Method and device for achieving bi-directional stepping of kiln car on assembling and disassembling rail

A technology for loading and unloading rails and kiln cars, which is applied to the types of furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of low production efficiency, high labor intensity, and laboriousness, and achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

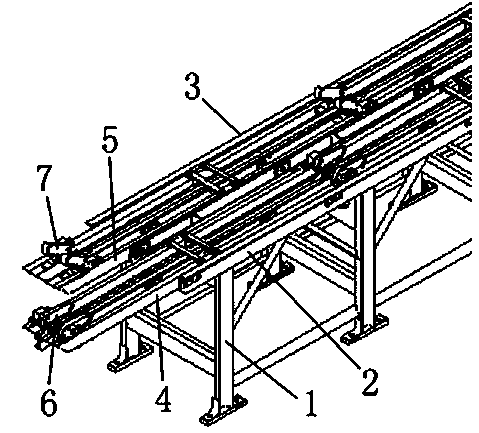

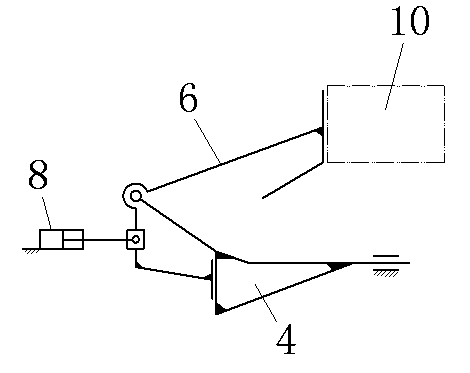

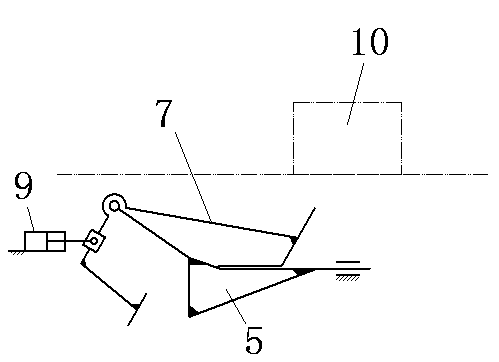

[0020] The method to realize the two-way stepping of the kiln car on the loading and unloading rail, such as figure 1 and figure 2 As shown, the method realizes the two-way movement function of the kiln car on the loading and unloading rail by alternately working two sets of pushing devices installed on the loading and unloading rail that are parallel to each other and opposite in pushing direction; by adjusting the stroke of the hydraulic cylinder on the pushing device to control The stepping distance is equal to the length of the kiln car. The propulsion device such as image 3 As shown, it includes a hydraulic cylinder. When the piston rod of the hydraulic cylinder is stretched out, it pushes the shifting block hinged on the horizontal movable frame to rotate. When the force point on the shifting b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap