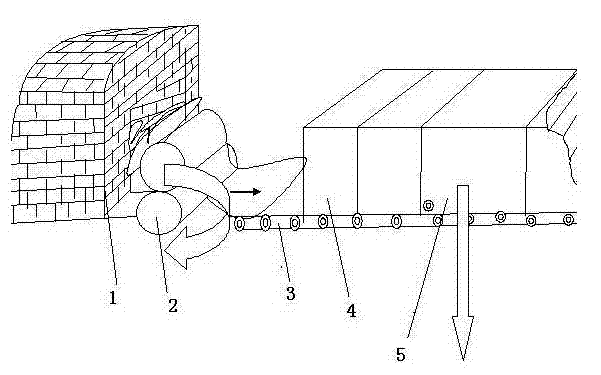

[0015] see figure 1 , 2 , which is a structural schematic diagram of an online coating system for solar ultra-clear patterned glass according to the present invention. As shown in the figure: the system includes a glass melting furnace 1, a calender 2 and a movable table 3 connected in sequence, and an annealing furnace 4 is set on the movable table 3; Coating control room 5.

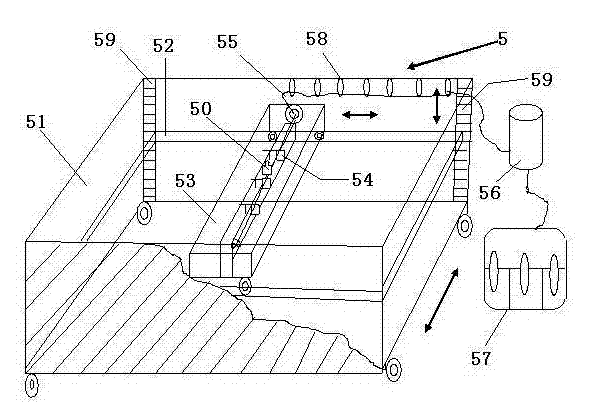

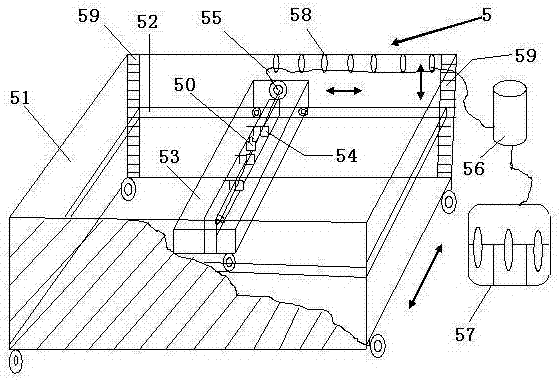

[0016] Specifically, such as figure 2 : the silicon dioxide coating control room 5 includes a spray box 51, a bridge 53 that can slide on a horizontal guide rail 52 arranged in the spray box 51 and a spray gun 54 arranged on the bridge 53. The feeding port of the spray gun 54 is connected with a vibrating powder feeder 56 controlled by a control chamber 57 through a pipeline 55 . The spray box 51 has an annular wire frame 58 on which the pipeline 55 hangs. The spraying box 51 further has a rack 59 arranged vertically, and the two ends of the horizontal guide rail 52 are movably connected with the rac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap