Sandwich setter plate

A setter and sandwich technology, which is applied in the field of sandwich setters, can solve the problems of product rolling, easy rolling of products, and affecting the normal operation of tunnel kilns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

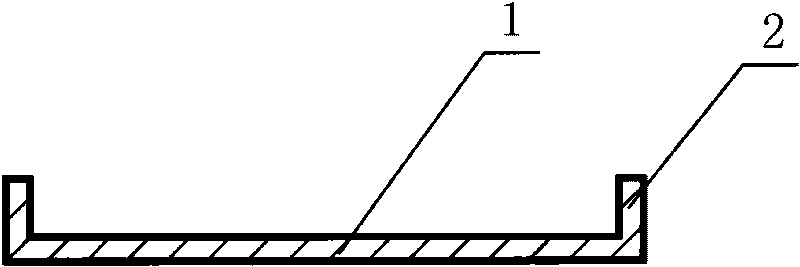

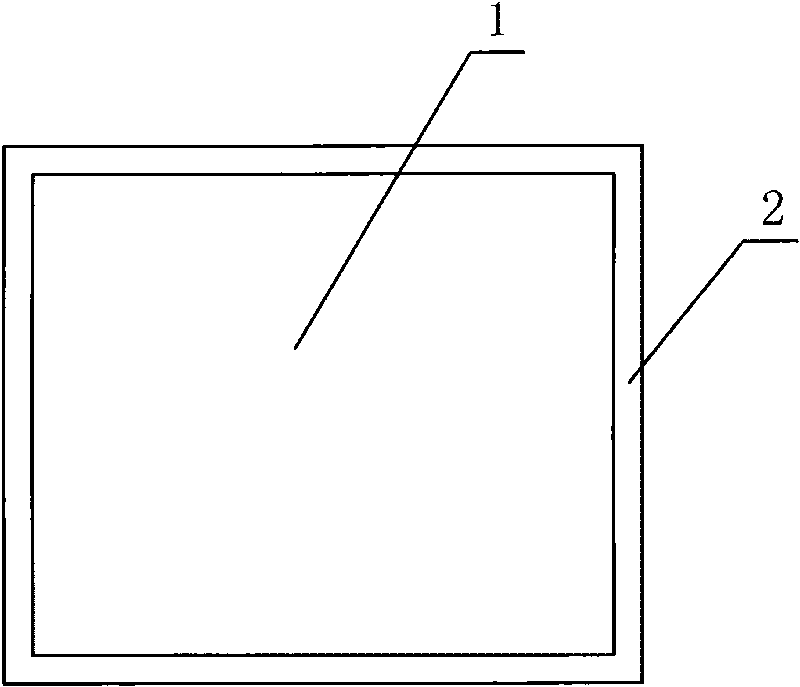

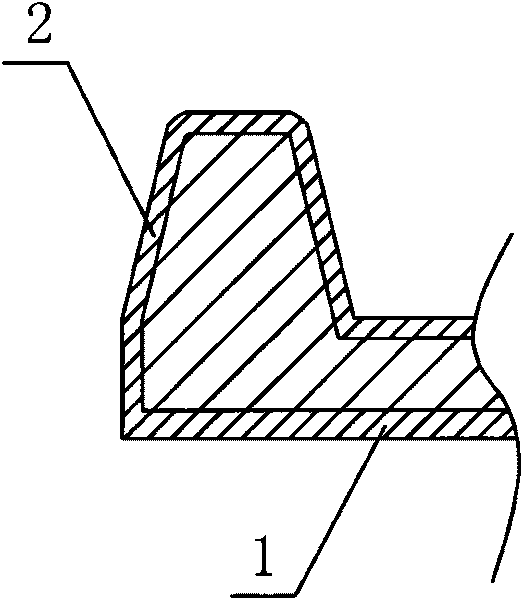

[0017] Such as figure 1 , figure 2 and image 3 As shown, a sandwich setter includes a setter main body 1 , and short side baffles 2 are arranged on the peripheral edges of the setter main body 1 . The height of the short side baffle 2 is 3-15mm. The width of the short edge baffle 2 is close to or slightly thinner than the thickness of the setter main body 1 . Both sides of the short-side baffle 2 adopt a hypotenuse structure, and the top of the short-side baffle 2 adopts a flat-angle structure. The setter main body 1 and the short side baffle 2 adopt an integral structure.

Embodiment 2

[0019] Such as figure 1 , figure 2 and Figure 4 As shown, a sandwich setter includes a setter main body 1 , and short side baffles 2 are arranged on the peripheral edges of the setter main body 1 . The height of the short side baffle 2 is 3-15mm. Both sides of the short-side baffle 2 adopt a hypotenuse structure, and the top of the short-side baffle 2 adopts a circular arc structure. The arc transition is adopted to avoid scratches. The setter main body 1 and the short side baffle 2 adopt an integral structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap